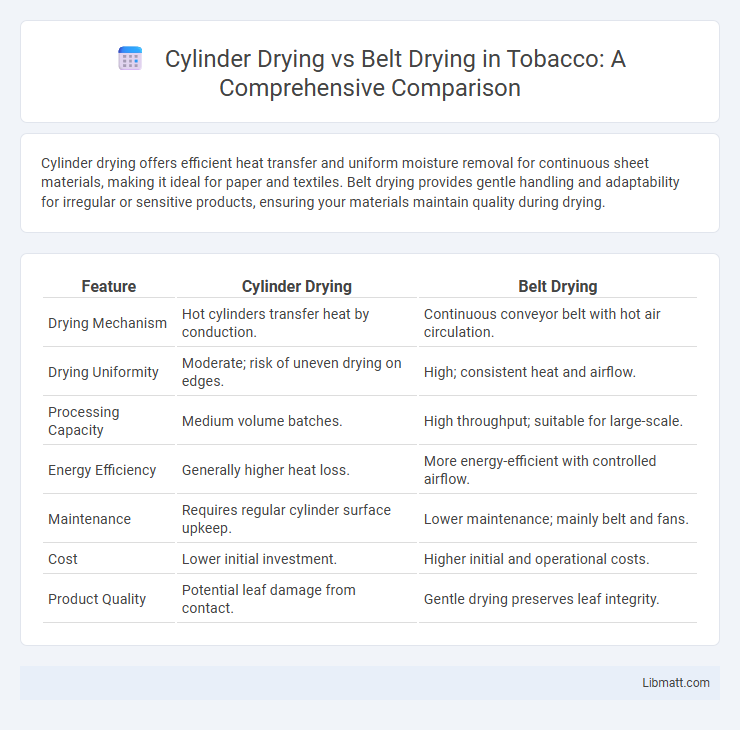

Cylinder drying offers efficient heat transfer and uniform moisture removal for continuous sheet materials, making it ideal for paper and textiles. Belt drying provides gentle handling and adaptability for irregular or sensitive products, ensuring your materials maintain quality during drying.

Table of Comparison

| Feature | Cylinder Drying | Belt Drying |

|---|---|---|

| Drying Mechanism | Hot cylinders transfer heat by conduction. | Continuous conveyor belt with hot air circulation. |

| Drying Uniformity | Moderate; risk of uneven drying on edges. | High; consistent heat and airflow. |

| Processing Capacity | Medium volume batches. | High throughput; suitable for large-scale. |

| Energy Efficiency | Generally higher heat loss. | More energy-efficient with controlled airflow. |

| Maintenance | Requires regular cylinder surface upkeep. | Lower maintenance; mainly belt and fans. |

| Cost | Lower initial investment. | Higher initial and operational costs. |

| Product Quality | Potential leaf damage from contact. | Gentle drying preserves leaf integrity. |

Introduction to Industrial Drying Methods

Cylinder drying utilizes heated rotating drums to remove moisture from materials, offering high heat transfer efficiency ideal for continuous web processing in industries like paper and textiles. Belt drying employs a conveyor belt to pass materials through a drying chamber, providing gentle, uniform drying suited for fragile or granular substances. Your choice between cylinder drying and belt drying depends on factors such as product sensitivity, drying speed, and energy consumption requirements.

Overview of Cylinder Drying Technology

Cylinder drying technology utilizes large, heated rotating cylinders to remove moisture from materials by direct contact, offering efficient thermal energy transfer and rapid drying rates. This method excels in drying paper, textiles, and food products, providing uniform drying with controlled temperature and pressure settings that minimize product damage. Compared to belt drying, cylinder drying ensures higher throughput and energy efficiency while maintaining consistent product quality through precise moisture control.

Fundamentals of Belt Drying Systems

Belt drying systems use a continuous porous belt to transport wet material through controlled heat and airflow, efficiently removing moisture while preserving product integrity. You can customize parameters like belt speed, temperature, and air velocity to optimize drying for various materials, ensuring consistent moisture content and energy efficiency. Compared to cylinder drying, belt drying offers greater flexibility and is ideal for fragile or heat-sensitive products due to its gentle drying mechanism.

Key Differences Between Cylinder and Belt Drying

Cylinder drying uses steam-heated rotating drums to evaporate moisture, offering rapid drying for paper and textiles with consistent contact and pressure. Belt drying employs conveyors where materials pass through heated zones, suitable for fragile items requiring gentle handling and uniform temperature distribution. Cylinder drying typically achieves higher throughput and better mechanical strength in products, while belt drying allows more control over drying conditions and is preferred for heat-sensitive substances.

Efficiency and Energy Consumption Comparison

Cylinder drying offers higher thermal efficiency with rapid heat transfer through direct contact, resulting in lower energy consumption for moisture removal compared to belt drying. Belt drying typically consumes more energy due to indirect heat transfer and longer drying times, though it provides gentle handling for heat-sensitive materials. Your choice depends on balancing energy costs with product sensitivity and drying speed requirements.

Product Quality and Moisture Uniformity

Cylinder drying offers superior product quality by providing gentle heat transfer, minimizing thermal damage and preserving the material's integrity. Moisture uniformity is enhanced in cylinder drying due to consistent contact with heated surfaces, resulting in even drying throughout the product. Belt drying can experience uneven moisture distribution because of variable airflow and product thickness differences on the moving belt.

Applications: Which Materials Suit Each Method?

Cylinder drying excels in processing materials like paper, textiles, and pulp due to its ability to handle continuous sheet forms with uniform moisture removal. Belt drying is ideal for granular or particulate materials such as food products, chemicals, and pharmaceuticals, where even drying of loose or small items is critical. Your choice depends on the material's form and moisture content, with cylinder drying suited for flat, continuous webs and belt drying for loose, bulk solids.

Maintenance and Operational Considerations

Cylinder drying requires regular inspection and cleaning to prevent fouling and corrosion, with maintenance focusing on drum surface condition and steam system integrity. Belt drying involves more complex upkeep due to the conveyor belt's wear, tension adjustments, and potential belt replacement costs. Your operational efficiency depends on selecting the method best aligned with available maintenance resources and process requirements.

Environmental Impact and Sustainability

Cylinder drying consumes more energy due to its reliance on steam and heat transfer, leading to higher greenhouse gas emissions compared to belt drying, which often uses lower temperatures and can integrate waste heat recovery. Belt drying typically offers better environmental sustainability by reducing energy consumption and enabling controlled airflow, minimizing pollutant emissions and water usage. Your choice of drying method can significantly influence your facility's carbon footprint and commitment to sustainable operations.

Cost Analysis: Cylinder Drying vs Belt Drying

Cylinder drying typically incurs higher initial costs due to large equipment and installation requirements, but offers lower operational expenses through efficient heat transfer and reduced energy consumption. Belt drying involves lower startup investment but may result in higher ongoing costs because of slower drying speeds and increased maintenance needs related to belt wear and system complexity. Your choice between cylinder and belt drying should consider not only upfront expenses but also long-term energy efficiency and maintenance implications for optimal cost management.

Cylinder drying vs belt drying Infographic

libmatt.com

libmatt.com