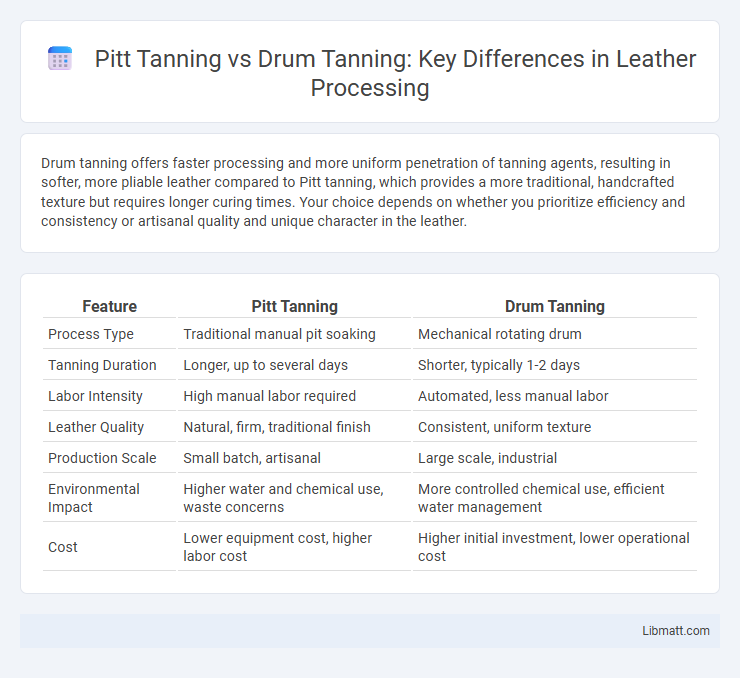

Drum tanning offers faster processing and more uniform penetration of tanning agents, resulting in softer, more pliable leather compared to Pitt tanning, which provides a more traditional, handcrafted texture but requires longer curing times. Your choice depends on whether you prioritize efficiency and consistency or artisanal quality and unique character in the leather.

Table of Comparison

| Feature | Pitt Tanning | Drum Tanning |

|---|---|---|

| Process Type | Traditional manual pit soaking | Mechanical rotating drum |

| Tanning Duration | Longer, up to several days | Shorter, typically 1-2 days |

| Labor Intensity | High manual labor required | Automated, less manual labor |

| Leather Quality | Natural, firm, traditional finish | Consistent, uniform texture |

| Production Scale | Small batch, artisanal | Large scale, industrial |

| Environmental Impact | Higher water and chemical use, waste concerns | More controlled chemical use, efficient water management |

| Cost | Lower equipment cost, higher labor cost | Higher initial investment, lower operational cost |

Introduction to Leather Tanning Methods

Pitt tanning and drum tanning are two primary leather tanning methods used to preserve animal hides and improve their durability. Pitt tanning involves immersing hides in natural tannin-rich solutions within pits, resulting in a slower process that produces supple, high-quality leather often used for traditional or artisanal goods. Drum tanning utilizes mechanical drums to agitate hides with tanning agents, accelerating the process and enabling uniform penetration, making it ideal for large-scale industrial leather production.

What is Pitt Tanning?

Pitt tanning is a traditional leather tanning method where animal hides are soaked in natural tannins within pits dug into the ground, allowing deep penetration of tanning agents over an extended period. This process typically uses vegetable tannins derived from tree bark, resulting in leather known for its durability, flexibility, and distinct natural aroma. Compared to drum tanning, Pitt tanning produces thicker, more resilient leather with a unique handmade quality favored in artisanal and heritage leather goods.

What is Drum Tanning?

Drum tanning is a leather processing method where hides are placed in large rotating drums filled with tanning agents, ensuring even exposure and uniform absorption. This technique accelerates tanning by continuously agitating the hides, producing supple and consistent leather suitable for mass production. Compared to pit tanning, drum tanning offers greater control over chemical penetration and faster processing times.

Key Differences Between Pitt and Drum Tanning

Pitt tanning involves thoroughly soaking hides in a pit filled with tanning solution, allowing deep penetration over several weeks, while drum tanning uses a rotating drum to agitate hides continuously, speeding up the tanning process in days. The key differences between Pitt and drum tanning include processing time, with Pitt tanning being much slower but offering superior softness and pliability, as well as scale and automation, where drum tanning suits large-scale industrial production with consistent results. Your choice between these methods will impact leather texture, production efficiency, and cost considerations.

Tanning Process: Step-by-Step Comparison

Pitt tanning uses natural tannins from tree bark in a slow, water-based process where hides are soaked for several weeks to achieve deep penetration and durable leather with a unique aroma and feel. Drum tanning employs mechanical drums that continuously rotate hides in tanning solutions, significantly speeding up the process to days rather than weeks, producing consistent and uniform leather quality. Both methods involve soaking, tanning, drying, and finishing steps, but Pitt tanning emphasizes natural materials and longer duration while drum tanning focuses on efficiency and scalability.

Leather Quality: Pitt Tanning vs Drum Tanning

Pitt tanning produces leather known for its unique consistency, enhanced fiber alignment, and durability due to prolonged exposure to tannins in pits, resulting in a natural, breathable texture. Drum tanning involves continuous agitation in rotating drums, yielding uniformly tanned leather with a smoother and more pliable finish ideal for high-quality garments and accessories. Your choice between Pitt and drum tanning affects leather quality significantly, balancing traditional craftsmanship with modern efficiency.

Durability and Longevity of Tanned Leather

Drum tanning produces leather with uniform thickness and enhanced fiber alignment, resulting in superior durability and longer lifespan compared to pitt tanning. Pitt tanning often yields softer leather but can exhibit less resistance to wear and environmental stress over time. The mechanical action in drum tanning promotes deeper tannin penetration, significantly improving the leather's longevity and structural integrity.

Environmental Impact: Pitt vs Drum Tanning

Pitt tanning uses natural pits or vats that allow for lower water consumption and reduced chemical runoff compared to drum tanning, which often involves mechanical agitation leading to higher energy use and more effluent discharge. Drum tanning, while faster, typically relies on synthetic chemicals and larger volumes of water, increasing the environmental footprint through wastewater contaminants and greenhouse gas emissions. Pitt tanning's traditional approach aligns better with sustainable practices by minimizing pollution and conserving resources, making it more eco-friendly in leather processing.

Applications and Uses for Each Tanning Method

Pitt tanning is ideal for producing thick, durable leather used in industrial applications, heavy-duty gloves, and saddlery due to its long soaking process that enhances strength and water resistance. Drum tanning accelerates leather production, making it suitable for mass-produced footwear, fashion accessories, and upholstery where consistent texture and pliability are essential. Your choice between these methods depends on whether you prioritize durability and toughness or efficiency and uniformity in the final leather product.

Which Tanning Method is Best for Your Needs?

Pitt tanning offers a softer, more flexible leather ideal for products requiring excellent suppleness, such as fashion accessories and garments, while drum tanning produces tougher, more durable leather suited for heavy-duty items like footwear and upholstery. Selecting the best tanning method depends on the desired leather characteristics, usage conditions, and production scale, with Pitt tanning preferred for high-quality, breathable leathers and drum tanning favored for efficiency and uniformity in large batches. Understanding the distinctions in texture, durability, and process speed helps buyers and manufacturers match the tanning method to specific product requirements.

Pitt tanning vs drum tanning Infographic

libmatt.com

libmatt.com