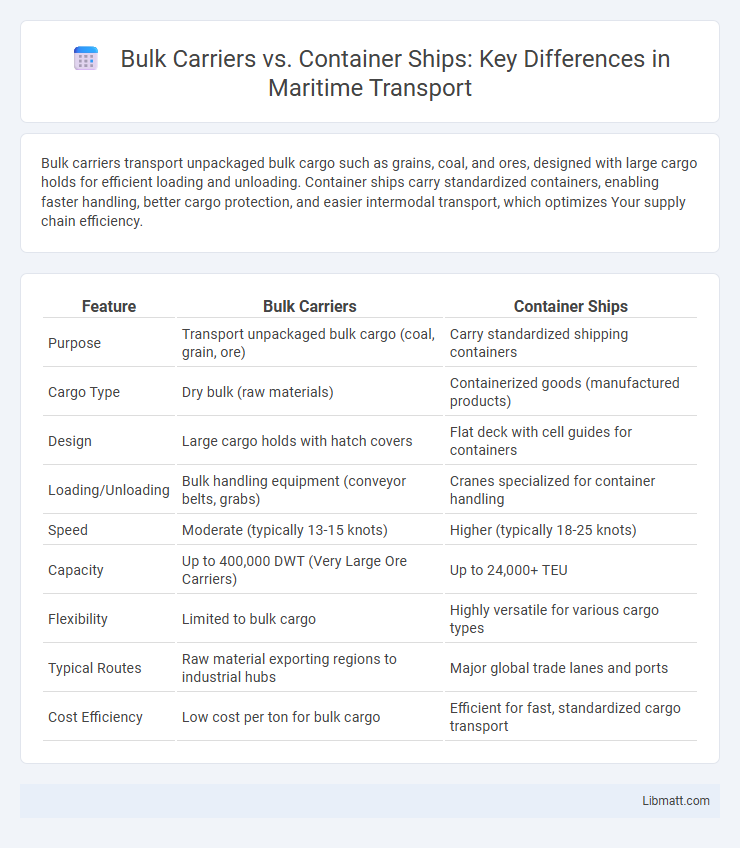

Bulk carriers transport unpackaged bulk cargo such as grains, coal, and ores, designed with large cargo holds for efficient loading and unloading. Container ships carry standardized containers, enabling faster handling, better cargo protection, and easier intermodal transport, which optimizes Your supply chain efficiency.

Table of Comparison

| Feature | Bulk Carriers | Container Ships |

|---|---|---|

| Purpose | Transport unpackaged bulk cargo (coal, grain, ore) | Carry standardized shipping containers |

| Cargo Type | Dry bulk (raw materials) | Containerized goods (manufactured products) |

| Design | Large cargo holds with hatch covers | Flat deck with cell guides for containers |

| Loading/Unloading | Bulk handling equipment (conveyor belts, grabs) | Cranes specialized for container handling |

| Speed | Moderate (typically 13-15 knots) | Higher (typically 18-25 knots) |

| Capacity | Up to 400,000 DWT (Very Large Ore Carriers) | Up to 24,000+ TEU |

| Flexibility | Limited to bulk cargo | Highly versatile for various cargo types |

| Typical Routes | Raw material exporting regions to industrial hubs | Major global trade lanes and ports |

| Cost Efficiency | Low cost per ton for bulk cargo | Efficient for fast, standardized cargo transport |

Overview of Bulk Carriers and Container Ships

Bulk carriers are specialized vessels designed to transport unpackaged bulk cargo such as coal, grain, and ore, featuring large cargo holds for efficient loading and unloading. Container ships carry standardized intermodal containers, enabling fast handling and streamlined global trade, with capacities measured in TEUs (twenty-foot equivalent units). While bulk carriers focus on volume and heavy materials, container ships prioritize speed, versatility, and cargo protection across various industries.

Key Differences in Design and Structure

Bulk carriers feature large, open cargo holds designed for transporting unpackaged bulk materials like coal, grain, and ore, with robust hulls to withstand heavy loads and uneven weight distribution. Container ships are built with cell guides and a flat deck layout to securely stack standardized shipping containers, optimizing space and facilitating efficient loading and unloading. The structural design of bulk carriers emphasizes reinforced bulkheads and hatch covers, while container ships prioritize stability and weight distribution to handle container stacks and prevent shifting during transit.

Cargo Types Handled by Each Vessel

Bulk carriers primarily transport unpackaged bulk cargo such as coal, iron ore, grain, and cement, optimizing their design for large volumes of homogeneous goods stored directly in cargo holds. Container ships handle standardized cargo containers carrying manufactured goods, electronics, textiles, and perishable items, facilitating efficient loading and unloading through containerized logistics. The selection between these vessels depends on the nature and packaging of the cargo, impacting global supply chain strategies for raw materials versus finished products.

Loading and Unloading Processes

Bulk carriers utilize large hatches and cranes or conveyor belts for loading and unloading loose cargo such as coal, grain, or ore, often requiring specialized port facilities for efficient handling. Container ships rely on standardized containers loaded and unloaded using gantry cranes, enabling faster turnaround times and streamlined logistics in container terminals. The structured process in container shipping maximizes operational efficiency, whereas bulk carriers demand more flexible but time-consuming handling techniques.

Operational Efficiency and Speed

Bulk carriers typically operate at slower cruising speeds of around 12-15 knots, prioritizing fuel efficiency and cargo volume over transit time, making them optimal for heavy, bulk commodities like coal, grain, and ores. Container ships average faster speeds of 18-25 knots to meet tight shipping schedules and supply chain demands, leveraging advanced engine technology and streamlined hull designs for enhanced operational efficiency during intermodal transport. The difference in speed and efficiency reflects the trade-off between maximizing cargo capacity and minimizing transit time in global maritime logistics.

Construction Costs and Maintenance

Bulk carriers often have lower construction costs than container ships due to simpler hull designs and fewer specialized components. Container ships require advanced engineering for container stacking systems and reinforced decks, increasing initial investment and ongoing maintenance expenses. Your decision depends on balancing these cost factors with operational needs in shipping bulk commodities or containerized goods.

Environmental Impact and Fuel Consumption

Bulk carriers generally have lower fuel consumption per ton of cargo compared to container ships due to their simpler design and slower speeds, resulting in reduced greenhouse gas emissions per shipment. Container ships, while faster and capable of carrying more diverse cargo, tend to consume more fuel and produce higher CO2 emissions because of their complex engine systems and frequent port calls. Advances in fuel-efficient technologies and alternative fuels are crucial for both vessel types to minimize their environmental impact in global shipping.

Global Trade Routes and Market Uses

Bulk carriers dominate global trade routes by transporting large volumes of raw materials like coal, iron ore, and grain across major corridors such as Australia to China and Brazil to Europe. Container ships serve diverse markets by facilitating the rapid movement of manufactured goods, electronics, and consumer products along established routes including Asia-Europe and transpacific lanes. Your choice between these vessels depends on cargo type and trade demands within these specialized maritime networks.

Safety Measures and Cargo Security

Bulk carriers implement advanced monitoring systems and reinforced hatch covers to prevent cargo shifting and water ingress, enhancing ship stability and safety during voyages. Container ships prioritize stack lashing technology and real-time tracking systems to secure containers against movement and theft, ensuring cargo integrity in adverse sea conditions. Both vessel types adhere to International Maritime Organization (IMO) regulations, including the SOLAS convention, to uphold stringent safety and security standards throughout maritime transport.

Future Trends in Bulk and Container Shipping

Future trends in bulk and container shipping emphasize increasing automation, digitalization, and sustainability measures to reduce carbon emissions and improve operational efficiency. Bulk carriers are adopting smart sensors and AI to optimize cargo handling and fuel consumption, while container ships focus on larger capacities and eco-friendly propulsion technologies like LNG and hybrid engines. Your shipping strategies should align with these innovations to stay competitive and meet evolving environmental regulations.

bulk carriers vs container ships Infographic

libmatt.com

libmatt.com