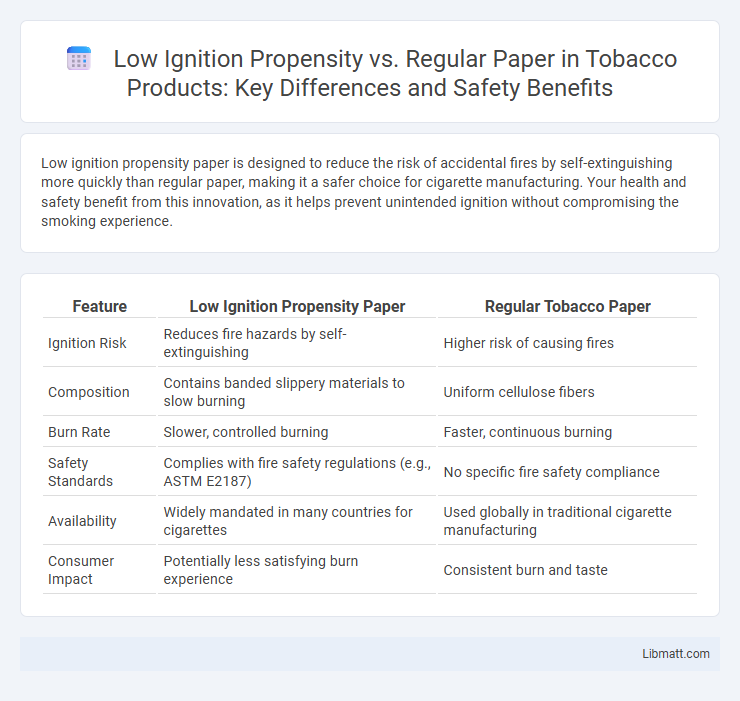

Low ignition propensity paper is designed to reduce the risk of accidental fires by self-extinguishing more quickly than regular paper, making it a safer choice for cigarette manufacturing. Your health and safety benefit from this innovation, as it helps prevent unintended ignition without compromising the smoking experience.

Table of Comparison

| Feature | Low Ignition Propensity Paper | Regular Tobacco Paper |

|---|---|---|

| Ignition Risk | Reduces fire hazards by self-extinguishing | Higher risk of causing fires |

| Composition | Contains banded slippery materials to slow burning | Uniform cellulose fibers |

| Burn Rate | Slower, controlled burning | Faster, continuous burning |

| Safety Standards | Complies with fire safety regulations (e.g., ASTM E2187) | No specific fire safety compliance |

| Availability | Widely mandated in many countries for cigarettes | Used globally in traditional cigarette manufacturing |

| Consumer Impact | Potentially less satisfying burn experience | Consistent burn and taste |

Understanding Low Ignition Propensity (LIP) Paper

Low Ignition Propensity (LIP) paper is designed to reduce the risk of fires by controlling the burning rate of cigarettes. Unlike regular paper, LIP paper contains special burn-control additives or bands that self-extinguish if the cigarette is left unattended. Understanding LIP paper helps you make informed choices about safer tobacco products that comply with fire prevention regulations.

Characteristics of Regular Paper Combustibility

Regular paper exhibits high combustibility due to its porous structure and the presence of cellulose fibers, which readily ignite when exposed to flame or heat. Unlike low ignition propensity paper, it lacks specialized additives that slow ignition, making it more prone to rapid burning and flame spread. Understanding your use of regular paper highlights the importance of fire safety measures in environments where ignition risk is critical.

How LIP Paper Reduces Fire Risks

Low Ignition Propensity (LIP) paper reduces fire risks by incorporating chemical additives that slow the burning rate of cigarettes, allowing them to self-extinguish when not actively smoked. Regular paper combusts rapidly, increasing the chance of accidental fires from unattended cigarettes. The use of LIP paper has been scientifically proven to lower ignition incidents, significantly enhancing fire safety in residential and public environments.

Key Differences Between LIP and Regular Paper

Low ignition propensity (LIP) paper is engineered to reduce the risk of cigarette-related fires by incorporating special chemical treatments and altered fiber structures that promote self-extinguishing properties. Regular paper lacks these fire-retardant modifications, making it more prone to continuous burning when a cigarette is left unattended. The key difference lies in LIP paper's ability to form narrower, slower-burning zones, significantly enhancing smoker safety compared to standard paper.

Manufacturing Process of Low Ignition Propensity Paper

The manufacturing process of low ignition propensity (LIP) paper involves incorporating specific additives and controlled fiber treatments to reduce its flammability compared to regular paper. These modifications, such as adding combustion-modifying chemicals or altering fiber density, ensure that the paper self-extinguishes more quickly when exposed to heat. Your choice of LIP paper improves fire safety by meeting stringent regulatory standards without compromising print quality.

Applications of LIP Paper in Industry

Low Ignition Propensity (LIP) paper is extensively used in the tobacco industry to reduce the risk of accidental fires caused by cigarettes. Regulatory compliance drives tobacco manufacturers to adopt LIP paper in cigarette production, improving safety standards. Beyond tobacco, LIP paper technology finds applications in packaging industries where fire-retardant materials are essential for consumer safety and product protection.

Safety Regulations and Standards for Paper Ignition

Low ignition propensity (LIP) paper is engineered to meet stringent safety regulations aimed at reducing the risk of accidental fires caused by cigarette ignition. Regulatory standards such as the U.S. Consumer Product Safety Commission's requirements mandate that LIP paper must self-extinguish more quickly than regular paper, dramatically improving fire safety. Your compliance with these regulations ensures safer product design, minimizing fire hazards associated with tobacco products.

Environmental Impact: LIP vs Regular Paper

Low ignition propensity (LIP) paper significantly reduces the risk of fires caused by smoldering cigarettes, contributing to overall environmental safety. Unlike regular paper, LIP paper incorporates additives that promote self-extinguishment, decreasing potential wildfire incidents and lowering related carbon emissions. Your choice of LIP paper supports safer environmental practices by minimizing fire hazards and conserving natural resources.

Cost Comparison: LIP Paper Versus Traditional Options

Low ignition propensity (LIP) paper typically costs 10-15% more than regular paper due to enhanced safety features and specialized manufacturing processes. The increased expense reflects investments in fire-resistant additives and quality control measures that help reduce fire risks. Your choice of LIP paper can lead to potential long-term savings by minimizing fire hazards and related liabilities, despite the slightly higher initial cost compared to traditional options.

Choosing the Right Paper for Fire Safety

Low ignition propensity (LIP) paper reduces the risk of cigarette fires by burning slower and self-extinguishing more quickly than regular paper. Fire safety regulations often require cigarettes to use LIP paper to minimize accidental fires caused by unattended smoldering. Choosing the right paper, especially LIP paper, enhances your fire safety by significantly lowering the likelihood of ignition and promoting safer smoking practices.

low ignition propensity vs regular paper Infographic

libmatt.com

libmatt.com