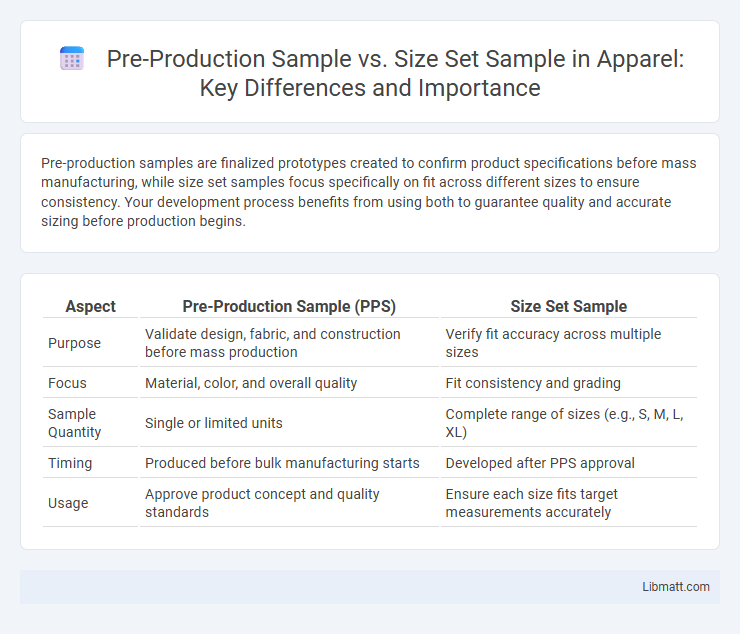

Pre-production samples are finalized prototypes created to confirm product specifications before mass manufacturing, while size set samples focus specifically on fit across different sizes to ensure consistency. Your development process benefits from using both to guarantee quality and accurate sizing before production begins.

Table of Comparison

| Aspect | Pre-Production Sample (PPS) | Size Set Sample |

|---|---|---|

| Purpose | Validate design, fabric, and construction before mass production | Verify fit accuracy across multiple sizes |

| Focus | Material, color, and overall quality | Fit consistency and grading |

| Sample Quantity | Single or limited units | Complete range of sizes (e.g., S, M, L, XL) |

| Timing | Produced before bulk manufacturing starts | Developed after PPS approval |

| Usage | Approve product concept and quality standards | Ensure each size fits target measurements accurately |

Introduction to Garment Sampling in Fashion Manufacturing

Garment sampling in fashion manufacturing includes Pre-Production Samples (PPS) and Size Set Samples, each serving distinct purposes to ensure quality and fit. Pre-Production Samples are detailed prototypes that reflect the final design and materials, allowing you to assess overall aesthetics and construction before bulk production. Size Set Samples focus on grading accuracy and fit across various sizes, ensuring consistent sizing and comfort for different body types.

Definition of Pre-Production Sample (PPS)

A Pre-Production Sample (PPS) is a prototype garment created to finalize the design, fabric, and construction details before mass production begins. It serves as a quality benchmark to check fit, color, and overall workmanship, ensuring alignment with buyer specifications. PPS helps identify and resolve potential issues early, reducing production errors and minimizing costly revisions.

Definition of Size Set Sample

A Size Set Sample is a collection of pre-production garments representing the full range of sizes for a particular style, used to evaluate fit, proportion, and consistency before mass production. This sample helps identify necessary adjustments to ensure each size meets quality and fit standards, reducing costly errors in the final product. Your production process benefits from clear benchmarks established by Size Set Samples, streamlining approvals and ensuring better sizing accuracy.

Key Purposes of Pre-Production Sample

Pre-Production Samples serve as crucial prototypes to verify design accuracy, fabric quality, and fit before full-scale manufacturing begins, ensuring alignment with brand standards. They help identify potential production issues, enabling necessary adjustments to minimize costly errors and delays. This step is vital for confirming critical details such as stitching, color consistency, and trim placement to maintain product integrity.

Key Purposes of Size Set Sample

Size set samples serve as a critical step in quality assurance, allowing precise evaluation of fit, fabric consistency, and overall garment construction across multiple sizes before mass production. They provide manufacturers and designers the opportunity to identify and correct sizing issues, ensuring your final products meet exact specifications and customer expectations. This process minimizes costly errors and improves production efficiency by confirming that the grading between sizes maintains proportional accuracy.

Differences Between Pre-Production and Size Set Samples

Pre-Production Sample (PPS) is a final prototype created to ensure that all design, material, and production processes meet the intended quality before mass manufacturing begins, while a Size Set Sample focuses on verifying the fit and grading consistency across different sizes. PPS involves thorough quality checks and is typically produced using production-line materials and techniques, whereas Size Set Samples are smaller groups of samples used primarily for fit approval and size accuracy. Your decision between these depends on whether you need comprehensive quality assurance or validation of sizing specifications.

When and Why Each Sample Is Used in Production

Pre-Production Samples (PPS) are created early in the manufacturing process to verify design accuracy, fabric quality, and overall product specifications before mass production begins. Size Set Samples are produced after the PPS and are essential for checking fit and consistency across all sizes, ensuring your clothing or product meets size standards for diverse customers. Using PPS helps avoid costly production errors, while Size Set Samples confirm that every size maintains proper fit and quality throughout the product line.

Common Issues Detected with Each Sample Type

Pre-Production Samples often reveal fabric defects, color inconsistencies, and construction errors that affect final product quality, while Size Set Samples commonly identify fit issues, grading problems, and proportion mismatches across different sizes. Both sample types help prevent costly production delays by allowing early detection of design flaws and performance problems. Detecting these issues at the respective sample stages ensures smoother mass production and improved garment consistency.

Importance of Both Samples for Quality Assurance

Pre-Production Sample and Size Set Sample play crucial roles in quality assurance by ensuring product consistency and fit accuracy before mass production. The Pre-Production Sample allows you to verify design details, materials, and construction techniques, preventing costly defects and revisions. Size Set Samples provide a comprehensive check on sizing across all intended measurements, ensuring your products meet customer expectations and reduce returns.

Best Practices for Managing Sampling in Apparel Production

Pre-Production Sample (PPS) ensures the garment meets design specifications and fabric quality before bulk manufacturing, while the Size Set Sample verifies fit accurately across the size range based on standardized measurement charts. Best practices for managing sampling in apparel production include clear communication of technical packs, timely approval processes, and iterative feedback loops between designers and manufacturers to reduce errors and minimize delays. Tracking both PPS and Size Set samples systematically through digital platforms enhances collaboration and accelerates decision-making, ensuring final production aligns with quality and fit expectations.

Pre-Production Sample vs Size Set Sample Infographic

libmatt.com

libmatt.com