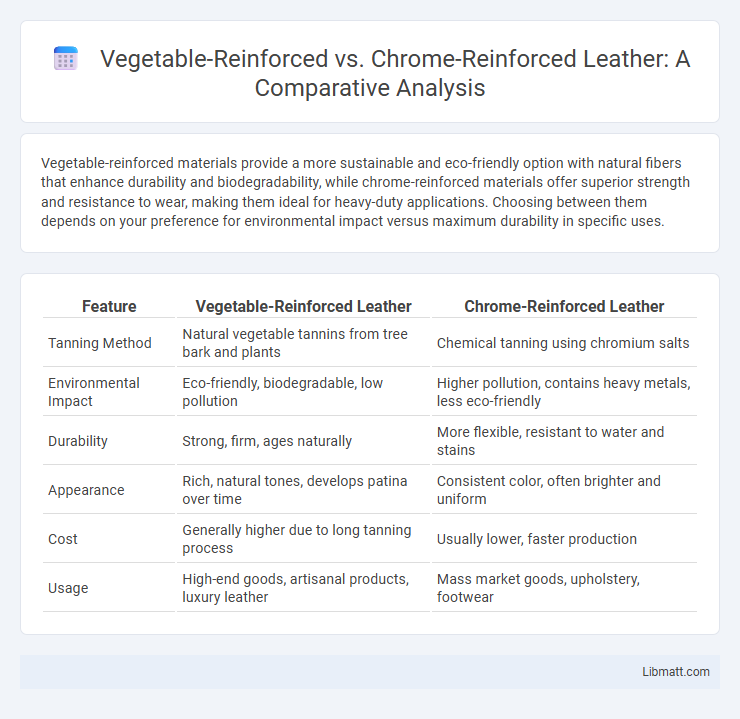

Vegetable-reinforced materials provide a more sustainable and eco-friendly option with natural fibers that enhance durability and biodegradability, while chrome-reinforced materials offer superior strength and resistance to wear, making them ideal for heavy-duty applications. Choosing between them depends on your preference for environmental impact versus maximum durability in specific uses.

Table of Comparison

| Feature | Vegetable-Reinforced Leather | Chrome-Reinforced Leather |

|---|---|---|

| Tanning Method | Natural vegetable tannins from tree bark and plants | Chemical tanning using chromium salts |

| Environmental Impact | Eco-friendly, biodegradable, low pollution | Higher pollution, contains heavy metals, less eco-friendly |

| Durability | Strong, firm, ages naturally | More flexible, resistant to water and stains |

| Appearance | Rich, natural tones, develops patina over time | Consistent color, often brighter and uniform |

| Cost | Generally higher due to long tanning process | Usually lower, faster production |

| Usage | High-end goods, artisanal products, luxury leather | Mass market goods, upholstery, footwear |

Introduction to Reinforcement Methods

Vegetable-reinforced leather uses natural tannins derived from plant sources, offering eco-friendly durability and a firm texture ideal for traditional craftsmanship. Chrome-reinforced leather undergoes a chemical tanning process using chromium salts, resulting in more flexible, water-resistant, and quicker-to-produce materials suited for mass manufacturing. Understanding these reinforcement methods helps you choose leather products that balance sustainability, durability, and performance based on your specific needs.

Overview of Vegetable-Reinforced Materials

Vegetable-reinforced materials, derived from natural fibers such as flax, hemp, jute, and sisal, offer sustainable reinforcement options with low environmental impact and high biodegradability. These fibers exhibit good tensile strength, lightweight properties, and excellent acoustic insulation, making them ideal for automotive, construction, and packaging industries. Compared to chrome-reinforced materials, vegetable reinforcements reduce reliance on toxic chemicals while promoting renewable resource use and enhanced eco-friendly composite performance.

Basics of Chrome-Reinforced Composites

Chrome-reinforced composites consist of fibers embedded in a chromium oxide matrix, offering superior hardness and wear resistance compared to vegetable-reinforced composites. The chromium reinforcement enhances thermal stability and corrosion resistance, making these composites ideal for high-performance industrial applications. If your project demands maximum durability and long-term structural integrity, chrome-reinforced materials provide a significant advantage.

Key Differences: Vegetable vs. Chrome Reinforcement

Vegetable-reinforced tanning uses natural tannins from plant sources, resulting in a firmer, more breathable leather with a distinctive earthy aroma, while chrome-reinforced tanning employs chromium salts to produce softer, more water-resistant leather with enhanced color retention. Vegetable-tanned leather develops a rich patina over time, making it ideal for artisanal goods, whereas chrome-tanned leather offers durability and flexibility suitable for mass-produced products like footwear and upholstery. Your choice between vegetable and chrome reinforcement should align with the desired leather characteristics and product application.

Mechanical Strength Comparison

Vegetable-reinforced materials typically offer moderate mechanical strength through natural fibers like flax or hemp, which provide flexibility and impact resistance but may degrade faster under stress. Chrome-reinforced composites, incorporating chromium particles or plating, deliver significantly higher tensile strength and durability, ideal for heavy-load applications and extended wear resistance. Your choice should weigh the mechanical demands of the project against environmental considerations, as chrome reinforcement excels in strength while vegetable alternatives favor sustainability.

Environmental Impact Analysis

Vegetable-reinforced leather demonstrates a significantly lower environmental impact compared to chrome-reinforced leather due to its natural tanning agents derived from sustainable plant sources, reducing toxic chemical discharge and water pollution. Chrome tanning processes release hazardous chromium compounds, leading to soil and groundwater contamination, posing serious ecological and human health risks. Choosing vegetable-reinforced leather supports a safer and more eco-friendly manufacturing cycle, aligning with your commitment to sustainability and environmental responsibility.

Cost Efficiency and Economic Considerations

Vegetable-reinforced materials typically offer greater cost efficiency due to lower raw material expenses and sustainable sourcing, making them an economical choice for eco-conscious businesses. Chrome-reinforced options, while generally pricier due to complex processing and material costs, provide enhanced durability that can reduce long-term maintenance and replacement expenses. Your decision should weigh immediate budget constraints against potential lifecycle savings and environmental impact.

Health and Safety Implications

Vegetable-reinforced materials, derived from natural plant fibers, offer superior biodegradability and reduced chemical exposure compared to chrome-reinforced alternatives, which often contain toxic chromium compounds linked to respiratory issues and skin irritation. Your choice of vegetable-reinforced products minimizes the risk of harmful environmental impact and potential carcinogenic effects associated with chromium. Ensuring safety in manufacturing and disposal phases, vegetable reinforcements promote healthier working conditions and eco-friendly practices.

Industry Applications and Suitability

Vegetable-reinforced materials offer superior biodegradability and are widely used in eco-friendly packaging, cosmetics, and food industry applications where sustainability and safety are paramount. Chrome-reinforced materials exhibit exceptional durability and corrosion resistance, making them ideal for heavy-duty industrial applications such as automotive parts, machinery, and chemical processing equipment. Selection between vegetable-reinforced and chrome-reinforced materials depends on the specific industry requirements for environmental impact, mechanical strength, and chemical exposure.

Future Trends in Reinforcement Technologies

Future trends in reinforcement technologies indicate a strong shift towards sustainable materials, with vegetable-reinforced composites gaining traction due to their biodegradability and lower carbon footprint compared to chrome-reinforced alternatives. Innovations in bio-based resins and natural fiber treatments enhance the mechanical properties and durability of vegetable-reinforced composites, making them competitive in automotive and construction industries. Advances in nano-reinforcement and hybrid layering techniques are expected to improve strength-to-weight ratios and corrosion resistance, positioning vegetable-reinforced materials as a key sustainable alternative to traditional chrome-reinforced composites.

Vegetable-reinforced vs chrome-reinforced Infographic

libmatt.com

libmatt.com