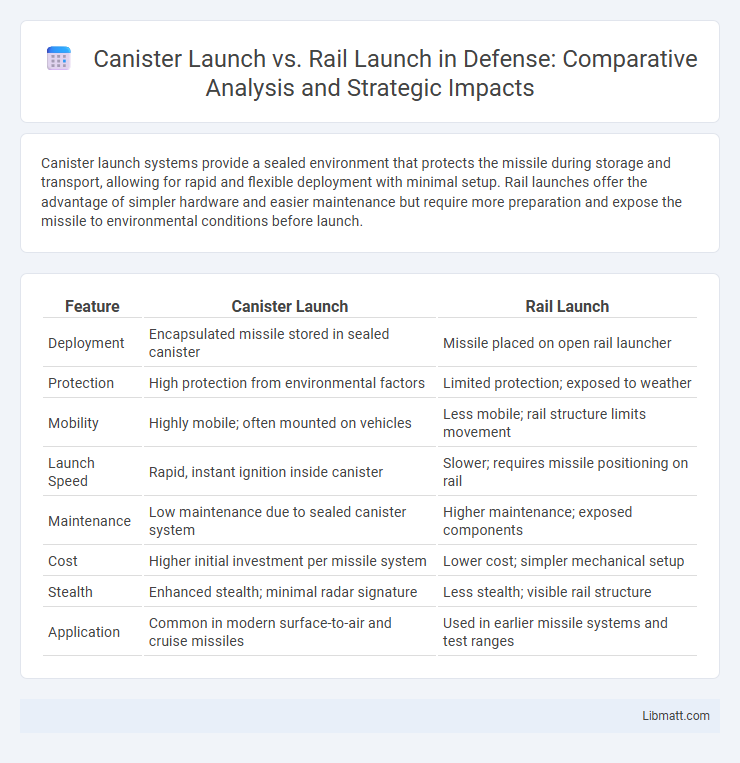

Canister launch systems provide a sealed environment that protects the missile during storage and transport, allowing for rapid and flexible deployment with minimal setup. Rail launches offer the advantage of simpler hardware and easier maintenance but require more preparation and expose the missile to environmental conditions before launch.

Table of Comparison

| Feature | Canister Launch | Rail Launch |

|---|---|---|

| Deployment | Encapsulated missile stored in sealed canister | Missile placed on open rail launcher |

| Protection | High protection from environmental factors | Limited protection; exposed to weather |

| Mobility | Highly mobile; often mounted on vehicles | Less mobile; rail structure limits movement |

| Launch Speed | Rapid, instant ignition inside canister | Slower; requires missile positioning on rail |

| Maintenance | Low maintenance due to sealed canister system | Higher maintenance; exposed components |

| Cost | Higher initial investment per missile system | Lower cost; simpler mechanical setup |

| Stealth | Enhanced stealth; minimal radar signature | Less stealth; visible rail structure |

| Application | Common in modern surface-to-air and cruise missiles | Used in earlier missile systems and test ranges |

Introduction to Missile Launch Systems

Missile launch systems primarily use canister launch and rail launch methods, each designed for specific operational environments. Canister launches provide enclosed, protected storage and transport, enabling rapid and safe missile deployment under harsh conditions. Your choice between these systems depends on factors like mobility requirements, environmental exposure, and launch readiness efficiency.

Overview of Canister Launch Systems

Canister launch systems utilize a sealed tube or container to house and protect missiles or projectiles during storage and launch, allowing for rapid deployment and improved mobility. These systems provide enhanced safety by isolating the missile from external elements and reducing launch preparation time compared to traditional rail launch methods. Canister launches offer versatility across various platforms, including naval vessels, ground vehicles, and mobile launchers, supporting a wide range of missile types such as cruise missiles, anti-ship missiles, and ballistic missiles.

Overview of Rail Launch Systems

Rail launch systems utilize a guided rail to accelerate missiles or projectiles during their initial phase, ensuring precise direction and stability. These systems offer advantages in compact storage and rapid deployment, making them suitable for naval and land-based platforms. Your choice between canister and rail launch depends on operational requirements such as space constraints and target engagement scenarios.

Key Differences Between Canister and Rail Launch

Canister launch systems provide enclosed protection for missiles during storage and transport, enabling rapid vertical deployment and reducing vulnerability to environmental factors. Rail launch setups involve missiles mounted externally on a rail, allowing for horizontal launch trajectories and often requiring more extensive infrastructure but offering easier maintenance access. The key differences lie in canister launch's compact, sealed mobilization versus rail launch's exposed, infrastructure-dependent deployment, affecting strategic mobility and launch readiness.

Advantages of Canister Launch

Canister launch systems offer enhanced mobility and rapid deployment capabilities compared to rail launch methods, enabling efficient transportation and launch from diverse terrains. The enclosed canister protects missile components from environmental factors, improving reliability and reducing maintenance costs. Furthermore, canister launches provide quicker launch readiness and safer storage conditions, increasing operational flexibility for military applications.

Advantages of Rail Launch

Rail launch offers precise guidance during missile or rocket deployment, minimizing drift and enhancing accuracy compared to canister launch. Its robust support structure allows for handling larger payloads and provides flexibility in adjusting launch angles, optimizing trajectory control. Your mission benefits from increased reliability and consistent performance in diverse environmental conditions through rail launch systems.

Operational Considerations and Flexibility

Canister launch systems offer enhanced operational flexibility through rapid deployment and simplified handling, enabling quick launch sequences in diverse environments without extensive infrastructure. Rail launch systems require more complex ground support, limiting mobility but providing robust guidance during initial launch phases, which benefits heavy payload accuracy and stability. Operational considerations must weigh the trade-off between the canister's versatility and the rail's precision, tailored to mission requirements and logistical constraints.

Safety and Maintenance Comparison

Canister launch systems offer enhanced safety by enclosing the missile, protecting it from environmental factors and reducing accidental ignition risks compared to rail launch systems, which expose the missile during preparation and launch. Maintenance requirements for canister launches are generally lower due to sealed storage, minimizing corrosion and mechanical wear, whereas rail launch setups demand frequent inspections and upkeep of exposed rails and support structures. Your choice between these systems should consider the operational environment and maintenance capabilities to ensure reliable and safe missile deployment.

Application Scenarios: Canister vs Rail Launch

Canister launch systems are primarily used for portable, short-range missile deployments, ideal for rapid response and mobility in confined or urban environments. Rail launch setups support heavier, long-range missiles and are common in fixed defense installations or naval vessels, offering greater structural support and stability for large-scale payloads. The canister design enhances protection and quick reload capabilities, while rail launch systems provide advantages in precision alignment and larger missile compatibility.

Future Trends in Missile Launch Technologies

Future trends in missile launch technologies emphasize canister launch systems due to their enhanced mobility, rapid deployment capabilities, and improved survivability in varied terrains compared to traditional rail launch platforms. Innovations in canister designs incorporate advanced materials and automated launch sequences, enabling quicker response times and increased operational flexibility. Integration of AI-driven targeting and launch control systems further distinguishes canister launches as the preferred choice for next-generation tactical and strategic missile systems.

canister launch vs rail launch Infographic

libmatt.com

libmatt.com