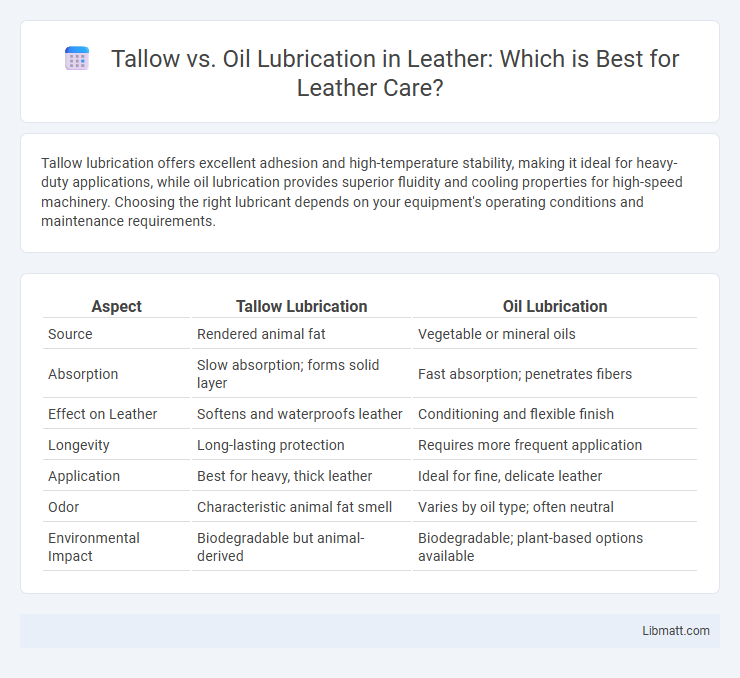

Tallow lubrication offers excellent adhesion and high-temperature stability, making it ideal for heavy-duty applications, while oil lubrication provides superior fluidity and cooling properties for high-speed machinery. Choosing the right lubricant depends on your equipment's operating conditions and maintenance requirements.

Table of Comparison

| Aspect | Tallow Lubrication | Oil Lubrication |

|---|---|---|

| Source | Rendered animal fat | Vegetable or mineral oils |

| Absorption | Slow absorption; forms solid layer | Fast absorption; penetrates fibers |

| Effect on Leather | Softens and waterproofs leather | Conditioning and flexible finish |

| Longevity | Long-lasting protection | Requires more frequent application |

| Application | Best for heavy, thick leather | Ideal for fine, delicate leather |

| Odor | Characteristic animal fat smell | Varies by oil type; often neutral |

| Environmental Impact | Biodegradable but animal-derived | Biodegradable; plant-based options available |

Introduction to Tallow and Oil Lubrication

Tallow lubrication uses animal fat, primarily rendered from beef or mutton, offering biodegradable and cost-effective properties in machinery maintenance. Oil lubrication, derived from mineral or synthetic oils, provides superior temperature stability and longer-lasting film strength for high-performance applications. Understanding the differences helps you choose the optimal lubricant for your equipment's efficiency and longevity.

Historical Use of Tallow in Lubrication

Tallow has been historically used as a primary lubricant due to its natural availability and effective water-repellent properties, particularly in early industrial machinery and blacksmithing. Unlike oils derived from petroleum or plants, tallow provided a stable, biodegradable alternative that resisted oxidation and maintained viscosity under high temperatures. Its widespread use declined with the advent of synthetic and mineral oils, which offered superior performance and longer service intervals in modern lubrication applications.

Types of Oils Used for Lubrication

Types of oils used for lubrication vary widely, including mineral oils derived from crude oil, synthetic oils engineered for specific performance characteristics, and vegetable oils such as rapeseed or castor oil. Mineral oils dominate industrial applications due to affordability and wide availability, while synthetic oils provide superior thermal stability and oxidation resistance, enhancing machinery lifespan. Vegetable-based oils offer biodegradable and eco-friendly alternatives, especially in applications requiring low toxicity and environmental impact.

Chemical Composition: Tallow vs Oil

Tallow primarily consists of triglycerides derived from animal fats, containing saturated and monounsaturated fatty acids that provide excellent film strength and lubricity at elevated temperatures. In contrast, oil lubrication typically involves mineral or synthetic oils composed of hydrocarbons with varying chain lengths and structures, offering better viscosity control and oxidative stability. The chemical composition difference influences their thermal stability, biodegradability, and compatibility with metal surfaces in lubrication applications.

Lubrication Performance Comparison

Tallow lubrication provides excellent high-pressure film strength and adheres well to metal surfaces, reducing wear in heavy machinery applications. Mineral oil lubrication offers superior low-temperature fluidity and better thermal stability, enhancing performance in engine components exposed to varying temperatures. The choice between tallow and oil depends on operating conditions, with tallow excelling in load-bearing scenarios and oil preferred for its consistent flow and oxidation resistance.

Environmental Impact and Sustainability

Tallow lubrication, derived from animal fats, is biodegradable and renewable, offering a lower environmental footprint compared to synthetic oil lubricants that often rely on petrochemicals. Oil lubrication, especially mineral-based oils, can contribute to soil and water pollution due to toxic additives and slow degradation rates. Sustainable lubrication practices prioritize biodegradable tallow or vegetable-based oils to reduce ecosystem harm and promote resource renewability.

Cost Efficiency: Tallow vs Oil

Tallow offers a cost-efficient alternative to oil lubrication due to its lower raw material and production expenses, especially in industries with high-volume consumption such as leather processing and metalwork. Oil lubrication generally incurs higher costs linked to extraction, refining, and synthetic additives, which contribute to enhanced performance but increase overall expenditure. Evaluating lifecycle costs, including maintenance frequency and environmental impact, reveals tallow's advantage in reducing operational expenses compared to traditional oil-based lubricants.

Application Suitability for Tallow and Oil

Tallow lubrication excels in applications requiring biodegradable and renewable grease, often used in heavy machinery, agriculture, and traditional industrial equipment due to its high lubricity and thermal stability. Oil lubrication is preferred for high-speed and precision machinery where lower viscosity and better heat dissipation are critical, commonly found in automotive engines, turbines, and hydraulic systems. Your choice depends on environmental conditions and machinery requirements, with tallow suited for robust, heavy-load scenarios and oil ideal for delicate, high-performance applications.

Maintenance and Longevity Factors

Tallow lubrication requires more frequent inspection and reapplication due to its tendency to oxidize and harden over time, potentially causing buildup that demands thorough cleaning. Oil lubrication offers superior maintenance ease with longer-lasting fluidity, reducing friction and wear, which enhances the longevity of machinery components significantly. Your choice between tallow and oil lubrication impacts maintenance schedules and overall equipment lifespan, with oil typically providing more consistent protection under varied operating conditions.

Future Trends in Lubrication Technologies

Emerging lubrication technologies emphasize bio-based and sustainable alternatives, with tallow gaining prominence due to its biodegradability and renewable sourcing compared to conventional oils. Advances in ultra-low friction additives and nano-lubricants are pushing performance boundaries, where tailored molecular structures in tallow-based lubricants enhance thermal stability and wear resistance. Future trends also include hybrid formulations combining tallow with synthetic oils to optimize environmental impact while maintaining superior mechanical properties for industrial and automotive applications.

Tallow vs oil lubrication Infographic

libmatt.com

libmatt.com