CMT (Cut, Make, Trim) refers to a manufacturing process where the factory only cuts, sews, and trims garments based on your provided materials, giving you control over fabric sourcing and design. FOB (Free on Board) includes the entire production process and shipping costs, meaning the supplier handles fabric procurement, manufacturing, and delivery to the port, simplifying your logistics but often at a higher price.

Table of Comparison

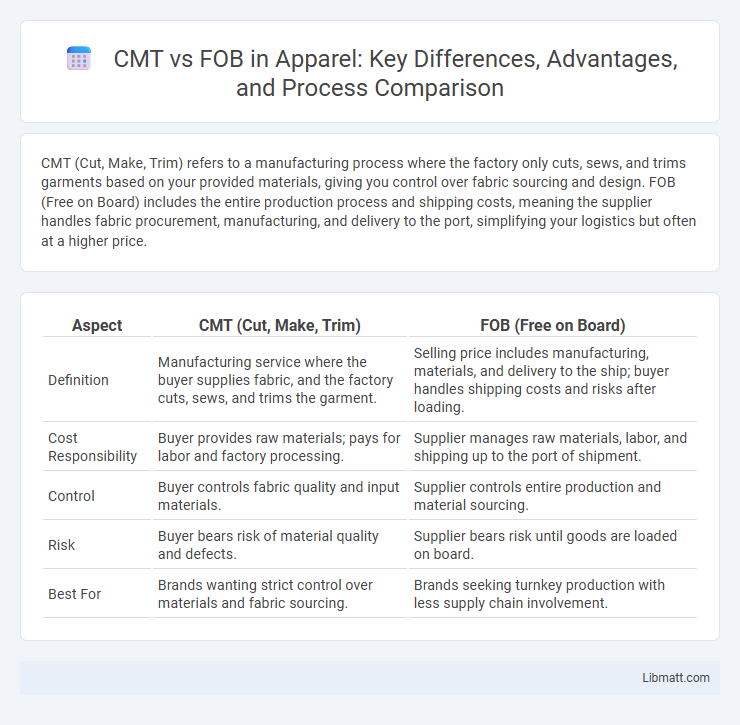

| Aspect | CMT (Cut, Make, Trim) | FOB (Free on Board) |

|---|---|---|

| Definition | Manufacturing service where the buyer supplies fabric, and the factory cuts, sews, and trims the garment. | Selling price includes manufacturing, materials, and delivery to the ship; buyer handles shipping costs and risks after loading. |

| Cost Responsibility | Buyer provides raw materials; pays for labor and factory processing. | Supplier manages raw materials, labor, and shipping up to the port of shipment. |

| Control | Buyer controls fabric quality and input materials. | Supplier controls entire production and material sourcing. |

| Risk | Buyer bears risk of material quality and defects. | Supplier bears risk until goods are loaded on board. |

| Best For | Brands wanting strict control over materials and fabric sourcing. | Brands seeking turnkey production with less supply chain involvement. |

Understanding CMT and FOB: Definitions

CMT (Cut, Make, Trim) refers to a garment manufacturing process where the buyer supplies materials and the manufacturer handles cutting, sewing, and trimming. FOB (Free On Board) indicates that the seller is responsible for delivering goods onto a shipping vessel, with costs and risks transferring to the buyer at the port of shipment. Understanding these definitions helps you make informed decisions in apparel sourcing and logistics.

Key Differences Between CMT and FOB

CMT (Cut, Make, Trim) involves the buyer supplying raw materials and the manufacturer providing labor and factory overhead to produce garments, while FOB (Free On Board) includes the manufacturer delivering finished goods with materials and assumes responsibility for shipment costs. CMT is commonly used when buyers want more control over fabric selection and quality, whereas FOB offers a turnkey solution where suppliers handle sourcing, production, and logistics. The cost structure differs as CMT pricing is based on labor and services only, whereas FOB pricing incorporates fabric costs, manufacturing, and freight charges.

Cost Structure: CMT vs FOB

CMT (Cut, Make, Trim) cost structure primarily involves expenses related to garment production, including labor and materials, while buyers supply the raw materials. FOB (Free on Board) cost structure includes not only CMT costs but also the sourcing of raw materials, shipping, and export duties, offering a more comprehensive pricing model. Your choice between CMT and FOB impacts your control over material quality and overall supply chain expenses.

Pros and Cons of CMT

CMT (Cut, Make, Trim) offers cost savings by allowing brands to control fabric sourcing and focus on manufacturing, enhancing customization and flexibility in production. However, the cons include higher logistical complexity and potential delays due to separate fabric procurement and possible lower negotiation power with manufacturers. Brands must weigh these trade-offs against FOB (Free on Board), where manufacturers handle fabric sourcing, providing streamlined processes but less control over material quality and cost.

Pros and Cons of FOB

FOB (Free on Board) terms transfer responsibility and risk to the buyer once the goods are loaded onto the shipping vessel, giving you greater control over shipping and insurance decisions. The main advantage of FOB is that it often reduces costs by allowing you to choose your preferred freight forwarder and negotiate rates directly, but it also requires more logistics management and expertise on your part. A downside includes potential delays or complications if you are not familiar with the shipping process, as the seller's responsibility ends at the port of origin.

Suitability: Which Buyers Should Choose CMT?

Buyers who require extensive control over the production process and prefer to manage fabric sourcing and design specifications should choose CMT (Cut, Make, Trim) as it allows them to customize materials and oversee quality closely. This model suits brands aiming for high flexibility, cost management, and differentiation through unique fabrics and trims. Retailers leaning towards complete outsourcing of materials and production often find FOB (Free on Board) more convenient, but buyers focused on product uniqueness and supply chain transparency benefit most from CMT.

Suitability: Which Buyers Should Choose FOB?

FOB (Free On Board) is suitable for buyers who prefer greater control over shipping logistics and costs, including selecting carriers and negotiating freight rates directly. Buyers with sufficient expertise in international shipping and customs procedures benefit from FOB as it allows them to manage and optimize the supply chain process. You should choose FOB if you want to oversee transportation risks and have the capacity to handle import documentation independently.

Case Study: CMT vs FOB in Apparel Manufacturing

The case study comparing CMT (Cut, Make, Trim) vs FOB (Free on Board) in apparel manufacturing highlights significant cost and control differences. In CMT, you provide the fabric and manage design, allowing lower production costs but requiring more oversight, while FOB suppliers handle sourcing and production end-to-end, often leading to higher pricing but streamlined processes. Choosing between CMT and FOB impacts your supply chain flexibility, cost management, and quality control depending on whether you prioritize in-house material control or outsourcing production responsibilities.

Quality Control in CMT and FOB Models

Quality control in CMT (Cut, Make, Trim) focuses primarily on inspecting the finishing processes such as stitching, trimming, and final assembly conducted by the manufacturer, with the buyer often overseeing fabric selection and pre-production quality checks. In FOB (Free On Board) model, quality control is comprehensive, covering raw material inspection, in-line production monitoring, and final product evaluation before shipment, as the supplier manages the entire production process. Effective quality control in FOB ensures consistent product standards and reduces defects, while in CMT, the responsibility is shared between buyer and manufacturer, sometimes leading to variations in quality oversight.

How to Decide Between CMT and FOB

Deciding between CMT (Cut, Make, Trim) and FOB (Free on Board) depends on your desired level of control over manufacturing and logistics. Choose CMT when you want to manage fabric sourcing and focus solely on garment assembly, reducing risks related to material quality and cost fluctuations. Opt for FOB to outsource entire production, including materials and shipping, benefiting from supplier responsibility and simplified supply chain management.

CMT vs FOB Infographic

libmatt.com

libmatt.com