Double-stack trains maximize freight capacity by stacking two containers vertically, significantly improving efficiency and reducing shipping costs compared to single-stack trains that carry containers in a single layer. Choosing double-stack over single-stack trains can optimize your logistics by increasing volume without requiring additional railcars or track space.

Table of Comparison

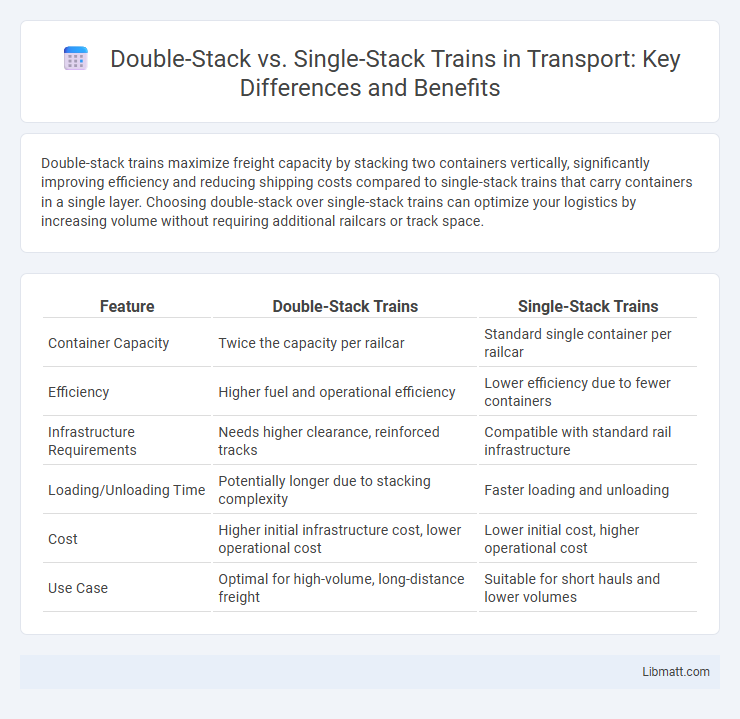

| Feature | Double-Stack Trains | Single-Stack Trains |

|---|---|---|

| Container Capacity | Twice the capacity per railcar | Standard single container per railcar |

| Efficiency | Higher fuel and operational efficiency | Lower efficiency due to fewer containers |

| Infrastructure Requirements | Needs higher clearance, reinforced tracks | Compatible with standard rail infrastructure |

| Loading/Unloading Time | Potentially longer due to stacking complexity | Faster loading and unloading |

| Cost | Higher initial infrastructure cost, lower operational cost | Lower initial cost, higher operational cost |

| Use Case | Optimal for high-volume, long-distance freight | Suitable for short hauls and lower volumes |

Introduction to Train Stacking: Double-Stack vs Single-Stack

Double-stack trains double container capacity by stacking one container atop another, maximizing cargo volume on each railcar compared to single-stack trains that carry one container per car. Single-stack trains offer simplified loading and unloading processes, but double-stack configurations optimize space utilization and reduce transportation costs per container. Rail infrastructure, such as clearance heights and terminal equipment, plays a critical role in determining the feasibility of double-stack stacking on specific routes.

Key Differences Between Double-Stack and Single-Stack Trains

Double-stack trains feature two layers of intermodal containers stacked vertically, significantly increasing cargo capacity and reducing transportation costs compared to single-stack trains, which carry only one layer of containers. Double-stack trains require specialized clearances and infrastructure such as taller tunnels and bridges, while single-stack trains have fewer height restrictions and greater route flexibility. Your choice between the two depends on balancing efficiency gains with infrastructure compatibility and operational constraints.

Capacity and Efficiency: A Comparative Analysis

Double-stack trains significantly enhance capacity by allowing two layers of intermodal containers stacked vertically, effectively doubling the freight volume compared to single-stack trains. This configuration improves operational efficiency through reduced fuel consumption per container mile and lowers transportation costs by maximizing cargo per trip. Railroads implementing double-stack technology benefit from increased network throughput and better utilization of track and terminal infrastructure.

Infrastructure Requirements for Double-Stack and Single-Stack

Double-stack trains require taller clearances and stronger bridges to accommodate the increased height of two stacked containers, which demands significant modifications to existing rail infrastructure. Single-stack trains, with containers placed only on one level, have lower clearance and structural requirements, making them easier to integrate into current rail networks. Your choice between double-stack and single-stack will impact the scale of infrastructure investment needed for bridges, tunnels, and overhead wires.

Cost Implications of Train Stacking Strategies

Double-stack trains offer significant cost advantages by maximizing container capacity on a single trip, reducing fuel expenses and overall transportation costs compared to single-stack trains. Although double-stack operations may require specialized infrastructure upgrades and higher initial investments, the long-term savings in operational efficiency and increased freight volume outweigh these expenses. Your logistics strategy can benefit from balancing initial costs with sustained economic gains through optimized train stacking methods.

Geographic Suitability and Track Compatibility

Double-stack trains offer higher freight capacity but require greater vertical clearance, making them suitable primarily for routes with ample tunnel heights and bridge clearances, such as many North American rail corridors. Single-stack trains are more adaptable to diverse geographic regions with restrictive infrastructure, commonly used in Europe and parts of Asia where reduced overhead clearance limits double-stack operation. Track compatibility for double-stack trains demands reinforced rail beds and wider clearances, whereas single-stack trains can operate on older and narrower gauge tracks without extensive modifications.

Impact on Railway Operations and Scheduling

Double-stack trains significantly enhance railway operations by increasing cargo capacity without requiring additional train length, leading to more efficient track usage and reduced congestion. Their increased height demands infrastructure adaptations, such as higher clearances and stronger bridges, which can affect scheduling due to maintenance and route restrictions. Your railway scheduling must account for these factors to optimize turnaround times and minimize delays, ensuring seamless integration of double-stack trains into existing networks.

Environmental Considerations: Emissions and Fuel Efficiency

Double-stack trains significantly reduce emissions per ton-mile compared to single-stack trains by transporting more containers in a single trip, enhancing fuel efficiency and lowering overall carbon footprint. The increased load capacity of double-stack trains decreases the number of trips required, leading to reduced diesel fuel consumption and fewer greenhouse gas emissions. Your choice of transport method can directly impact environmental sustainability by favoring double-stack trains for greener and more efficient freight movement.

Case Studies: Real-World Applications of Double-Stack and Single-Stack Trains

Double-stack trains offer significant efficiency advantages in freight transportation, as demonstrated by their extensive use in North American intermodal corridors, where they increase container capacity by stacking two containers vertically, reducing rail congestion and cutting costs. Single-stack trains remain vital in regions with height restrictions, such as Europe and parts of Asia, where infrastructure limits the clearances needed for double-stacking, demonstrating their practical adaptation to local rail networks. Your logistics strategy can benefit from analyzing case studies like the Norfolk Southern Railway's double-stack implementation for bulk shipments versus the Deutsche Bahn's optimization of single-stack trains for European urban and mountainous routes.

Future Trends in Freight Transportation: Stacking Innovations

Double-stack trains significantly increase freight capacity by stacking containers two high, optimizing rail network efficiency and reducing fuel consumption per ton-mile. Advances in stacking technology, such as adjustable double-stack well cars and enhanced clearance infrastructure, are poised to meet growing demand while minimizing environmental impact. Your supply chain can leverage these innovations to achieve higher throughput and sustainable freight transportation in the future.

double-stack vs single-stack trains Infographic

libmatt.com

libmatt.com