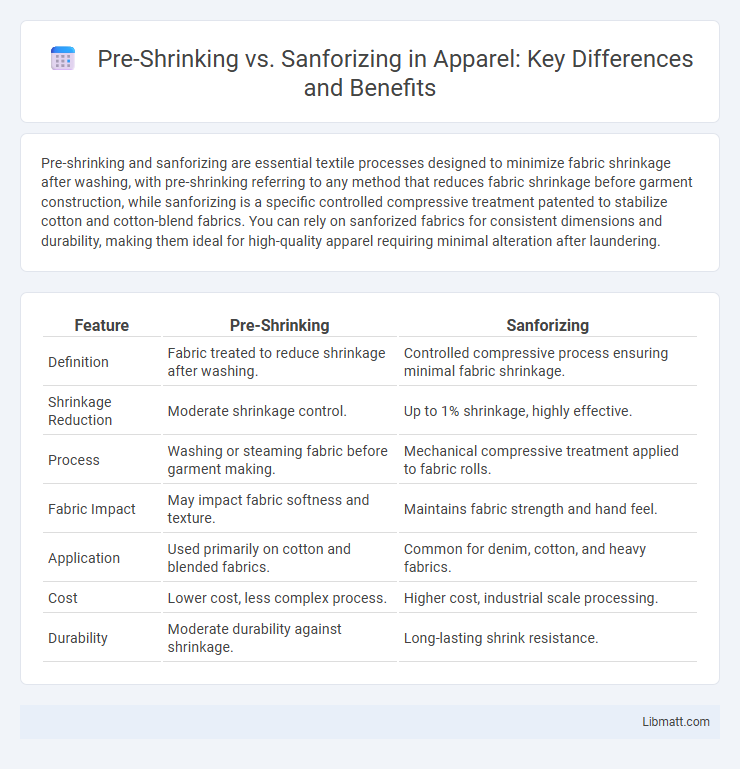

Pre-shrinking and sanforizing are essential textile processes designed to minimize fabric shrinkage after washing, with pre-shrinking referring to any method that reduces fabric shrinkage before garment construction, while sanforizing is a specific controlled compressive treatment patented to stabilize cotton and cotton-blend fabrics. You can rely on sanforized fabrics for consistent dimensions and durability, making them ideal for high-quality apparel requiring minimal alteration after laundering.

Table of Comparison

| Feature | Pre-Shrinking | Sanforizing |

|---|---|---|

| Definition | Fabric treated to reduce shrinkage after washing. | Controlled compressive process ensuring minimal fabric shrinkage. |

| Shrinkage Reduction | Moderate shrinkage control. | Up to 1% shrinkage, highly effective. |

| Process | Washing or steaming fabric before garment making. | Mechanical compressive treatment applied to fabric rolls. |

| Fabric Impact | May impact fabric softness and texture. | Maintains fabric strength and hand feel. |

| Application | Used primarily on cotton and blended fabrics. | Common for denim, cotton, and heavy fabrics. |

| Cost | Lower cost, less complex process. | Higher cost, industrial scale processing. |

| Durability | Moderate durability against shrinkage. | Long-lasting shrink resistance. |

Introduction to Fabric Shrinkage

Fabric shrinkage occurs when natural fibers contract after exposure to moisture or heat, affecting garment fit and durability. Pre-shrinking methods like sanforizing mechanically compress fabric before cutting, reducing post-production shrinkage to less than 1%. Comparing pre-shrinking to other techniques highlights sanforizing's precision in stabilizing dimensions, crucial for maintaining consistent sizing in apparel manufacturing.

What is Pre-Shrinking?

Pre-shrinking is a textile treatment process that reduces fabric shrinkage before cutting and sewing, ensuring garments maintain their size and fit after washing. This method involves washing or steaming fabric under controlled conditions to stabilize fibers, preventing unexpected shrinkage in finished products. Understanding pre-shrinking helps you choose durable clothing that retains shape and improves overall garment quality.

The Sanforizing Process Explained

The Sanforizing process involves stretching, shrinking, and fixing fabric through a controlled compressive shrinkage method that stabilizes the material to minimize future shrinkage. This precise mechanical treatment uses a steam-heated cylinder and a rubber belt to accurately compress the fabric, ensuring consistent dimensions and improved durability. When choosing fabrics for your garments, understanding Sanforizing ensures better fit retention and reduces the need for post-purchase alterations.

Key Differences Between Pre-Shrinking and Sanforizing

Pre-shrinking involves washing and drying fabrics before garment construction to reduce shrinkage, whereas sanforizing is a mechanical process that compresses and stabilizes fabric fibers to minimize shrinkage during subsequent washes. Sanforizing provides a more consistent and permanent dimensional stability compared to pre-shrinking, which can vary depending on fabric type and washing conditions. Fabric treated with sanforizing retains its size better, making it a preferred method in textile manufacturing for cotton and denim products.

Advantages of Pre-Shrinking

Pre-shrinking offers the advantage of consistent fabric dimensions before garment production, reducing post-production shrinkage anomalies and ensuring better fit accuracy. It enhances dimensional stability, minimizing fabric distortion and improving overall garment quality and durability. This process saves manufacturers from costly adjustments and rework caused by uneven shrinkage in later stages.

Benefits of Sanforizing for Fabrics

Sanforizing ensures fabrics retain their shape and size after washing, significantly reducing shrinkage compared to traditional pre-shrinking methods. This process improves fabric durability and provides a consistent fit, making garments more reliable for your everyday wear. Enhanced color retention and smoother texture are additional benefits, contributing to higher quality and longer-lasting fabric performance.

Applications in Textile and Apparel Industry

Pre-shrinking and Sanforizing are essential techniques in the textile and apparel industry to control fabric dimensional stability. Pre-shrinking involves washing or steaming fabrics before cutting and sewing to reduce shrinkage after garment manufacture, commonly applied in cotton and wool textiles. Sanforizing, a controlled mechanical compression process, is widely used for cotton, denim, and synthetic blends to ensure minimal shrinkage, improving product quality and customer satisfaction.

Impact on Fabric Quality and Longevity

Pre-shrinking and sanforizing both enhance fabric quality by stabilizing dimensions and preventing excessive shrinkage during washing. Sanforizing involves mechanical stretching and compressing, resulting in superior dimensional stability and improved fabric longevity compared to traditional pre-shrinking methods. Fabrics treated with sanforizing demonstrate enhanced durability, reduced distortion, and maintain their original appearance longer, contributing to better garment performance over time.

Choosing the Right Shrink-Resistant Treatment

Choosing the right shrink-resistant treatment involves understanding the differences between pre-shrinking and sanforizing processes. Pre-shrinking typically refers to washing or steam-treating fabric to minimize shrinkage before cutting and sewing, while sanforizing is a controlled mechanical process that permanently stabilizes fabric dimensions. Your decision should consider fabric type, desired durability, and production scale to ensure optimal shrink resistance and garment quality.

Conclusion: Pre-Shrinking vs Sanforizing

Pre-shrinking fabric involves washing and drying to minimize shrinkage before garment construction, ensuring size stability but requiring more labor and time. Sanforizing is a controlled mechanical process that compresses the fabric, providing consistent shrinkage control with higher efficiency and scalability in production. Sanforizing is generally preferred in mass manufacturing due to its reliability and cost-effectiveness, whereas pre-shrinking suits smaller-scale or specialty fabric treatments.

Pre-Shrinking vs Sanforizing Infographic

libmatt.com

libmatt.com