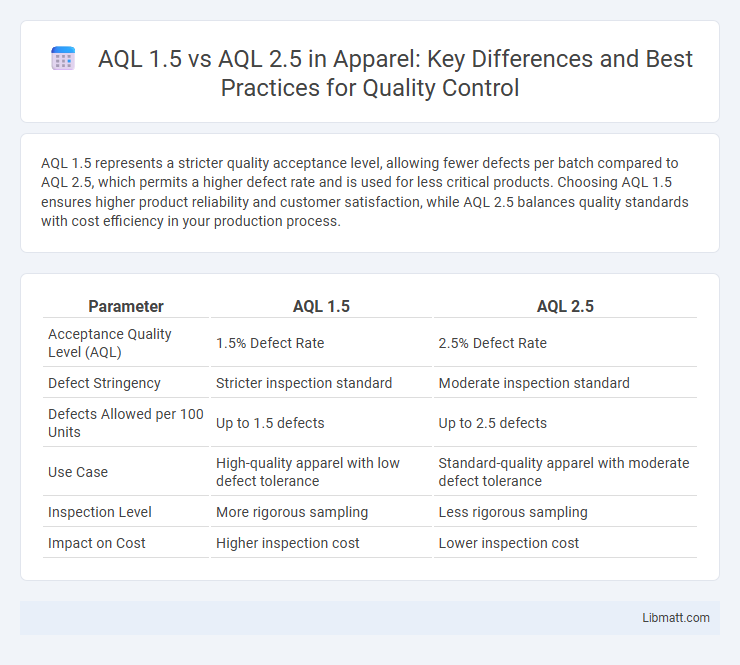

AQL 1.5 represents a stricter quality acceptance level, allowing fewer defects per batch compared to AQL 2.5, which permits a higher defect rate and is used for less critical products. Choosing AQL 1.5 ensures higher product reliability and customer satisfaction, while AQL 2.5 balances quality standards with cost efficiency in your production process.

Table of Comparison

| Parameter | AQL 1.5 | AQL 2.5 |

|---|---|---|

| Acceptance Quality Level (AQL) | 1.5% Defect Rate | 2.5% Defect Rate |

| Defect Stringency | Stricter inspection standard | Moderate inspection standard |

| Defects Allowed per 100 Units | Up to 1.5 defects | Up to 2.5 defects |

| Use Case | High-quality apparel with low defect tolerance | Standard-quality apparel with moderate defect tolerance |

| Inspection Level | More rigorous sampling | Less rigorous sampling |

| Impact on Cost | Higher inspection cost | Lower inspection cost |

Understanding AQL: Definition and Purpose

AQL 1.5 and AQL 2.5 represent specific Acceptance Quality Limits used in quality control to define the maximum number of defective items acceptable in a sample batch. Understanding AQL involves recognizing it as a statistically derived criterion ensuring that Your products meet predefined quality standards without inspecting every unit. The shift from AQL 1.5 to AQL 2.5 typically indicates a relaxation in acceptable defect levels, reflecting changes in production tolerance or inspection rigor.

What Does AQL 1.5 Mean?

AQL 1.5 refers to an Acceptable Quality Level where 1.5% of a batch's samples are allowed to be defective before the entire batch is rejected, ensuring strict quality control standards. This level is commonly used in manufacturing to maintain high product reliability and customer satisfaction. Understanding AQL 1.5 helps you determine acceptable defect rates in quality inspections compared to higher levels like AQL 2.5, which permits a greater proportion of defects.

What Does AQL 2.5 Mean?

AQL 2.5 means that in a batch of inspected products, the maximum number of defective units allowed per hundred items is 2.5, aligning with moderate quality control standards. Compared to AQL 1.5, which permits fewer defects, AQL 2.5 represents a slightly higher tolerance for defects, often applied in less critical applications where minor defects are acceptable. Understanding your product's AQL level helps you manage quality expectations and maintain consistent manufacturing standards.

Key Differences Between AQL 1.5 and AQL 2.5

AQL 1.5 and AQL 2.5 differ primarily in their acceptance quality limits, with AQL 1.5 allowing higher defect rates compared to the more stringent AQL 2.5 standard. AQL 2.5 enforces tighter quality control, resulting in fewer acceptable defects per sample batch, thus ensuring improved product reliability. These differences significantly impact quality inspection protocols and consumer satisfaction levels in manufacturing and production environments.

Impact of AQL Levels on Product Quality

AQL 1.5 represents a stricter acceptance quality level compared to AQL 2.5, resulting in fewer defective items allowed per batch and thereby enhancing product reliability. Choosing AQL 1.5 means your products undergo more rigorous inspection, reducing the risk of defects reaching customers and improving overall customer satisfaction. Manufacturers aiming for higher quality standards often prefer AQL 1.5 to maintain superior consistency in product performance and safety.

Industry Standards: When to Use AQL 1.5 vs AQL 2.5

AQL 1.5 is commonly applied in manufacturing sectors where minor defects are acceptable and cost-efficiency is prioritized, such as consumer electronics or apparel industries. AQL 2.5 is favored for critical industries like pharmaceuticals and aerospace, where stricter quality control standards are essential to ensure product safety and regulatory compliance. Selecting between AQL 1.5 and AQL 2.5 depends on the acceptable risk level, industry requirements, and the criticality of the product's functionality.

Risk Management: Defects Accepted at AQL 1.5 vs 2.5

AQL 1.5 permits a lower defect rate, typically around 1.5%, indicating stricter quality controls with fewer defects accepted compared to AQL 2.5, which allows approximately 2.5% defects. This difference impacts risk management by reducing the probability of defective products reaching customers under AQL 1.5, enhancing product reliability. Higher AQL levels, such as 2.5, increase acceptance of defects, potentially raising risks related to customer dissatisfaction and product recalls.

Cost Implications of Different AQL Levels

AQL 1.5 typically results in higher inspection costs due to stricter acceptance criteria and more rejections, leading to increased rework or scrap expenses. In contrast, AQL 2.5 allows for a higher defect rate, reducing inspection costs but potentially increasing costs related to customer dissatisfaction and warranty claims. Your choice between AQL 1.5 and AQL 2.5 should balance upfront inspection expenses against long-term quality and service costs.

Choosing the Right AQL for Your Product

Selecting between AQL 1.5 and AQL 2.5 depends on the acceptable quality level and risk tolerance for your product. AQL 1.5 sets a stricter threshold, allowing fewer defects per batch and is ideal for high-precision industries like pharmaceuticals or aerospace. AQL 2.5 offers a more lenient acceptance rate, suitable for less critical products or those with higher production variability, balancing quality control with manufacturing efficiency.

Summary: AQL 1.5 vs AQL 2.5 – Which Is Better?

AQL 2.5 offers enhanced precision and a more comprehensive sampling framework compared to AQL 1.5, enabling improved defect detection and quality control. The updated standard supports lower acceptance numbers and tighter inspection criteria, which reduce the risk of faulty products passing inspection. Organizations aiming for stricter quality assurance typically favor AQL 2.5 for its balance between statistical rigor and operational efficiency.

AQL 1.5 vs AQL 2.5 Infographic

libmatt.com

libmatt.com