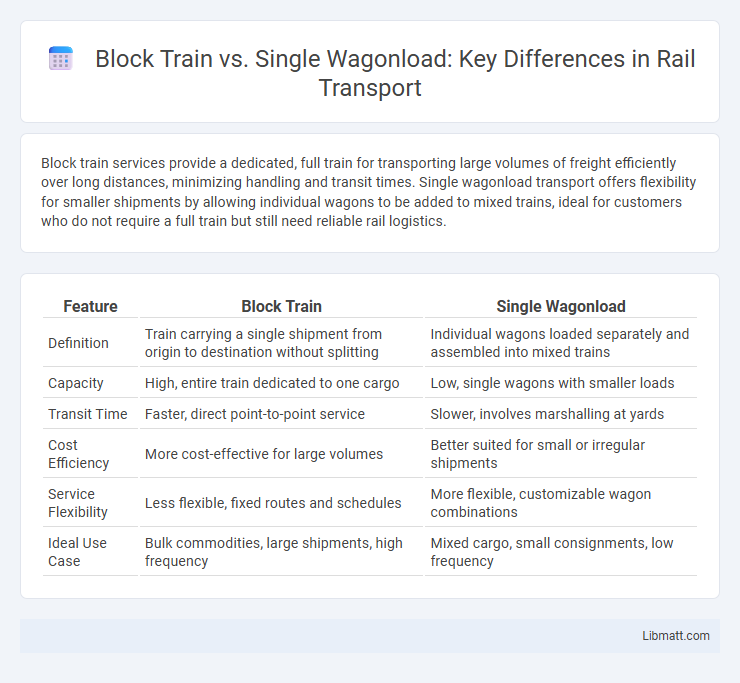

Block train services provide a dedicated, full train for transporting large volumes of freight efficiently over long distances, minimizing handling and transit times. Single wagonload transport offers flexibility for smaller shipments by allowing individual wagons to be added to mixed trains, ideal for customers who do not require a full train but still need reliable rail logistics.

Table of Comparison

| Feature | Block Train | Single Wagonload |

|---|---|---|

| Definition | Train carrying a single shipment from origin to destination without splitting | Individual wagons loaded separately and assembled into mixed trains |

| Capacity | High, entire train dedicated to one cargo | Low, single wagons with smaller loads |

| Transit Time | Faster, direct point-to-point service | Slower, involves marshalling at yards |

| Cost Efficiency | More cost-effective for large volumes | Better suited for small or irregular shipments |

| Service Flexibility | Less flexible, fixed routes and schedules | More flexible, customizable wagon combinations |

| Ideal Use Case | Bulk commodities, large shipments, high frequency | Mixed cargo, small consignments, low frequency |

Introduction to Rail Freight: Block Train vs Single Wagonload

Block trains consist of a full set of railcars dedicated to a single shipment, providing faster transit and reduced handling compared to single wagonload services, which involve individual wagons from multiple customers consolidated into one train. Block trains optimize efficiency for large-volume, time-sensitive cargo, while single wagonload offers flexibility for smaller shipments and diverse destinations. Your choice between these rail freight options depends on shipment size, delivery speed, and cost considerations.

Defining Block Train Operations

Block train operations involve the transportation of freight where all wagons are from the same origin to the same destination without being split or reassembled en route, optimizing efficiency and reducing handling time. Unlike single wagonload services, which transport individual wagons destined for various locations, block trains enable higher capacity and faster transit times by minimizing logistical complexities. Your supply chain benefits from increased reliability and cost savings when choosing block train operations for large-volume shipments.

Understanding Single Wagonload Services

Single wagonload services provide flexible, tailored shipping solutions by transporting individual freight wagons rather than entire block trains, enabling efficient handling of smaller consignments. This approach supports multiple destinations within one journey, optimizing logistics for diverse cargo types and reducing transit times for shipments that do not require full train capacity. Single wagonload services enhance supply chain responsiveness, especially for industries with fluctuating shipment volumes or specialized routing needs.

Key Differences Between Block Train and Single Wagonload

Block trains consist of a series of wagons carrying the same load and traveling directly from origin to destination without intermediate shunting, ensuring faster and more efficient transport. Single wagonload shipments involve individual wagons that carry different goods and often require sorting and assembling at various terminals, leading to longer transit times. Your choice between block train and single wagonload depends on shipment volume, speed requirements, and cost considerations.

Cost Comparison: Block Train vs Single Wagonload

Block trains offer a cost advantage over single wagonload shipments by maximizing economies of scale through dedicated, full-train loads that reduce per-unit transportation expenses. Single wagonload services incur higher costs per ton due to additional handling, shunting, and longer dwell times at marshalling yards, leading to increased labor and infrastructure expenses. The efficiency of block trains in minimizing transit times and simplifying logistics results in a lower overall cost structure for large-volume shipments compared to the fragmented nature of single wagonload transport.

Operational Efficiency and Reliability

Block trains deliver superior operational efficiency and reliability by transporting entire trainloads from origin to destination without intermediate reclassification, minimizing handling time and delays. Single wagonload services require multiple shunting and reassembly processes at marshalling yards, increasing transit time and risk of scheduling disruptions. The streamlined logistics of block trains result in higher punctuality rates and reduced operational complexity compared to fragmented single wagonload consignments.

Environmental Impact and Sustainability

Block trains significantly reduce carbon emissions per ton-kilometer by transporting large volumes of goods in a single, continuous movement, minimizing the need for additional handling and transfers. Single wagonload transport, while flexible for smaller shipments, generally incurs higher energy consumption and greater emissions due to increased shunting, less efficient loading, and more frequent stops. Optimizing logistics with block trains supports sustainable supply chains by enhancing fuel efficiency and lowering the environmental footprint compared to fragmented single wagonload operations.

Suitable Cargo Types for Each Mode

Block trains are ideal for bulk commodities like coal, grain, and chemicals that require dedicated, high-volume, and consistent shipment schedules. Single wagonload services suit diverse cargo types, including smaller industrial goods, machinery parts, and parcels that need flexible, less frequent delivery. The choice depends on cargo volume, frequency, and handling requirements, optimizing efficiency and cost-effectiveness in rail freight logistics.

Case Studies: Industry Applications

Case studies in the rail transport sector reveal significant efficiency gains when using block trains compared to single wagonload operations, particularly in industries such as automotive manufacturing and bulk commodities like coal and minerals. Block trains often enable faster turnaround times and reduced handling costs due to their fixed composition and dedicated routes, as demonstrated by logistical improvements at large-scale production facilities. Your supply chain can benefit from enhanced reliability and reduced freight expenses by adopting block train solutions tailored to high-volume, repetitive cargo movements.

Choosing the Right Rail Freight Solution

Choosing the right rail freight solution depends on shipment volume, delivery speed, and cost-effectiveness. Block trains offer dedicated service for high-volume loads with faster transit times, reducing handling risks and improving reliability. Single wagonload suits smaller shipments allowing flexible routing and consolidating cargo, making it ideal for diverse supply chains where you need cost control and adaptability.

block train vs single wagonload Infographic

libmatt.com

libmatt.com