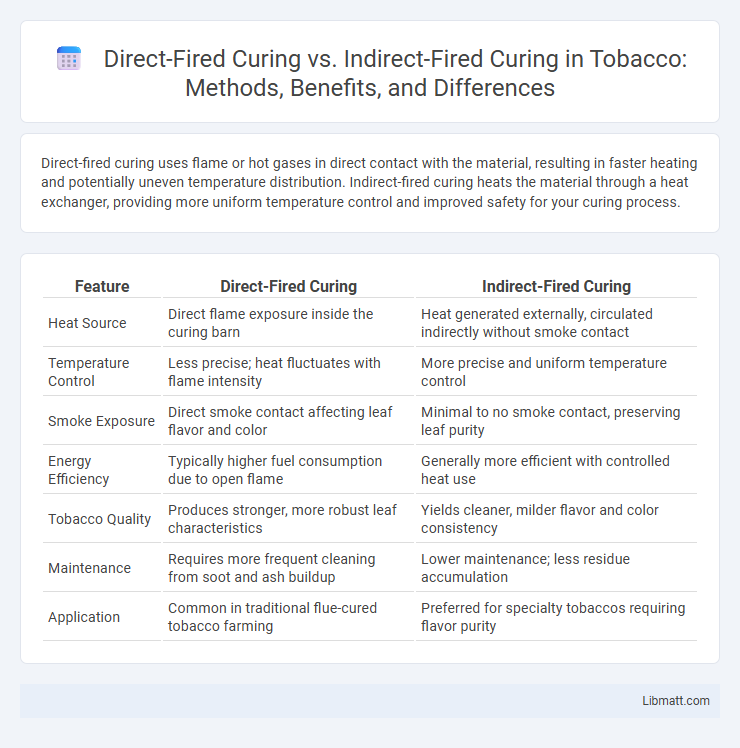

Direct-fired curing uses flame or hot gases in direct contact with the material, resulting in faster heating and potentially uneven temperature distribution. Indirect-fired curing heats the material through a heat exchanger, providing more uniform temperature control and improved safety for your curing process.

Table of Comparison

| Feature | Direct-Fired Curing | Indirect-Fired Curing |

|---|---|---|

| Heat Source | Direct flame exposure inside the curing barn | Heat generated externally, circulated indirectly without smoke contact |

| Temperature Control | Less precise; heat fluctuates with flame intensity | More precise and uniform temperature control |

| Smoke Exposure | Direct smoke contact affecting leaf flavor and color | Minimal to no smoke contact, preserving leaf purity |

| Energy Efficiency | Typically higher fuel consumption due to open flame | Generally more efficient with controlled heat use |

| Tobacco Quality | Produces stronger, more robust leaf characteristics | Yields cleaner, milder flavor and color consistency |

| Maintenance | Requires more frequent cleaning from soot and ash buildup | Lower maintenance; less residue accumulation |

| Application | Common in traditional flue-cured tobacco farming | Preferred for specialty tobaccos requiring flavor purity |

Introduction to Curing Methods in Industrial Applications

Direct-fired curing involves applying heat directly to the material using open flames or combustion gases, offering rapid temperature rise and energy efficiency in industrial applications. Indirect-fired curing uses heat exchangers or heated air to transfer energy without direct contact with combustion products, ensuring cleaner and more controlled curing environments. Choosing the right method impacts product quality, operational costs, and environmental compliance, which directly affects your manufacturing process efficiency.

Understanding Direct-Fired Curing: Principles and Process

Direct-fired curing involves the combustion flame coming into direct contact with the material, efficiently transferring heat through convection and radiation for rapid curing. This process relies on precise control of temperature and airflow to prevent surface damage while ensuring uniform heat distribution. Understanding these principles helps you optimize curing cycles, improve product quality, and reduce energy consumption in applications like powder coating and composite manufacturing.

Exploring Indirect-Fired Curing: How It Works

Indirect-fired curing uses a heat exchanger to transfer heat from a combustion source to the curing environment without direct contact between the flame and the material. This method provides more uniform temperature control and reduces contamination risks compared to direct-fired curing. Your processes benefit from improved product quality and energy efficiency due to precise heat management inherent in indirect-fired systems.

Key Differences Between Direct-Fired and Indirect-Fired Curing

Direct-fired curing involves combustion gases coming into direct contact with the product, providing rapid and intense heat transfer, which is ideal for applications requiring quick drying times. Indirect-fired curing uses a heat exchanger to separate combustion gases from the product, offering more precise temperature control and reducing the risk of contamination. Your choice between these methods depends on the specific process requirements, such as speed versus temperature uniformity and product sensitivity.

Efficiency and Energy Consumption Comparison

Direct-fired curing systems typically achieve higher thermal efficiency by transferring heat directly to the product, resulting in faster curing times and reduced fuel consumption. Indirect-fired curing relies on a heat exchanger to transfer heat, which can cause energy losses and lower overall system efficiency despite providing cleaner combustion emissions. Studies indicate that direct-fired systems can reduce energy consumption by up to 20% compared to indirect-fired systems in industrial curing applications.

Impact on Product Quality and Uniformity

Direct-fired curing exposes products to combustion gases, which can introduce contaminants and cause uneven temperature distribution, potentially compromising product quality and uniformity. Indirect-fired curing uses a heat exchanger to transfer heat without direct contact with combustion gases, resulting in more consistent temperatures and improved product surface finish. Your choice of curing method directly affects the consistency and integrity of the final product, influencing both yield and customer satisfaction.

Safety Considerations for Each Curing Method

Direct-fired curing poses increased risks of flame exposure and combustion byproducts contacting the material being cured, requiring strict ventilation and fire safety controls to prevent hazardous fumes and ignition. Indirect-fired curing utilizes a heat exchanger to separate combustion gases from the curing chamber, significantly reducing the risk of contamination and improving operator safety by minimizing exposure to combustion-related hazards. Both methods demand rigorous monitoring of temperature and airflow to ensure safe operation and to prevent accidents linked to overheating or gas leaks.

Environmental Factors: Emissions and Air Quality

Direct-fired curing systems emit combustion gases directly into the curing chamber, potentially increasing volatile organic compounds (VOCs) and particulate emissions, which can negatively impact air quality. Indirect-fired curing uses a heat exchanger to separate combustion gases from the curing environment, significantly reducing pollutants released into the atmosphere and improving compliance with environmental regulations. Optimizing your process with indirect-fired curing can enhance air quality by minimizing emissions and supporting sustainable manufacturing practices.

Cost Analysis: Installation and Operating Expenses

Direct-fired curing systems generally have lower installation costs due to simpler equipment and fewer components compared to indirect-fired systems, which require additional heat exchangers and ducting. Operating expenses for direct-fired curing tend to be higher because combustion gases come into direct contact with the product, potentially increasing maintenance and energy consumption to maintain consistent temperatures. Indirect-fired curing has higher upfront installation costs but offers reduced operating expenses through improved energy efficiency and lower maintenance needs by isolating combustion products from the curing environment.

Choosing the Right Curing Method for Your Application

Choosing the right curing method depends on factors such as temperature control, energy efficiency, and application sensitivity. Direct-fired curing offers rapid heating and higher temperatures suitable for industrial processes requiring quick cycles, while indirect-fired curing provides more uniform heat distribution and is ideal for materials sensitive to combustion byproducts. Analyzing specific application requirements, including material type and production speed, ensures optimal curing performance and product quality.

Direct-fired curing vs indirect-fired curing Infographic

libmatt.com

libmatt.com