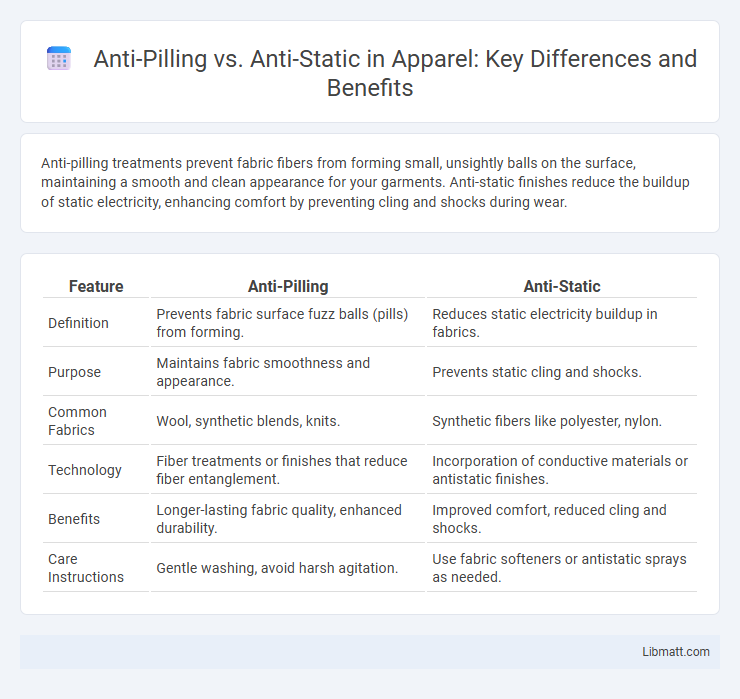

Anti-pilling treatments prevent fabric fibers from forming small, unsightly balls on the surface, maintaining a smooth and clean appearance for your garments. Anti-static finishes reduce the buildup of static electricity, enhancing comfort by preventing cling and shocks during wear.

Table of Comparison

| Feature | Anti-Pilling | Anti-Static |

|---|---|---|

| Definition | Prevents fabric surface fuzz balls (pills) from forming. | Reduces static electricity buildup in fabrics. |

| Purpose | Maintains fabric smoothness and appearance. | Prevents static cling and shocks. |

| Common Fabrics | Wool, synthetic blends, knits. | Synthetic fibers like polyester, nylon. |

| Technology | Fiber treatments or finishes that reduce fiber entanglement. | Incorporation of conductive materials or antistatic finishes. |

| Benefits | Longer-lasting fabric quality, enhanced durability. | Improved comfort, reduced cling and shocks. |

| Care Instructions | Gentle washing, avoid harsh agitation. | Use fabric softeners or antistatic sprays as needed. |

Understanding Anti-Pilling and Anti-Static: Key Definitions

Anti-pilling refers to the fabric's ability to resist the formation of small fiber balls or "pills" on the surface caused by friction, enhancing durability and maintaining a smooth appearance. Anti-static treatments reduce the accumulation of static electricity, preventing cling and minimizing discomfort associated with static shocks in synthetic and natural fibers. Understanding these distinctions is essential for selecting textiles that offer both long-lasting wear and improved comfort in various applications.

How Anti-Pilling Works: Mechanisms and Benefits

Anti-pilling fabric treatments function by strengthening fiber surfaces and reducing friction, which prevents loose fibers from tangling and forming small balls on the fabric. These treatments typically involve chemical finishes or fiber blending techniques designed to maintain fabric smoothness and extend garment lifespan. The benefits include enhanced fabric appearance, improved comfort, and prolonged durability, making garments look newer for longer periods.

The Science Behind Anti-Static Fabrics

Anti-static fabrics are engineered through the integration of conductive fibers such as carbon or metallic threads, which dissipate electrical charges and prevent static build-up. Unlike anti-pilling treatments that focus on fabric surface integrity by reducing fiber fuzz and entanglement, anti-static technology addresses the electrostatic properties at the molecular level. This scientific approach enhances wearer comfort and safety by minimizing static shocks and static cling in synthetic textiles.

Comparing Anti-Pilling vs Anti-Static: What’s the Difference?

Anti-pilling treatments prevent fabric fibers from forming small, unsightly balls on the surface, enhancing the durability and appearance of your garments by maintaining a smooth texture. Anti-static treatments reduce the buildup of static electricity on fabrics, minimizing cling and discomfort caused by static shocks, especially in synthetic materials. Understanding the difference helps you choose fabrics that suit your needs, whether you prioritize long-lasting smoothness or static-free comfort.

Material Types Commonly Treated with Anti-Pilling and Anti-Static

Materials commonly treated with anti-pilling technology include synthetic fibers like polyester and nylon, as well as cotton blends, to enhance fabric durability and maintain a smooth surface. Anti-static treatments are frequently applied to synthetic materials such as polyester, acrylic, and nylon to reduce static electricity buildup and improve comfort and safety in apparel and upholstery. Both treatments are vital in textiles used for activewear, workwear, and home furnishings to improve longevity and user experience.

Performance and Durability: Anti-Pilling vs Anti-Static

Anti-pilling fabrics resist the formation of small fiber balls, ensuring long-lasting wear and a smooth appearance, which enhances Your garment's durability. Anti-static materials prevent the buildup of static electricity, improving comfort and reducing cling without necessarily impacting fabric strength. Performance differences between anti-pilling and anti-static treatments highlight their unique advantages in maintaining fabric quality and user comfort over time.

Applications in Apparel: Which Is More Important?

In apparel applications, anti-pilling treatments are crucial for maintaining fabric appearance and longevity, especially in everyday wear like sweaters and activewear where friction causes fabric fuzz and pills. Anti-static properties are essential in environments sensitive to static buildup such as healthcare uniforms and performance wear, reducing discomfort and preventing sparks. Prioritizing depends on the garment's intended use; anti-pilling is more important for durability in casual and high-friction clothing, while anti-static is critical in specialized or technical apparel.

Care Instructions for Anti-Pilling and Anti-Static Fabrics

Care instructions for anti-pilling fabrics emphasize gentle washing in cold water and avoiding high heat drying to preserve fiber integrity and reduce surface fuzzing. Anti-static fabrics require laundering with fabric softeners or anti-static sprays to prevent static buildup, and tumble drying on low heat helps maintain their static-resistant properties. Both fabric types benefit from avoiding harsh chemicals and abrasive washing cycles to extend their lifespan and performance.

Innovations and Trends in Anti-Pilling and Anti-Static Technology

Innovations in anti-pilling technology emphasize advanced fiber treatments and coating applications that enhance fabric durability and maintain fabric softness over time, with nanotechnology playing a significant role in reducing fiber abrasion. Recent trends in anti-static technology focus on integrating conductive polymers and carbon-based additives to dissipate static charges efficiently, enhancing user comfort and safety in synthetic textiles. The convergence of smart textiles and eco-friendly processes is driving the development of multifunctional fabrics that combine anti-pilling and anti-static properties for superior performance in apparel and technical fabrics.

Choosing the Right Fabric: Anti-Pilling, Anti-Static, or Both?

Selecting the right fabric depends on your specific needs: anti-pilling fabrics resist the formation of unsightly fuzz balls, maintaining a smooth and polished appearance over time, while anti-static fabrics prevent static electricity buildup that can cause discomfort and attract dust. For garments worn frequently or in dry environments, fabrics with both anti-pilling and anti-static properties offer optimal durability and comfort, ensuring your clothing looks fresh and feels comfortable throughout the day. Understanding the fabric composition and treatment methods helps you make an informed choice that enhances the longevity and performance of your wardrobe.

anti-pilling vs anti-static Infographic

libmatt.com

libmatt.com