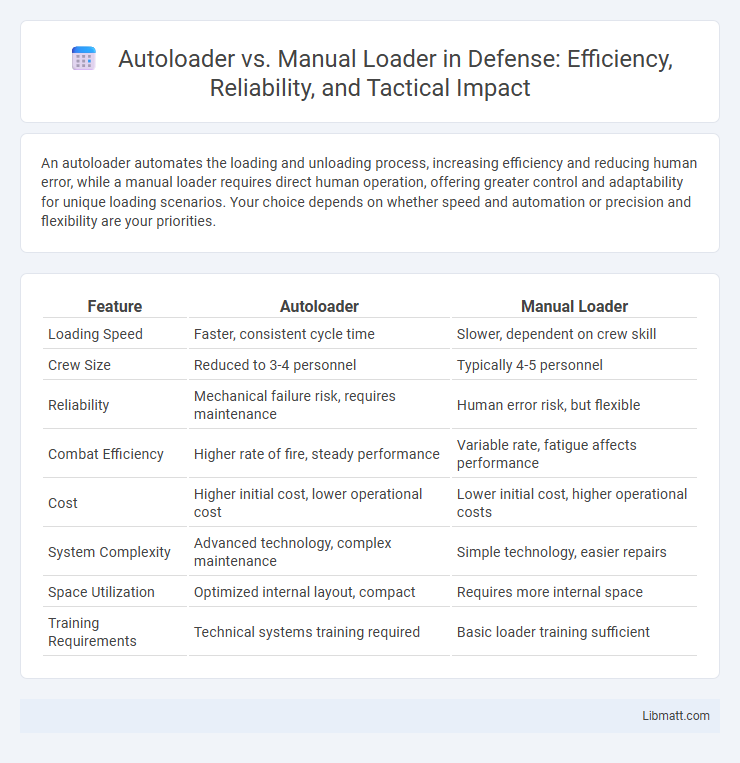

An autoloader automates the loading and unloading process, increasing efficiency and reducing human error, while a manual loader requires direct human operation, offering greater control and adaptability for unique loading scenarios. Your choice depends on whether speed and automation or precision and flexibility are your priorities.

Table of Comparison

| Feature | Autoloader | Manual Loader |

|---|---|---|

| Loading Speed | Faster, consistent cycle time | Slower, dependent on crew skill |

| Crew Size | Reduced to 3-4 personnel | Typically 4-5 personnel |

| Reliability | Mechanical failure risk, requires maintenance | Human error risk, but flexible |

| Combat Efficiency | Higher rate of fire, steady performance | Variable rate, fatigue affects performance |

| Cost | Higher initial cost, lower operational cost | Lower initial cost, higher operational costs |

| System Complexity | Advanced technology, complex maintenance | Simple technology, easier repairs |

| Space Utilization | Optimized internal layout, compact | Requires more internal space |

| Training Requirements | Technical systems training required | Basic loader training sufficient |

Introduction to Loaders: Autoloader vs Manual Loader

Loaders play a crucial role in managing how data is ingested and processed within data platforms, with autoloaders automatically detecting and loading new files, streamlining workflows and reducing manual intervention. Manual loaders require explicit user commands to ingest data, offering granular control but increasing the potential for human error and latency. Your choice between autoloader and manual loader hinges on balancing automation efficiency versus control over data loading processes.

Understanding How Autoloaders Work

Autoloaders automatically load PHP classes when they are needed, eliminating the need for manual include or require statements by registering a callback function with spl_autoload_register(). This mechanism improves code organization and reduces errors caused by missing file inclusions. In contrast, manual loaders require explicit file loading, which can be cumbersome and prone to maintenance issues in larger projects.

Manual Loading: Processes and Challenges

Manual loading involves physically placing ammunition into a weapon system, requiring trained personnel to handle and feed rounds accurately under various conditions. This process demands precision and speed to maintain firing efficiency while minimizing the risk of jams or misfires. Challenges include increased crew fatigue, slower reload times, and higher exposure to combat hazards compared to automated systems.

Key Differences Between Autoloaders and Manual Loaders

Autoloaders automatically feed ammunition into firearms using mechanisms like belts or magazines, increasing firing speed and reducing user effort, whereas manual loaders require the shooter to load each round individually. Autoloaders are typically found in machine guns or semi-automatic rifles, providing rapid fire capabilities, while manual loaders are common in bolt-action or lever-action firearms requiring manual cycling. The choice impacts operational efficiency, with autoloaders enhancing combat readiness and manual loaders offering greater control and reliability in specific scenarios.

Advantages of Using an Autoloader

Autoloaders offer significant advantages such as increased loading speed, improved safety by minimizing exposure to harsh environments, and enhanced operational efficiency due to automated processes. Your workflow benefits from reduced physical strain and lower risk of human error, leading to consistent and reliable ammunition handling. These systems also support faster response times in tactical situations, ensuring your readiness with minimal downtime.

Benefits and Limitations of Manual Loading

Manual loading allows precise control over the loading process, minimizing errors in handling sensitive or irregularly shaped materials. It is cost-effective for small-scale operations with limited automation budgets, requiring minimal initial investment and maintenance. However, manual loading is labor-intensive, prone to human error, and less efficient for high-volume production compared to automated autoloaders.

Performance Comparison: Autoloader vs Manual Loader

Autoloaders significantly enhance performance by automating class loading, reducing manual code maintenance and minimizing errors, which leads to faster development cycles compared to manual loaders. Manual loaders rely on explicit include or require statements, increasing the risk of redundant or missing file calls that can slow down execution and complicate debugging. Benchmark tests often show autoloaders delivering improved execution speed and scalability due to optimized file loading mechanisms and better integration with modern development frameworks.

Security Considerations for Both Approaches

Autoloaders enhance security by reducing user handling of ammunition, minimizing risks of accidental discharge or unauthorized access. Manual loaders offer more control, allowing you to carefully inspect each round but increase exposure to handling errors or unsafe loading practices. Implementing secure storage and strict protocols is essential for both to maintain safety and prevent firearm misuse.

Best Use Cases for Autoloaders and Manual Loaders

Autoloaders excel in high-volume shooting scenarios such as military applications, law enforcement, and competitive shooting where rapid, consistent feeding increases efficiency and reduces reload times. Manual loaders are best suited for precision shooting, hunting, and situations requiring careful ammunition selection, offering greater control over each round loaded. Both systems cater to specific needs: autoloaders prioritize speed and convenience, while manual loaders emphasize deliberate accuracy and reliability.

Conclusion: Choosing Between Autoloader and Manual Loader

Choosing between an autoloader and a manual loader depends on your operational priorities, such as efficiency, cost, and control. Autoloaders offer faster loading times and reduced labor costs, ideal for high-volume or automated environments, while manual loaders provide greater flexibility and precision, suited for specialized tasks or budget-conscious setups. Assess your specific workflow requirements and resource availability to determine which loader best aligns with your productivity goals.

autoloader vs manual loader Infographic

libmatt.com

libmatt.com