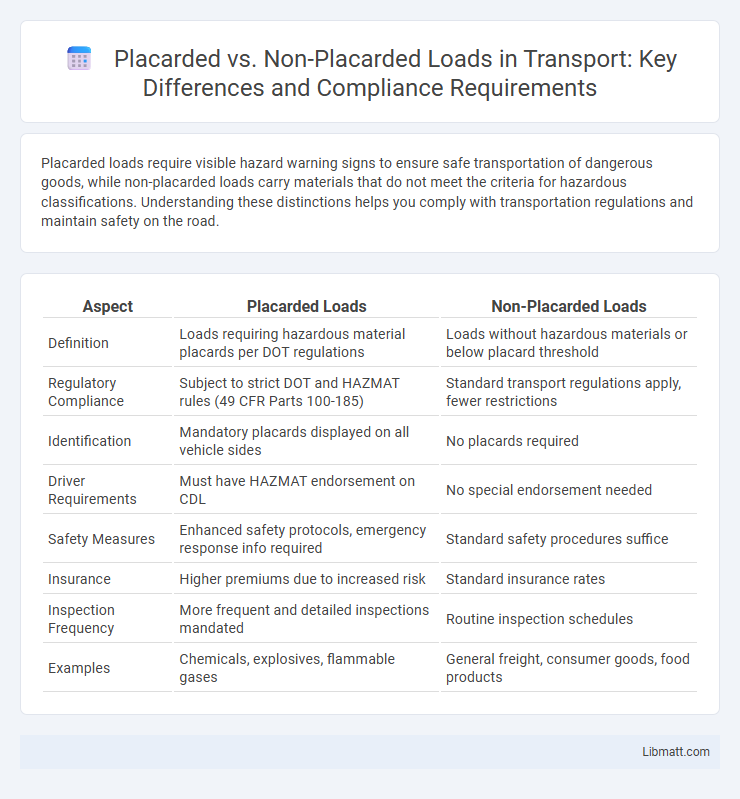

Placarded loads require visible hazard warning signs to ensure safe transportation of dangerous goods, while non-placarded loads carry materials that do not meet the criteria for hazardous classifications. Understanding these distinctions helps you comply with transportation regulations and maintain safety on the road.

Table of Comparison

| Aspect | Placarded Loads | Non-Placarded Loads |

|---|---|---|

| Definition | Loads requiring hazardous material placards per DOT regulations | Loads without hazardous materials or below placard threshold |

| Regulatory Compliance | Subject to strict DOT and HAZMAT rules (49 CFR Parts 100-185) | Standard transport regulations apply, fewer restrictions |

| Identification | Mandatory placards displayed on all vehicle sides | No placards required |

| Driver Requirements | Must have HAZMAT endorsement on CDL | No special endorsement needed |

| Safety Measures | Enhanced safety protocols, emergency response info required | Standard safety procedures suffice |

| Insurance | Higher premiums due to increased risk | Standard insurance rates |

| Inspection Frequency | More frequent and detailed inspections mandated | Routine inspection schedules |

| Examples | Chemicals, explosives, flammable gases | General freight, consumer goods, food products |

Understanding Placarded vs. Non-Placarded Loads

Placarded loads are hazardous materials that require visible warning signs on transport vehicles, alerting emergency responders and the public to the presence of dangerous goods. Non-placarded loads consist of materials that do not meet the threshold quantities or hazard classifications necessitating placards under regulations such as the DOT's Hazardous Materials Regulations (HMR). Understanding the distinction ensures compliance with safety protocols and legal requirements, protecting your cargo, vehicle, and crew from potential risks during transportation.

Regulatory Requirements for Placarded Loads

Regulatory requirements for placarded loads mandate specific hazardous materials be identified with standardized placards displaying hazard class symbols and numbers, ensuring compliance with the U.S. Department of Transportation (DOT) and OSHA regulations. Drivers transporting placarded loads must possess proper endorsements on their commercial driver's licenses (CDL) and adhere to weight limits, routing restrictions, and driver training under the Hazardous Materials Regulations (HMR, 49 CFR Parts 100-185). Non-compliance with placarding requirements results in fines, increased inspection frequency, and heightened liability for carriers and shippers.

Key Differences Between Placarded and Non-Placarded Cargo

Placarded loads require visible hazard identification signs on the vehicle, ensuring proper handling and compliance with regulatory safety standards for transporting dangerous goods. Non-placarded loads consist of materials that do not meet the hazard threshold or quantity, eliminating the need for such warning labels during transit. Understanding these distinctions helps you maintain safety protocols and avoid legal penalties in cargo transportation.

Common Types of Placarded Loads

Common types of placarded loads include hazardous materials such as flammable liquids, corrosive substances, explosives, and toxic gases. These loads require specific placards for identification, ensuring compliance with safety regulations during transport. Understanding the distinctions between placarded and non-placarded loads helps you manage the risks associated with hazardous shipments effectively.

Safety Protocols for Placarded Shipments

Placarded shipments require strict adherence to safety protocols including proper labeling, secure packaging, and compliance with hazardous material regulations to prevent accidents during transportation. Drivers must possess specialized training and documentation to handle and transport placarded loads safely, ensuring public and environmental protection. Your responsibility includes verifying that all safety measures are in place before dispatching or accepting these high-risk shipments.

Documentation Needed for Placarded vs. Non-Placarded Loads

Documentation for placarded loads requires a detailed shipping paper or manifest, including hazardous material descriptions, proper shipping names, hazard classes, identification numbers, and emergency response information. Non-placarded loads typically demand standard freight bills or simple invoices with fewer safety details, as they do not involve hazardous materials. Ensuring your documentation meets regulatory standards for placarded loads is essential for compliance and safety during transport.

Transportation Restrictions for Hazardous Materials

Placarded loads transporting hazardous materials must comply with strict transportation restrictions including specific routing, time-of-day travel limits, and mandatory driver training to ensure public safety. Non-placarded loads, containing lower-risk quantities or non-hazardous materials, face fewer routing restrictions but still must adhere to general safety regulations. Compliance with the Hazardous Materials Regulations (HMR) issued by the U.S. Department of Transportation is critical for both placarded and non-placarded shipments to prevent accidents and legal penalties.

Liability and Insurance Considerations

Placarded loads require specialized insurance coverage due to the higher risks associated with transporting hazardous materials, increasing both liability and premium costs. Non-placarded loads generally involve standard liability insurance with fewer restrictions and lower premiums, reflecting reduced risk exposure. Your choice between placarded and non-placarded loads significantly impacts your insurance obligations and potential liability in accident claims.

Training Requirements for Handling Placarded Loads

Handling placarded loads demands specialized training to comply with hazardous materials regulations, such as those outlined by OSHA and DOT. Training programs cover hazard recognition, proper loading and unloading techniques, emergency response procedures, and use of personal protective equipment (PPE). Workers must receive certification, periodic refresher courses, and specific instruction on reading placards and understanding material safety data sheets (MSDS) to ensure safe transport and handling of hazardous materials.

Best Practices for Compliance and Risk Management

Placarded loads, which contain hazardous materials requiring specific signage, demand strict adherence to DOT regulations, including proper labeling, documentation, and driver training to ensure compliance and mitigate risks. Non-placarded loads, although less regulated, still require accurate cargo classification and securement to prevent accidents and liability issues. Implementing comprehensive inspection protocols and continuous compliance monitoring supports effective risk management for both load types.

placarded vs non-placarded loads Infographic

libmatt.com

libmatt.com