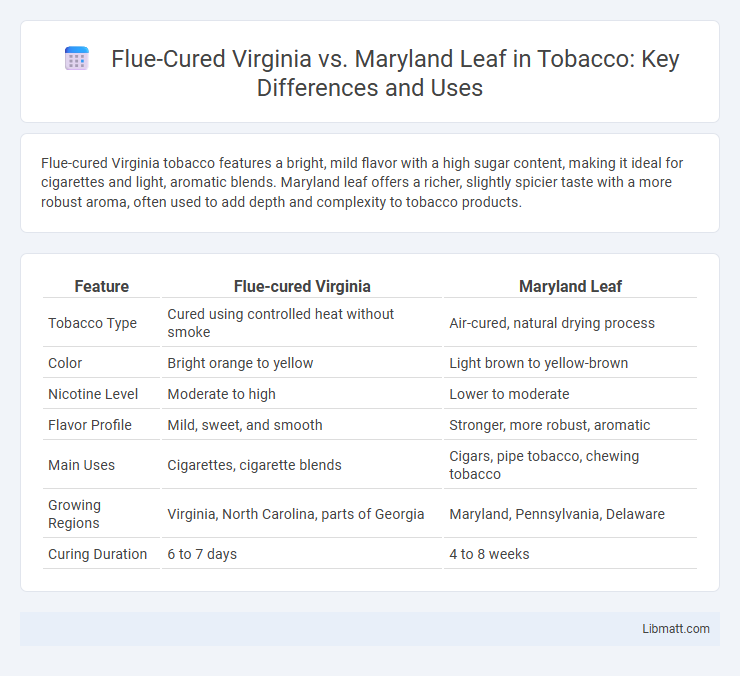

Flue-cured Virginia tobacco features a bright, mild flavor with a high sugar content, making it ideal for cigarettes and light, aromatic blends. Maryland leaf offers a richer, slightly spicier taste with a more robust aroma, often used to add depth and complexity to tobacco products.

Table of Comparison

| Feature | Flue-cured Virginia | Maryland Leaf |

|---|---|---|

| Tobacco Type | Cured using controlled heat without smoke | Air-cured, natural drying process |

| Color | Bright orange to yellow | Light brown to yellow-brown |

| Nicotine Level | Moderate to high | Lower to moderate |

| Flavor Profile | Mild, sweet, and smooth | Stronger, more robust, aromatic |

| Main Uses | Cigarettes, cigarette blends | Cigars, pipe tobacco, chewing tobacco |

| Growing Regions | Virginia, North Carolina, parts of Georgia | Maryland, Pennsylvania, Delaware |

| Curing Duration | 6 to 7 days | 4 to 8 weeks |

Introduction to Flue-Cured Virginia and Maryland Leaf

Flue-cured Virginia tobacco is renowned for its bright, yellow-golden leaves achieved through a controlled heat-curing process that enhances its mild flavor and smooth smoking qualities. Maryland leaf, although also flue-cured, tends to have a slightly darker color and a richer, more robust flavor profile due to regional soil variations and curing techniques. Both types serve distinct market preferences, with Virginia leaf favored in cigarettes for its lightness and Maryland leaf valued in pipe tobacco blends for its fuller taste.

Historical Background of Each Tobacco Variety

Flue-cured Virginia tobacco originated in the early 19th century, primarily grown in the southeastern United States, known for its bright color and mild flavor achieved through a controlled curing process with heated air. Maryland leaf tobacco, rooted in the 17th century colonial era, was traditionally air-cured and valued for its darker color and richer, fuller flavor profile, cultivated along the Chesapeake Bay region. Each variety reflects distinct regional agricultural practices and market demands that shaped their development and use in cigarette production.

Key Differences in Cultivation Methods

Flue-cured Virginia tobacco is grown using a high-temperature curing process in enclosed barns, which enhances its light, bright color and mild flavor, while Maryland leaf typically undergoes air curing in open sheds, resulting in a darker, coarser product with a stronger taste. Flue-cured Virginia requires more intensive management, including frequent irrigation and fertilization, compared to the more resilient Maryland leaf that thrives in less controlled environments. Your choice between these two tobacco types will depend on the desired flavor profile and cultivation conditions suitable for your farm.

Geographic Origins and Growing Regions

Flue-cured Virginia tobacco primarily originates from the southeastern United States, especially Virginia, North Carolina, and South Carolina, thriving in well-drained sandy loam soils and warm climates. Maryland leaf, also flue-cured, is cultivated mainly in Maryland and parts of southern Pennsylvania, benefiting from slightly cooler temperatures and richer soil compositions. Your choice between these tobaccos can be influenced by subtle differences in flavor and burning characteristics caused by their distinct geographic origins and growing conditions.

Leaf Characteristics: Color, Texture, and Aroma

Flue-cured Virginia leaf is known for its bright, golden-yellow color, smooth texture, and mild, sweet aroma, making it highly suitable for premium cigarette blends. Maryland leaf typically exhibits a darker, reddish-brown color with a coarser texture and a richer, more robust aroma that adds depth to tobacco products. Understanding these leaf characteristics helps you select the best tobacco for your desired flavor profile and quality.

Curing Processes: Flue-Curing vs. Air-Curing

Flue-cured Virginia tobacco undergoes a controlled curing process in enclosed barns with flue pipes that provide indirect heat, maintaining temperature and humidity to develop its characteristic bright, golden color and mild flavor. Maryland leaf is traditionally air-cured, hung in well-ventilated barns to dry naturally through ambient air circulation, resulting in a darker, coarser leaf with a richer, more robust taste. The differences in curing techniques significantly impact the chemical composition and combustion properties of the leaves, influencing their suitability for various tobacco products.

Flavor Profiles and Smoking Experience

Flue-cured Virginia tobacco offers a naturally sweet, mild flavor with caramel and citrus notes, ideal for smooth and mellow smoking experiences. Maryland leaf presents a richer, earthier taste with hints of spice and wood, providing deeper complexity and a more robust smoke. Your choice between these tobaccos depends on whether you prefer a lighter, subtly sweet profile or a fuller-bodied, aromatic flavor.

Usage in Cigarette and Pipe Blends

Flue-cured Virginia leaf is predominantly used in cigarette blends due to its bright, sweet flavor and high sugar content that enhances smoothness and combustion. Maryland leaf, often air-cured and more mildly flavored, is favored in pipe tobacco blends for its mildness and ability to blend well without overpowering other tobaccos. Cigarette blends leverage flue-cured Virginia for its consistent burn and sweetness, while Maryland leaf is prized for adding complexity and subtle aroma in pipe blends.

Market Demand and Commercial Importance

Flue-cured Virginia tobacco dominates global market demand due to its high-quality leaf favored by cigarette manufacturers, contributing significantly to export revenues in countries like the United States and Zimbabwe. Maryland leaf, valued for its mild flavor and thin, elastic texture, commands a niche market primarily used in cigarette blends and pipe tobacco, supporting smaller-scale commercial production. Both types hold critical economic roles, with Virginia leaf impacting large-scale tobacco industry revenue and Maryland leaf sustaining regional farming communities.

Environmental Impact and Sustainability Concerns

Flue-cured Virginia tobacco typically requires more intensive energy use for curing due to its higher temperature needs, resulting in a larger carbon footprint compared to Maryland leaf, which benefits from a milder curing process. Maryland tobacco often uses more sustainable farming practices such as reduced chemical inputs and crop rotation, minimizing soil degradation and water contamination. Your choice between these tobacco types can influence environmental sustainability by favoring less energy-intensive and more eco-friendly cultivation methods.

Flue-cured Virginia vs Maryland leaf Infographic

libmatt.com

libmatt.com