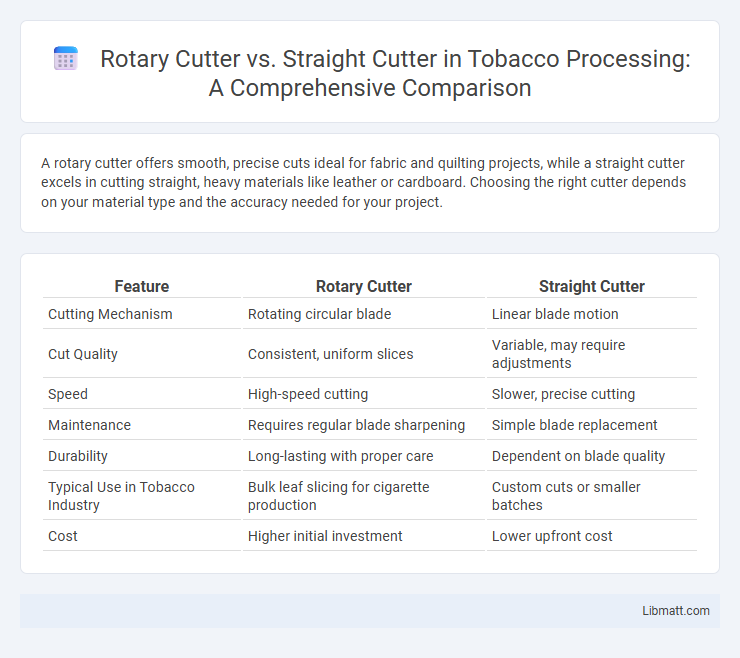

A rotary cutter offers smooth, precise cuts ideal for fabric and quilting projects, while a straight cutter excels in cutting straight, heavy materials like leather or cardboard. Choosing the right cutter depends on your material type and the accuracy needed for your project.

Table of Comparison

| Feature | Rotary Cutter | Straight Cutter |

|---|---|---|

| Cutting Mechanism | Rotating circular blade | Linear blade motion |

| Cut Quality | Consistent, uniform slices | Variable, may require adjustments |

| Speed | High-speed cutting | Slower, precise cutting |

| Maintenance | Requires regular blade sharpening | Simple blade replacement |

| Durability | Long-lasting with proper care | Dependent on blade quality |

| Typical Use in Tobacco Industry | Bulk leaf slicing for cigarette production | Custom cuts or smaller batches |

| Cost | Higher initial investment | Lower upfront cost |

Introduction to Rotary Cutters and Straight Cutters

Rotary cutters feature a circular blade designed for smooth, precise fabric cutting, ideal for quilting and detailed sewing projects. Straight cutters, typically equipped with a straight blade, excel at making long, clean cuts on materials like leather, cardboard, and textiles. Both tools offer specialized cutting methods that cater to different crafting and industrial needs, emphasizing precision and efficiency.

Design Features: Rotary Cutter vs Straight Cutter

Rotary cutters feature a circular blade that rotates smoothly, providing continuous cutting motion ideal for quilting, fabric, and paper crafts, while straight cutters use a fixed, linear blade designed for precise, straight cuts on various materials. The ergonomic design of rotary cutters often includes a comfortable handle and safety guard, enhancing control and reducing hand fatigue compared to straight cutters, which rely on a stationary blade and require more manual pressure. Materials used in rotary blades are typically high-quality steel for durability and sharpness, whereas straight cutters may incorporate replaceable blades to maintain cutting accuracy over time.

Cutting Efficiency and Precision

Rotary cutters offer superior cutting efficiency by smoothly gliding through multiple fabric layers, minimizing fraying and ensuring consistent cuts. Straight cutters provide precise, controlled cuts ideal for straight edges but may require more effort and time on thick or multiple layers. The choice between rotary and straight cutters directly impacts the accuracy and speed of fabric cutting tasks in sewing and quilting projects.

Versatility Across Materials

Rotary cutters excel in versatility across various materials, efficiently slicing through fabric, leather, and paper with smooth, continuous motion that reduces fraying. Straight cutters provide precise, clean cuts ideal for tougher or thicker materials such as cardboard or multiple fabric layers but often require additional effort and skill to maintain accuracy. Choosing between rotary and straight cutters depends on the specific material characteristics and precision requirements of the project.

Safety Considerations

Rotary cutters offer enhanced safety due to their retractable blade design, minimizing accidental cuts when not in use. Straight cutters require more cautious handling since their exposed blades increase the risk of injury during cutting and storage. To protect your fingers and maintain precise control, always use a cutting mat and keep blades sharp, regardless of the cutter type.

Maintenance and Blade Longevity

Rotary cutters require regular blade sharpening and careful handling to maintain their sharpness, as the circular blade can dull quickly with frequent use. Straight cutters, on the other hand, often have longer-lasting blades that need less frequent replacement but may require professional sharpening to maintain optimal performance. Proper maintenance of your rotary or straight cutter blades ensures precision and extends their lifespan, reducing the need for constant replacements.

Ergonomics and User Comfort

Rotary cutters feature a circular blade that glides smoothly over fabric, reducing wrist strain and enhancing precision for prolonged use. Straight cutters require more downward force and repetitive motion, which can cause hand fatigue and discomfort during extended cutting sessions. Ergonomic handles on rotary cutters are often cushioned and contoured to fit the hand better, promoting enhanced user comfort and control.

Price Comparison

Rotary cutters generally offer a higher initial price compared to straight cutters due to their precision design and versatility in cutting multiple fabric layers. Straight cutters tend to be more affordable upfront but may require more frequent blade replacements, affecting long-term costs. Your choice should consider both the immediate price and the efficiency benefits of each cutter type.

Best Applications for Each Cutter

Rotary cutters excel in cutting multiple layers of fabric simultaneously, making them ideal for quilting, pattern cutting, and detailed curves. Straight cutters provide precision for straight lines and simpler cuts, perfect for tailoring, garment construction, and trimming edges. Your choice depends on whether you need versatility with curves or accuracy on straight cuts.

Choosing the Right Cutter for Your Needs

Choosing the right cutter for your needs depends on the type of fabric and the project complexity; rotary cutters offer precision and ease for curved lines and quilting, while straight cutters excel at making long, straight cuts in thicker materials. Your decision should consider blade sharpness, handle comfort, and safety features like blade guards or automatic retracting blades for efficient and secure cutting. Evaluating these factors ensures you select a tool that enhances your crafting accuracy and comfort.

rotary cutter vs straight cutter Infographic

libmatt.com

libmatt.com