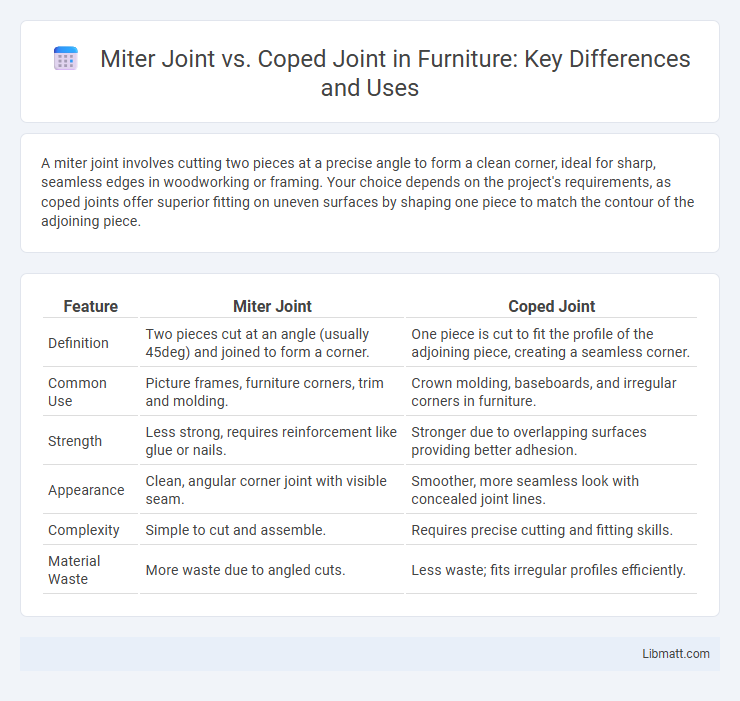

A miter joint involves cutting two pieces at a precise angle to form a clean corner, ideal for sharp, seamless edges in woodworking or framing. Your choice depends on the project's requirements, as coped joints offer superior fitting on uneven surfaces by shaping one piece to match the contour of the adjoining piece.

Table of Comparison

| Feature | Miter Joint | Coped Joint |

|---|---|---|

| Definition | Two pieces cut at an angle (usually 45deg) and joined to form a corner. | One piece is cut to fit the profile of the adjoining piece, creating a seamless corner. |

| Common Use | Picture frames, furniture corners, trim and molding. | Crown molding, baseboards, and irregular corners in furniture. |

| Strength | Less strong, requires reinforcement like glue or nails. | Stronger due to overlapping surfaces providing better adhesion. |

| Appearance | Clean, angular corner joint with visible seam. | Smoother, more seamless look with concealed joint lines. |

| Complexity | Simple to cut and assemble. | Requires precise cutting and fitting skills. |

| Material Waste | More waste due to angled cuts. | Less waste; fits irregular profiles efficiently. |

Introduction to Miter Joint vs Coped Joint

Miter joints are created by beveling two pieces of material, typically at a 45-degree angle, to form a clean corner joint, commonly used in picture frames and trim work. Coped joints involve shaping the end of one piece to fit the profile of another, providing a tighter and more precise fit, especially for inside corners in crown molding and baseboards. Your choice between miter and coped joints affects both the aesthetic and durability of the finished project, emphasizing the importance of selecting the appropriate technique for seamless interior trim installation.

Basic Definition of Miter Joint

A miter joint is a woodworking technique where two pieces are cut at an angle, usually 45 degrees, and joined to form a corner, creating a seamless, clean edge. This joint is commonly used in picture frames, molding, and trim work to achieve aesthetically pleasing corners without visible end grain. Understanding the basic definition of a miter joint helps you choose the right method for sharp, precise inside or outside corners in your carpentry projects.

Basic Definition of Coped Joint

A coped joint is a woodworking technique where the end of one molding is shaped to fit the contour of the adjoining piece, ensuring a tight and seamless fit, especially around inside corners. Unlike a miter joint, which cuts both pieces at an angle to form a corner, the coped joint involves profiling one piece to match the profile of the other. This technique offers greater precision and durability in trim work, preventing gaps caused by wood expansion or contraction, making it ideal for achieving a cleaner finish in your projects.

Applications of Miter Joints

Miter joints are commonly used in picture frames, door frames, and decorative trim work where a clean, angled edge is essential for aesthetic appeal. These joints provide seamless corner connections that enhance the visual continuity of moldings and cabinetry. Their precision makes them ideal for woodworking projects requiring tight, right-angled corners that are both strong and visually pleasing.

Applications of Coped Joints

Coped joints are commonly used in interior trim and molding applications where fitting pieces around irregular shapes or existing profiles is required. Their ability to create precise, tight-fitting connections along uneven surfaces makes them ideal for baseboards, crown moldings, and chair rails. You benefit from enhanced aesthetic appeal and structural integrity, especially in corners that are not perfectly square.

Strength Comparison: Miter vs Coped Joints

Coped joints offer superior strength compared to miter joints due to the increased surface area for adhesive and mechanical fastening, reducing the risk of joint failure under stress. Miter joints, while aesthetically clean with seamless corner alignment, tend to be weaker as they rely on end-grain adhesion, which is less durable. When choosing between the two, your project's structural integrity is best supported by coped joints, especially in trim and molding applications where lasting strength is crucial.

Aesthetic Differences Between Miter and Coped Joints

Miter joints provide a clean, angled seam that creates a uniform, geometric look often favored for modern trim work. Coped joints offer a more traditional, seamless appearance by fitting one piece of molding precisely against the profile of another, hiding gaps caused by uneven walls. Your choice between these joints will impact the visual flow and refinement of moldings in your space.

Installation Process: Miter Joint vs Coped Joint

The installation process for a miter joint involves cutting two pieces at precise angles, usually 45 degrees, to form a seamless corner, making it more straightforward but requiring accurate measurements and cuts. Coped joints, on the other hand, entail shaping one piece to fit the contour of the other, especially useful for inside corners with irregular profiles, which demands more skill and time during installation. Your choice between these joints should consider the ease of installation and the desired finish quality, with miter joints being quicker, while coped joints provide tighter, less gap-prone fits.

Tools Required for Each Joint Type

Creating a miter joint primarily requires a miter saw or a miter box with a backsaw to achieve precise angled cuts, along with clamps for securing the pieces during assembly. Coped joints necessitate a coping saw or a jigsaw to carefully trim the profile of one molding piece to fit snugly against the face of another, alongside files or sandpaper for fine-tuning the fit. Both joint types benefit from measuring tools, such as a combination square or protractor, to ensure accurate angles and clean, professional results.

Choosing the Right Joint for Your Project

Selecting between a miter joint and a coped joint depends on the type of trim and desired finish quality; miter joints are ideal for straight, clean 45-degree cuts often used in picture frames and simple moldings. Coped joints excel in coping complex profiles, allowing for tighter fits against inside corners and minimizing gaps caused by wall irregularities. For durability and aesthetic precision in interior trim, coped joints are preferred in crown moldings, whereas miter joints suit simpler, external corner applications.

miter joint vs coped joint Infographic

libmatt.com

libmatt.com