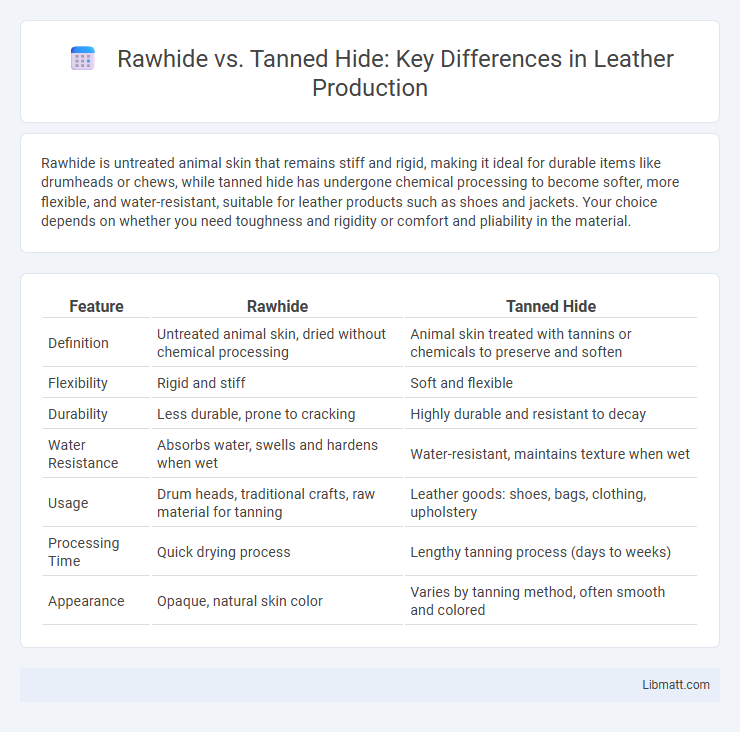

Rawhide is untreated animal skin that remains stiff and rigid, making it ideal for durable items like drumheads or chews, while tanned hide has undergone chemical processing to become softer, more flexible, and water-resistant, suitable for leather products such as shoes and jackets. Your choice depends on whether you need toughness and rigidity or comfort and pliability in the material.

Table of Comparison

| Feature | Rawhide | Tanned Hide |

|---|---|---|

| Definition | Untreated animal skin, dried without chemical processing | Animal skin treated with tannins or chemicals to preserve and soften |

| Flexibility | Rigid and stiff | Soft and flexible |

| Durability | Less durable, prone to cracking | Highly durable and resistant to decay |

| Water Resistance | Absorbs water, swells and hardens when wet | Water-resistant, maintains texture when wet |

| Usage | Drum heads, traditional crafts, raw material for tanning | Leather goods: shoes, bags, clothing, upholstery |

| Processing Time | Quick drying process | Lengthy tanning process (days to weeks) |

| Appearance | Opaque, natural skin color | Varies by tanning method, often smooth and colored |

Introduction: Rawhide and Tanned Hide Defined

Rawhide is untreated animal skin that is dried and stiff, preserving its natural texture without chemical processing. Tanned hide undergoes a chemical treatment process called tanning, which stabilizes the skin, making it softer, more durable, and resistant to decomposition. The key distinction lies in rawhide's rigidity and untreated nature versus tanned hide's enhanced flexibility and longevity through chemical preservation.

The Process: How Rawhide is Made

Rawhide is made by soaking animal hides, typically cowhide, in water to remove hair and flesh before stretching and drying them without tanning. Unlike tanned hide, rawhide undergoes no chemical treatment to stabilize the material, resulting in a harder, less flexible product. This drying process preserves the hide's natural state, making it ideal for uses such as drumheads, weapon handles, and traditional crafts.

The Tanning Process: Transforming Hide Into Leather

The tanning process chemically alters rawhide by removing moisture and stabilizing collagen fibers, converting it into durable, flexible leather suitable for various applications. Rawhide remains untreated and retains its rigidity and susceptibility to decomposition, whereas tanned hide undergoes treatments with tanning agents like chromium or vegetable tannins to achieve enhanced resistance to water, bacteria, and wear. This transformation stabilizes the protein structure, increasing the material's longevity and usability in products such as shoes, bags, and upholstery.

Key Differences in Texture and Flexibility

Rawhide features a stiff, rough texture due to its untreated fibrous structure, making it less flexible and more rigid than tanned hide. Tanned hide undergoes chemical processes that soften the material, resulting in a smoother surface and significantly increased flexibility suited for wearable items. Understanding these key differences helps you choose the right leather type for durability or comfort in your projects.

Durability and Longevity Comparison

Rawhide offers rigidity and a rustic appearance but is less flexible and more prone to cracking over time compared to tanned hide. Tanned hide undergoes chemical treatments that enhance its durability, making it resistant to moisture, decay, and wear, which significantly extends its lifespan. Choosing tanned hide for your leather goods ensures greater longevity and better performance in daily use.

Common Uses of Rawhide Products

Rawhide is commonly used in the production of durable dog chews, drum heads, and traditional crafts due to its toughness and rigidity. It remains stiff and hard when dry, making it ideal for items that require structural integrity, such as lacing for saddles and bindings. Rawhide products are favored in applications where pliability is less important than toughness and resistance to wear.

Popular Applications of Tanned Hide

Tanned hide is widely used in the production of durable leather goods such as boots, belts, and wallets, valued for its flexibility and resistance to wear. Furniture upholstery and automotive interiors also benefit from the softness and longevity provided by tanned leather. You will find tanned hide ideal for crafting high-quality accessories that require both robustness and aesthetic appeal.

Environmental and Ethical Considerations

Rawhide production involves minimal chemical processing, reducing environmental pollution compared to heavily tanned hides, which often use chromium and other toxic substances harmful to ecosystems. Ethically, rawhide tends to be sourced directly from slaughterhouses without additional chemicals, supporting more sustainable practices, whereas conventional tanning industries pose significant health risks to workers due to chemical exposure. Choosing rawhide over tanned hide aligns with eco-conscious consumer values by minimizing hazardous waste and promoting safer, less industrialized sourcing methods.

Maintenance and Care: Rawhide vs. Tanned Hide

Rawhide requires careful maintenance to prevent cracking and mold, needing occasional conditioning with oils or waxes to maintain flexibility and moisture balance. Tanned hide, treated through chemical or vegetable tanning processes, is more resistant to water damage and requires less frequent conditioning, often benefiting from leather-specific cleaners and conditioners to preserve softness and durability. Proper storage in a cool, dry place is critical for both materials to extend their lifespan and maintain structural integrity.

Choosing the Right Hide for Your Project

Rawhide offers unmatched stiffness and durability, making it ideal for projects requiring firm, rigid materials like drum heads or traditional laces. Tanned hide provides flexibility and softness, preferred for crafting comfortable leather goods such as wallets, gloves, or footwear. Understanding these distinct properties helps you select the perfect hide, ensuring your project meets both aesthetic and functional needs.

Rawhide vs tanned hide Infographic

libmatt.com

libmatt.com