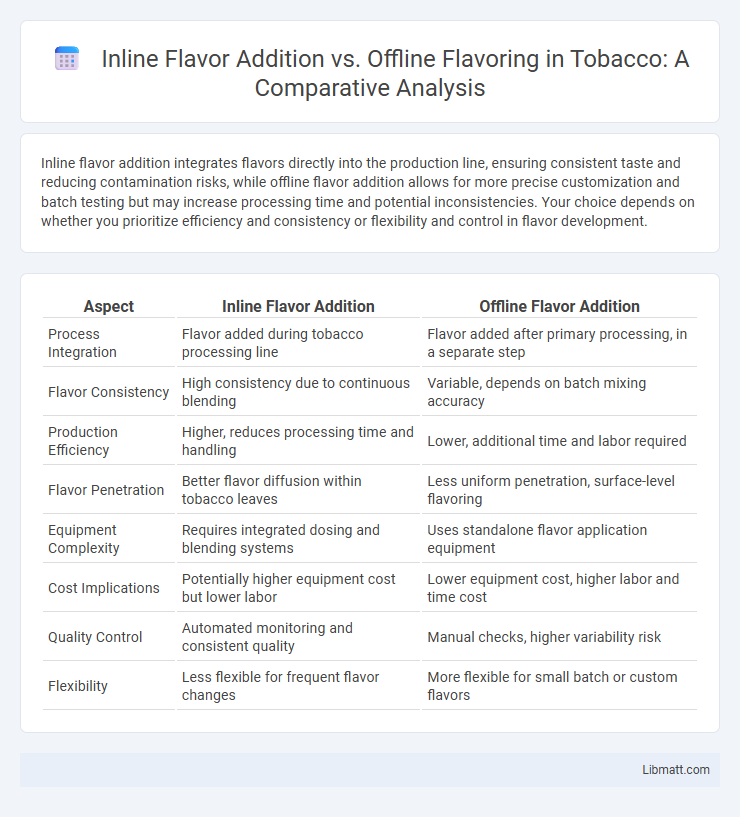

Inline flavor addition integrates flavors directly into the production line, ensuring consistent taste and reducing contamination risks, while offline flavor addition allows for more precise customization and batch testing but may increase processing time and potential inconsistencies. Your choice depends on whether you prioritize efficiency and consistency or flexibility and control in flavor development.

Table of Comparison

| Aspect | Inline Flavor Addition | Offline Flavor Addition |

|---|---|---|

| Process Integration | Flavor added during tobacco processing line | Flavor added after primary processing, in a separate step |

| Flavor Consistency | High consistency due to continuous blending | Variable, depends on batch mixing accuracy |

| Production Efficiency | Higher, reduces processing time and handling | Lower, additional time and labor required |

| Flavor Penetration | Better flavor diffusion within tobacco leaves | Less uniform penetration, surface-level flavoring |

| Equipment Complexity | Requires integrated dosing and blending systems | Uses standalone flavor application equipment |

| Cost Implications | Potentially higher equipment cost but lower labor | Lower equipment cost, higher labor and time cost |

| Quality Control | Automated monitoring and consistent quality | Manual checks, higher variability risk |

| Flexibility | Less flexible for frequent flavor changes | More flexible for small batch or custom flavors |

Introduction to Inline and Offline Flavor Addition

Inline flavor addition integrates flavoring agents directly into the production line, ensuring consistent taste distribution and reducing processing time. Offline flavor addition involves mixing flavors separately before combining with the main product, allowing for greater customization but increasing handling steps and potential variability. Choosing between inline and offline methods depends on factors like production scale, flavor complexity, and desired control over flavor intensity.

Defining Inline Flavor Addition

Inline flavor addition integrates the flavoring process directly into the production line, allowing real-time mixing and precise control over ingredient ratios. This method minimizes product exposure to contamination and reduces processing time compared to offline flavor addition, which involves adding flavors separately after the primary production step. Inline flavor addition enhances consistency and efficiency in food and beverage manufacturing by streamlining the flavor infusion within continuous operations.

Understanding Offline Flavor Addition

Offline flavor addition involves incorporating flavor compounds during the post-processing stage, allowing precise control over the taste profile after initial production. This method ensures consistent flavor dispersion by mixing flavors thoroughly into the product, often resulting in enhanced stability and intensity compared to inline processes. Understanding offline flavor addition helps you optimize product quality and tailor flavor adjustments without disrupting the main production line.

Key Differences: Inline vs Offline Methods

Inline flavor addition integrates flavoring directly into the production line, ensuring consistent dispersion and real-time quality control, while offline methods involve adding flavors after primary processing, often resulting in longer production times and potential variability in flavor distribution. Inline systems utilize automated dosing and mixing equipment, reducing human error and improving efficiency, whereas offline techniques rely on manual or batch processes that may affect product uniformity. The inline approach enhances scalability and reduces contamination risks compared to offline flavor addition, making it ideal for high-volume manufacturing environments.

Impact on Product Quality and Consistency

Inline flavor addition improves product quality by ensuring uniform flavor distribution through continuous mixing during processing, reducing flavor variation between batches. Consistency is enhanced as inline systems offer precise control over flavor dosage and timing, minimizing human error and integration issues common in offline methods. Offline flavor addition risks uneven mixing and inconsistent flavor profiles due to delayed or manual incorporation, potentially leading to quality deviations and increased product rejects.

Process Efficiency and Downtime Comparison

Inline flavor addition integrates directly into the production line, significantly reducing process variability and enhancing overall efficiency by eliminating batch transfer steps. Offline flavor addition requires halting production for manual mixing, resulting in increased downtime and potential inconsistencies in flavor distribution. Optimizing your process with inline systems minimizes downtime, boosts throughput, and ensures consistent product quality.

Flavor Control and Customization Capabilities

Inline flavor addition offers real-time flavor control, enabling dynamic adjustments during production for precise customization tailored to Your preferences or product requirements. Offline flavor addition relies on predetermined formulations, limiting flexibility and response time to changes in flavor profiles. This makes inline methods superior for maintaining consistent quality and adapting to evolving consumer tastes.

Cost Implications of Each Approach

Inline flavor addition minimizes labor and storage costs by integrating flavoring directly into the production line, reducing the need for separate handling and inventory management. Offline flavor addition often incurs higher expenses due to additional packaging, transportation, and extended processing times, impacting overall operational efficiency. Cost analysis reveals inline methods typically offer lower overhead and improved scalability, making them more economical for large-scale manufacturing.

Industry Applications and Use Cases

Inline flavor addition is widely used in the beverage and dairy industries for real-time flavor customization during production, ensuring consistent taste and reducing batch variations. Offline flavor addition is common in confectionery and bakery sectors where precise, small-batch adjustments are necessary for product development and quality control. Your choice between inline and offline methods depends on production scale, flexibility requirements, and product type.

Choosing the Right Flavor Addition Method

Choosing the right flavor addition method depends largely on your production goals and product consistency requirements. Inline flavor addition integrates flavors directly into the production line, offering precise control and uniform distribution, ideal for high-volume operations. Offline flavoring allows for more flexibility in experimentation and customization but may increase processing time and labor costs.

Inline flavor addition vs offline Infographic

libmatt.com

libmatt.com