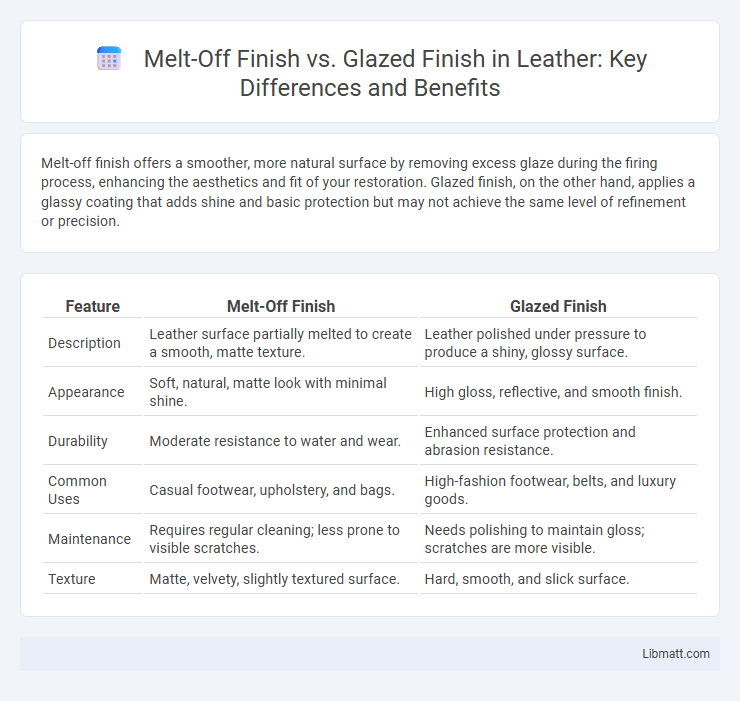

Melt-off finish offers a smoother, more natural surface by removing excess glaze during the firing process, enhancing the aesthetics and fit of your restoration. Glazed finish, on the other hand, applies a glassy coating that adds shine and basic protection but may not achieve the same level of refinement or precision.

Table of Comparison

| Feature | Melt-Off Finish | Glazed Finish |

|---|---|---|

| Description | Leather surface partially melted to create a smooth, matte texture. | Leather polished under pressure to produce a shiny, glossy surface. |

| Appearance | Soft, natural, matte look with minimal shine. | High gloss, reflective, and smooth finish. |

| Durability | Moderate resistance to water and wear. | Enhanced surface protection and abrasion resistance. |

| Common Uses | Casual footwear, upholstery, and bags. | High-fashion footwear, belts, and luxury goods. |

| Maintenance | Requires regular cleaning; less prone to visible scratches. | Needs polishing to maintain gloss; scratches are more visible. |

| Texture | Matte, velvety, slightly textured surface. | Hard, smooth, and slick surface. |

Introduction to Melt-off and Glazed Finishes

Melt-off finish involves a high-temperature process that removes surface impurities, resulting in a smoother and more durable coating ideal for metal and glass applications. Glazed finish, on the other hand, creates a glossy, protective layer by applying a thin, vitrified surface that enhances visual appeal and resistance to wear. Understanding the differences between Melt-off and glazed finishes helps you select the best option for aesthetic and functional needs in your projects.

Defining Melt-off Finish: Key Characteristics

Melt-off finish is characterized by its smooth, polished surface created through a controlled heating process that removes excess material, resulting in improved reflectivity and durability. This finish enhances the visual appeal while minimizing imperfections commonly found in glazed finishes, which rely on a glass-like coating applied after firing. Your choice of melt-off finish ensures a unique combination of aesthetic precision and long-lasting resilience ideal for high-quality ceramic or glass products.

Understanding Glazed Finish: Core Features

A glazed finish offers a smooth, glossy surface achieved through a high-temperature firing process that seals and enhances the material's natural colors and patterns. This finish provides increased durability and resistance to stains and scratches, making it ideal for kitchen countertops and bathroom surfaces. Understanding the core features of a glazed finish helps you select a surface that combines aesthetic appeal with long-lasting protection.

Application Processes Compared

Melt-off finish involves applying a heat treatment that removes excess coating by melting, resulting in a smooth, consistent surface ideal for metal and glass products. Glazed finish is achieved through a firing process that creates a glossy, hard surface by fusing a glaze layer onto ceramics or tiles. Melt-off finish is typically faster and used for precise surface control, while glazed finish provides enhanced durability and aesthetic appeal for decorative items.

Visual Differences: Melt-off vs Glazed

Melt-off finish offers a smooth, matte surface with a subtle texture that diffuses light, creating a soft, natural appearance ideal for reducing reflections. Glazed finish, by contrast, provides a glossy, reflective surface that enhances color vibrancy and highlights details with sharp clarity. Your choice between melt-off and glazed finishes significantly impacts the visual perception, whether prioritizing understated elegance or vivid, crisp imagery.

Durability and Maintenance Considerations

Melt-off finish offers superior durability due to its ability to resist scratches and abrasions, making it ideal for high-traffic areas with heavy use. Glazed finishes provide a smooth, glossy surface that enhances aesthetic appeal but may require more frequent maintenance to prevent surface wear and scratches over time. Maintenance of melt-off finishes typically involves simple cleaning with non-abrasive products, whereas glazed finishes benefit from regular polishing to maintain their shine and protect the surface integrity.

Best Uses for Melt-off Finishes

Melt-off finishes are ideal for applications requiring smooth, durable surfaces with enhanced resistance to wear and corrosion, making them perfect for industrial equipment, automotive parts, and cookware. This finish excels in environments subject to high friction or heat, providing long-lasting protection without compromising material integrity. Your choice of a melt-off finish ensures optimal performance where both aesthetics and functional durability are critical.

Ideal Applications for Glazed Finishes

Glazed finishes are ideal for applications requiring a glossy, smooth surface that enhances visual appeal and provides a protective barrier against moisture and stains. Commonly used on ceramic tiles, countertops, and bathroom fixtures, glazed finishes improve durability and ease of maintenance in high-traffic or wet areas. Your surfaces benefit from the added resistance and elegant look that glazed finishes consistently deliver.

Cost Comparison: Melt-off vs Glazed

Melt-off finishes generally cost less due to simpler application processes and reduced labor time compared to glazed finishes, which require multiple steps and specialized materials. Glazed finishes incur higher expenses because of intricate techniques that enhance surface texture and visual appeal, increasing production time. Choosing melt-off can lower overall manufacturing costs without compromising basic surface protection.

Choosing the Right Finish for Your Project

Melt-off finishes offer a smooth, matte appearance ideal for modern, understated designs, while glazed finishes provide a glossy, reflective surface that enhances color depth and detail. Selecting the right finish depends on the aesthetic and functional requirements of your project, with melt-off suits minimalist and contemporary spaces and glazed finishes favored for vibrant, high-traffic areas. Consider factors like durability, maintenance, and lighting to ensure the finish complements both the design vision and practical use of the space.

Melt-off finish vs glazed finish Infographic

libmatt.com

libmatt.com