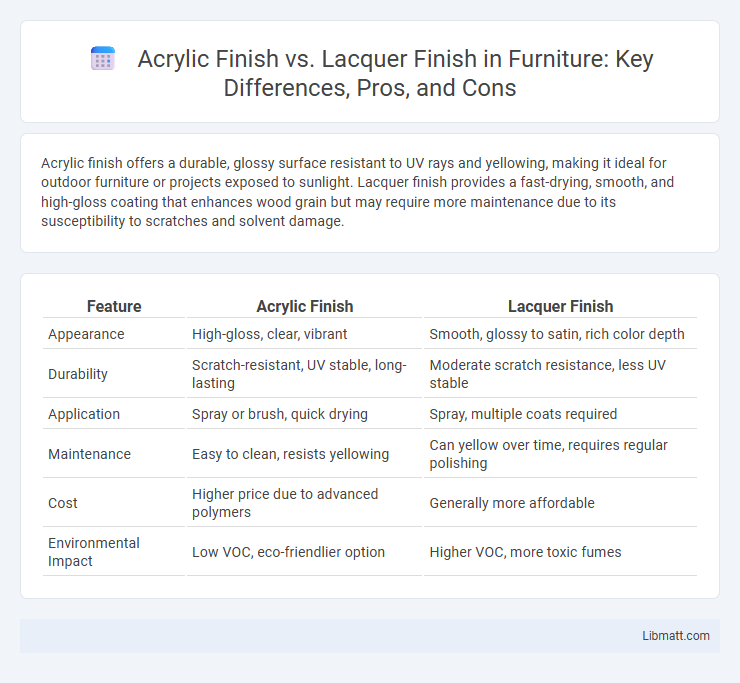

Acrylic finish offers a durable, glossy surface resistant to UV rays and yellowing, making it ideal for outdoor furniture or projects exposed to sunlight. Lacquer finish provides a fast-drying, smooth, and high-gloss coating that enhances wood grain but may require more maintenance due to its susceptibility to scratches and solvent damage.

Table of Comparison

| Feature | Acrylic Finish | Lacquer Finish |

|---|---|---|

| Appearance | High-gloss, clear, vibrant | Smooth, glossy to satin, rich color depth |

| Durability | Scratch-resistant, UV stable, long-lasting | Moderate scratch resistance, less UV stable |

| Application | Spray or brush, quick drying | Spray, multiple coats required |

| Maintenance | Easy to clean, resists yellowing | Can yellow over time, requires regular polishing |

| Cost | Higher price due to advanced polymers | Generally more affordable |

| Environmental Impact | Low VOC, eco-friendlier option | Higher VOC, more toxic fumes |

Introduction to Acrylic and Lacquer Finishes

Acrylic finishes are water-based coatings known for their durability, clarity, and resistance to yellowing, making them ideal for furniture and automotive applications. Lacquer finishes, often solvent-based, provide a high-gloss, fast-drying surface favored for its smooth, hard, and polished appearance on wood and metal surfaces. Both finishes offer distinct advantages in protection and aesthetics, with acrylic excelling in environmental safety and flexibility, while lacquer delivers a traditional, high-shine effect.

Composition and Chemical Properties

Acrylic finish consists of synthetic resins derived from acrylic acid, offering excellent UV resistance and flexibility, making it resistant to cracking and yellowing. Lacquer finish is composed of nitrocellulose or acrylic polymers dissolved in solvents, which dry quickly through solvent evaporation, creating a hard, durable, and glossy surface. Your choice between acrylic and lacquer finishes should consider the chemical stability and desired durability for specific applications.

Application Methods Compared

Acrylic finishes are typically applied using a brush, spray, or roller, offering versatility and ease for both DIY projects and professional work. Lacquer finishes require spray application for a smooth, high-gloss surface, often necessitating specialized equipment and skilled technique. Choosing between acrylic and lacquer depends on your project's complexity and the level of durability or sheen you desire.

Drying and Curing Times

Acrylic finish typically dries faster than lacquer finish, with surface drying occurring within 1 to 2 hours, while lacquer can take several hours to become tack-free. However, lacquer finishes cure more thoroughly through solvent evaporation, often requiring 24 to 48 hours or more to achieve full hardness and durability. Understanding these drying and curing times helps you choose the best finish for your project's timeline and durability needs.

Durability and Resistance

Acrylic finish offers strong durability with excellent resistance to UV rays, yellowing, and cracking, making it ideal for areas exposed to sunlight and moisture. Lacquer finish provides a hard, durable surface with superior scratch and chemical resistance but tends to be more susceptible to chipping and fading over time. Both finishes deliver protective coatings, yet acrylic excels in weather resistance while lacquer is favored for its smooth, high-gloss appearance and hardness.

Visual Appearance and Aesthetic Qualities

Acrylic finish offers a clear, glossy appearance that enhances the natural color and texture of wood with a durable, non-yellowing coating. Lacquer finish provides a highly reflective, smooth surface with a rich depth and warmth that can accentuate intricate details or grain patterns. Your choice influences the overall visual appeal, with acrylic delivering modern clarity, while lacquer offers a classic, polished look.

Maintenance and Cleaning Requirements

Acrylic finish demands minimal maintenance, requiring gentle cleaning with mild soap and water to prevent clouding or damage. Lacquer finish needs more frequent attention, as it is sensitive to abrasives and solvents, necessitating careful dusting and polish with specific lacquer-safe products to maintain its glossy appearance. Both finishes benefit from avoiding harsh chemicals and using soft cloths to preserve their protective layers and aesthetic appeal.

Environmental Impact and Safety

Acrylic finishes generally have a lower environmental impact due to their water-based formulas, emitting fewer volatile organic compounds (VOCs) compared to traditional lacquer finishes, which are solvent-based and release higher levels of harmful VOCs. Your choice of acrylic finish supports better indoor air quality and reduces exposure to toxic fumes during application, contributing to safer working conditions and less environmental pollution. Both finishes require proper ventilation and handling, but acrylic's eco-friendlier composition makes it a safer and more sustainable option.

Cost Analysis: Acrylic vs. Lacquer

Acrylic finish typically costs more upfront than lacquer due to higher material prices and longer application times, but it offers superior durability and UV resistance that can reduce long-term maintenance expenses. Lacquer finish is often less expensive initially and dries quickly, making it cost-effective for projects with tight timelines or budget constraints. Your choice depends on balancing immediate costs with the desired lifespan and appearance of the finished surface.

Best Uses and Practical Recommendations

Acrylic finishes provide excellent UV resistance and flexibility, making them ideal for outdoor furniture and high-traffic surfaces where durability is essential. Lacquer finishes offer a high-gloss, smooth appearance suited for indoor items like cabinets and musical instruments, providing quick drying and easy repairability. For your projects, choose acrylic if you need weather protection and longevity, while lacquer is best for a refined, polished look on interior woodwork.

Acrylic finish vs lacquer finish Infographic

libmatt.com

libmatt.com