Flue-cured tobacco undergoes a drying process using indirect heat, resulting in a lighter, milder flavor ideal for cigarettes, while non-flue-cured tobacco, often air-cured, has a stronger, richer taste suited for cigars or pipe tobacco. Understanding these differences helps you choose the right tobacco type based on flavor preferences and intended use.

Table of Comparison

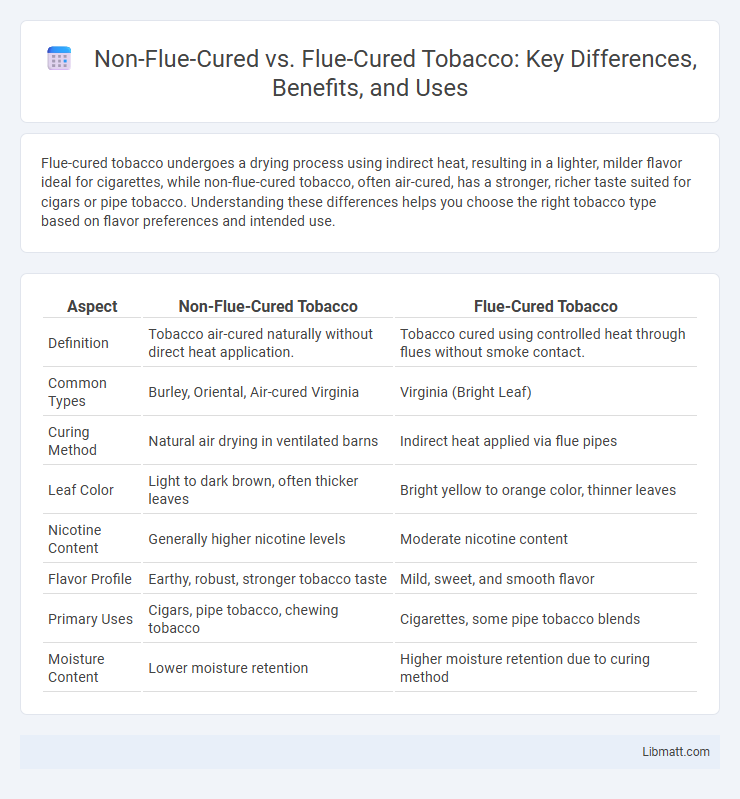

| Aspect | Non-Flue-Cured Tobacco | Flue-Cured Tobacco |

|---|---|---|

| Definition | Tobacco air-cured naturally without direct heat application. | Tobacco cured using controlled heat through flues without smoke contact. |

| Common Types | Burley, Oriental, Air-cured Virginia | Virginia (Bright Leaf) |

| Curing Method | Natural air drying in ventilated barns | Indirect heat applied via flue pipes |

| Leaf Color | Light to dark brown, often thicker leaves | Bright yellow to orange color, thinner leaves |

| Nicotine Content | Generally higher nicotine levels | Moderate nicotine content |

| Flavor Profile | Earthy, robust, stronger tobacco taste | Mild, sweet, and smooth flavor |

| Primary Uses | Cigars, pipe tobacco, chewing tobacco | Cigarettes, some pipe tobacco blends |

| Moisture Content | Lower moisture retention | Higher moisture retention due to curing method |

Introduction to Tobacco Curing Methods

Non-flue-cured tobacco, primarily air-cured, involves drying leaves in ventilated barns with natural airflow, preserving sugars and producing a milder flavor often used in cigars and pipe tobacco. Flue-cured tobacco undergoes a controlled heat curing process inside closed barns with flues, which removes moisture quickly, enhances sugar content, and results in a bright, mild, and aromatic leaf commonly used in cigarettes. Understanding the differences between these curing methods is crucial for tobacco blending, flavor profile development, and end-product quality.

What is Flue-Cured Tobacco?

Flue-cured tobacco is a type of tobacco that undergoes a drying process using heated air without direct exposure to smoke, resulting in a bright, mild leaf predominantly used in cigarettes. This curing technique enhances sugar content and reduces nicotine, offering a smoother flavor compared to non-flue-cured varieties like burley or dark tobaccos. Understanding flue-cured tobacco helps you make informed choices about tobacco products based on taste, nicotine strength, and application.

Defining Non-Flue-Cured Tobacco

Non-flue-cured tobacco is air-cured or sun-cured tobacco that undergoes natural drying without the use of flue heat, preserving its natural flavors and reducing sugar content compared to flue-cured varieties. This curing process results in a leaf with a darker color, stronger aroma, and higher nicotine concentration, commonly used in cigar production and pipe tobacco blends. Flue-cured tobacco, in contrast, is dried using controlled heat from flues, producing a lighter, sweeter leaf primarily used in cigarettes.

Key Differences in Processing Techniques

Non-flue-cured tobacco undergoes air-curing, where leaves are hung in well-ventilated barns and dried naturally over several weeks, preserving higher sugar content and producing a mild flavor. Flue-cured tobacco is dried using a controlled heat source through flues, accelerating the drying process while maintaining a bright, sweet tobacco leaf ideal for cigarettes. These differing techniques impact the chemical composition, moisture content, and overall taste profile, influencing product use and market preferences.

Impact on Tobacco Flavor and Aroma

Non-flue-cured tobacco, often air-cured, retains a natural, earthy flavor with mild sweetness due to slower drying that preserves essential oils, enhancing complex aromas. Flue-cured tobacco undergoes rapid heat drying, which intensifies sugar content and provides a brighter, more robust flavor with a characteristic sweet and spicy aroma. Flavor profiles differ significantly, as non-flue-cured offers a smoother, woodier taste, while flue-cured delivers crispness and pronounced aromatic intensity preferred in many cigarette blends.

Chemical Composition Comparison

Non-flue-cured tobacco generally contains higher levels of nicotine and lower sugar content compared to flue-cured tobacco, which has elevated sugar and reduced nicotine concentrations. The curing process in flue-curing promotes sugar formation through enzymatic activity, resulting in sweeter tobacco flavor profiles. Differences in chemical composition significantly affect the aroma, taste, and combustibility properties of the final tobacco product.

Market Demand and Popularity

Flue-cured tobacco dominates the global market due to its mild flavor and consistent quality, making it highly popular among cigarette manufacturers and consumers. Non-flue-cured tobacco, often used for specialty and pipe tobacco products, caters to niche markets with distinct flavor profiles and traditional processing methods. Understanding these differences helps you target the right audience and optimize product offerings based on market demand and consumer preferences.

Health Implications of Each Method

Non-flue-cured tobacco typically contains higher levels of certain harmful nitrosamines and tar compared to flue-cured tobacco, which undergoes a controlled drying process reducing some toxic compounds. Flue-cured tobacco tends to produce a milder smoke with lower carcinogenic potential, although both methods still pose significant health risks associated with nicotine addiction and respiratory diseases. Studies show that flue-curing's regulated heat and airflow can decrease the concentration of volatile toxins, slightly diminishing but not eliminating the health hazards of tobacco use.

Environmental Considerations

Non-flue-cured tobacco typically involves curing methods that emit fewer volatile organic compounds (VOCs) and particulate matter compared to flue-cured tobacco, which relies on direct heat from combustion and often contributes to higher levels of air pollution. The use of biomass or fossil fuels in flue-curing results in increased greenhouse gas emissions and requires careful management to minimize environmental impact. Sustainable practices in non-flue curing, such as controlled ventilation and alternative energy sources, enhance air quality and reduce the overall carbon footprint of tobacco production.

Conclusion: Choosing Between Non-Flue-Cured and Flue-Cured

Non-flue-cured tobacco offers a natural air-drying process enhancing robust, earthy flavors preferred in cigars and pipe tobacco, while flue-cured tobacco undergoes heat-controlled curing producing a milder taste ideal for cigarettes. The choice between non-flue-cured and flue-cured depends on desired flavor profiles, specific tobacco blends, and end-use applications. Understanding curing methods and their impact on chemical composition guides growers, manufacturers, and consumers in optimizing product quality and satisfaction.

Non-flue-cured vs Flue-cured Infographic

libmatt.com

libmatt.com