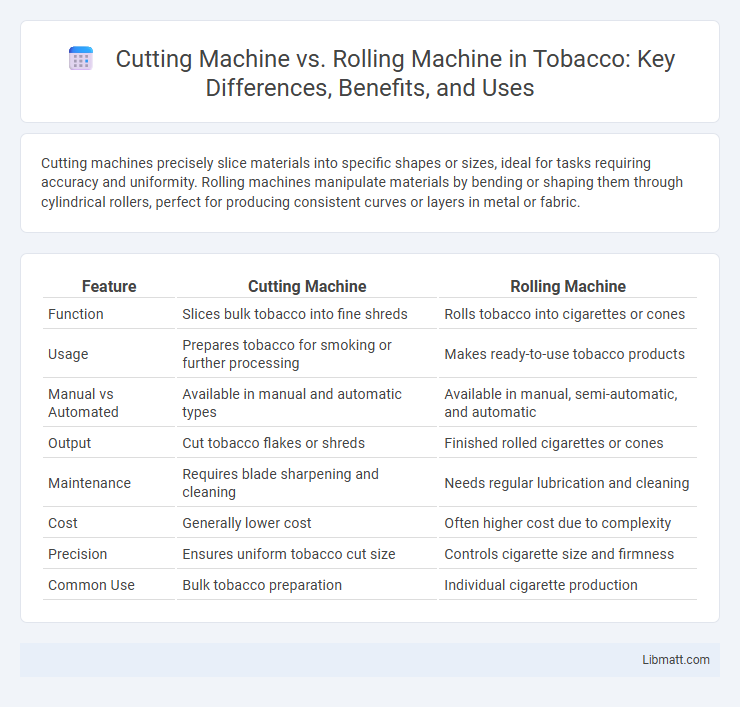

Cutting machines precisely slice materials into specific shapes or sizes, ideal for tasks requiring accuracy and uniformity. Rolling machines manipulate materials by bending or shaping them through cylindrical rollers, perfect for producing consistent curves or layers in metal or fabric.

Table of Comparison

| Feature | Cutting Machine | Rolling Machine |

|---|---|---|

| Function | Slices bulk tobacco into fine shreds | Rolls tobacco into cigarettes or cones |

| Usage | Prepares tobacco for smoking or further processing | Makes ready-to-use tobacco products |

| Manual vs Automated | Available in manual and automatic types | Available in manual, semi-automatic, and automatic |

| Output | Cut tobacco flakes or shreds | Finished rolled cigarettes or cones |

| Maintenance | Requires blade sharpening and cleaning | Needs regular lubrication and cleaning |

| Cost | Generally lower cost | Often higher cost due to complexity |

| Precision | Ensures uniform tobacco cut size | Controls cigarette size and firmness |

| Common Use | Bulk tobacco preparation | Individual cigarette production |

Introduction to Cutting and Rolling Machines

Cutting machines are designed to slice materials into specific shapes or sizes, using blades, lasers, or water jets, essential in industries like manufacturing, textiles, and metalworking. Rolling machines, on the other hand, shape materials by applying pressure through rollers to produce uniform thickness or specific profiles, commonly used in metal forming, paper production, and plastic manufacturing. Your choice between these machines depends on the desired process outcome--cutting for precise separation and rolling for continuous shaping and thickness control.

Key Differences Between Cutting and Rolling Machines

Cutting machines use sharp blades or lasers to divide materials into specific shapes and sizes, focusing on precision and clean edges. Rolling machines apply pressure to shape or flatten materials by passing them through rollers, emphasizing uniform thickness and smooth surfaces. The key difference lies in cutting machines removing material to create desired forms, while rolling machines deform material without cutting to achieve consistent shapes or textures.

Applications of Cutting Machines

Cutting machines are essential in industries such as metal fabrication, textiles, and packaging, where precise material separation is critical. These machines enable accurate cutting of metals, plastics, fabrics, and paper, supporting applications like sheet metal processing, garment manufacturing, and cardboard box production. Your choice of a cutting machine directly impacts production efficiency, product quality, and material waste reduction.

Applications of Rolling Machines

Rolling machines are primarily used in metalworking industries for shaping metal by passing it through pairs of rollers to reduce thickness, improve surface finish, or create uniform thickness sheets and strips. These machines find applications in manufacturing automotive parts, construction materials like steel beams and rails, and producing metal foils and wires with precise dimensions. Your production process benefits from rolling machines when high-volume, consistent metal forming is required, optimizing material properties and enhancing structural integrity.

Efficiency Comparison: Cutting vs Rolling Machines

Cutting machines offer precise, fast material separation, making them highly efficient for tasks requiring detailed shapes and minimal waste. Rolling machines excel in efficiency when shaping or bending materials continuously, reducing manual labor and speeding up production lines. Your choice depends on whether you prioritize exact cuts or streamlined forming processes for optimal operational efficiency.

Material Compatibility

Cutting machines excel in precision slicing of diverse materials such as metals, plastics, and fabrics, making them ideal for detailed or intricate designs. Rolling machines are specifically optimized for shaping and compressing uniform materials like sheets of metal, rubber, and textiles, ensuring consistent thickness and smooth surfaces. Your choice depends on whether your project requires exact cuts or continuous material formation.

Cost Analysis and Investment Considerations

Cutting machines generally require higher initial investment due to advanced technology and precision components, but they offer reduced material waste and lower labor costs, resulting in long-term savings. Rolling machines have lower upfront costs but can incur increased maintenance expenses and higher operational energy consumption over time. Evaluating total cost of ownership, including equipment purchase, maintenance, energy use, and productivity impact, is crucial for optimizing investment decisions between cutting and rolling machinery.

Maintenance and Durability

Cutting machines require regular blade sharpening and lubrication to maintain precision and extend tool life, while rolling machines demand consistent inspection of rollers and bearings to prevent wear and ensure smooth operation. Durability in cutting machines largely depends on the quality of blades and motor components, whereas rolling machines benefit from robust frame construction and corrosion-resistant materials for enhanced longevity. Proper maintenance of each machine type directly impacts Your equipment's performance and lifespan, reducing downtime and costly repairs.

Safety Features and Precautions

Cutting machines are equipped with advanced safety features such as blade guards, emergency stop buttons, and automatic shut-off sensors to prevent accidents during operation. Rolling machines incorporate safety mechanisms like pressure sensors, protective covers, and lockout/tagout systems to avoid hazards related to material entanglement or crushing. Operators must always follow proper safety protocols, including wearing personal protective equipment (PPE) and receiving adequate training for both cutting and rolling machinery to minimize injury risks.

Choosing the Right Machine for Your Needs

Selecting the right machine depends on your specific production requirements, where cutting machines excel in precision slicing or shaping materials, while rolling machines are ideal for forming continuous sheets or cylindrical shapes. Understanding the material type, thickness, and desired end product helps determine whether the cutting action or rolling process better suits your manufacturing goals. Your choice impacts efficiency, quality, and overall operational costs, making it crucial to evaluate machine capabilities against your project demands.

Cutting machine vs Rolling machine Infographic

libmatt.com

libmatt.com