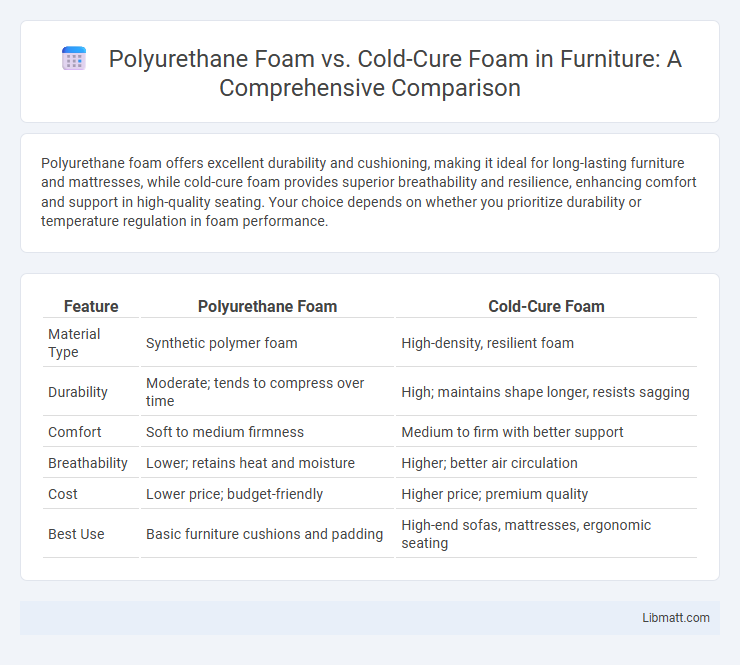

Polyurethane foam offers excellent durability and cushioning, making it ideal for long-lasting furniture and mattresses, while cold-cure foam provides superior breathability and resilience, enhancing comfort and support in high-quality seating. Your choice depends on whether you prioritize durability or temperature regulation in foam performance.

Table of Comparison

| Feature | Polyurethane Foam | Cold-Cure Foam |

|---|---|---|

| Material Type | Synthetic polymer foam | High-density, resilient foam |

| Durability | Moderate; tends to compress over time | High; maintains shape longer, resists sagging |

| Comfort | Soft to medium firmness | Medium to firm with better support |

| Breathability | Lower; retains heat and moisture | Higher; better air circulation |

| Cost | Lower price; budget-friendly | Higher price; premium quality |

| Best Use | Basic furniture cushions and padding | High-end sofas, mattresses, ergonomic seating |

Understanding Polyurethane Foam

Polyurethane foam is a versatile material widely used for insulation, cushioning, and packaging due to its excellent thermal properties and durability. This foam is created through a chemical reaction between polyols and diisocyanates, resulting in a flexible, lightweight material that adapts to various applications. Understanding the composition and benefits of polyurethane foam helps you choose the right solution for comfort and protection needs.

What is Cold-Cure Foam?

Cold-cure foam, also known as cold molding foam, is a type of high-resilience polyurethane material cured at lower temperatures to enhance durability and elasticity. Unlike standard polyurethane foam, cold-cure foam undergoes a slower curing process that increases density and support, making it ideal for high-end furniture and mattress applications. This foam's superior breathability and long-lasting comfort distinguish it as a premium alternative in cushioning products.

Key Differences Between Polyurethane and Cold-Cure Foam

Polyurethane foam is a versatile, general-purpose material commonly used in furniture, bedding, and insulation due to its lightweight and flexible properties, while cold-cure foam is specifically formulated for high resilience and durability, often preferred in premium mattresses and upholstery for its enhanced comfort and longevity. The production process differentiates them significantly; polyurethane foam is produced through a faster reaction at room temperature, whereas cold-cure foam undergoes a slower curing process at lower temperatures, resulting in a denser and more robust foam structure. Performance-wise, polyurethane foam tends to have lower breathability and durability compared to cold-cure foam, which offers superior support, resistance to deformation, and better moisture regulation.

Durability Comparison: Polyurethane vs Cold-Cure Foam

Polyurethane foam offers high durability with excellent resilience and resistance to wear, making it suitable for long-term use in furniture and insulation applications. Cold-cure foam provides superior strength and stability due to its chemical curing process, which results in enhanced density and improved lifespan compared to standard polyurethane foam. While polyurethane foam excels in flexibility and cost-effectiveness, cold-cure foam outperforms in durability, maintaining its shape and structural integrity under prolonged stress.

Comfort and Support: Which Foam Performs Better?

Polyurethane foam offers excellent durability and firm support, making it ideal for those seeking long-lasting comfort with consistent firmness. Cold-cure foam provides superior breathability and pressure relief, adapting better to body contours for enhanced comfort during extended use. Choosing between these foams depends on whether your priority is resilient support or adaptive cushioning for your mattress or seating needs.

Applications in Furniture and Mattresses

Polyurethane foam offers versatile cushioning used widely in furniture and mattresses due to its durability and density variations, making it ideal for seating, cushions, and supportive mattress layers. Cold-cure foam provides superior breathability and resilience, often preferred in premium mattresses and high-end furniture for enhanced comfort and longevity. Understanding your specific needs helps determine whether the firm support of polyurethane or the breathable comfort of cold-cure foam best suits your furniture and mattress applications.

Breathability and Temperature Regulation

Polyurethane foam typically offers moderate breathability, making it less effective at temperature regulation compared to cold-cure foam, which features an open-cell structure allowing for superior airflow and moisture wicking. Cold-cure foam maintains a cooler sleeping surface by promoting ventilation and dissipating heat more efficiently, making it ideal for individuals prone to overheating. The enhanced breathability of cold-cure foam contributes to improved comfort by reducing heat retention and maintaining a balanced sleeping climate.

Cost Analysis: Polyurethane vs Cold-Cure Foam

Polyurethane foam generally has a lower initial cost compared to cold-cure foam, making it a budget-friendly option for many applications. Cold-cure foam, while more expensive upfront, offers superior durability and resilience, potentially reducing replacement and maintenance expenses over time. Your choice between polyurethane and cold-cure foam should consider both immediate costs and long-term value for optimal investment.

Environmental Impact and Sustainability

Polyurethane foam typically has a higher environmental impact due to its petrochemical origins and the release of volatile organic compounds (VOCs) during production. Cold-cure foam often uses less energy-intensive curing processes, reducing carbon emissions and making it a more sustainable choice for eco-conscious manufacturing. Both foams' recyclability and potential for incorporating bio-based raw materials significantly influence their overall sustainability profiles.

Choosing the Right Foam for Your Needs

Polyurethane foam offers excellent durability and versatility for a wide range of applications including furniture, insulation, and packaging, making it ideal for projects requiring long-lasting support and cushioning. Cold-cure foam, known for its superior breathability and comfort, is particularly suited for mattresses and seating where temperature regulation and softness are key factors. Evaluating your specific needs for firmness, resilience, and environmental impact will help you choose the right foam that enhances your comfort and meets practical requirements.

Polyurethane Foam vs Cold-Cure Foam Infographic

libmatt.com

libmatt.com