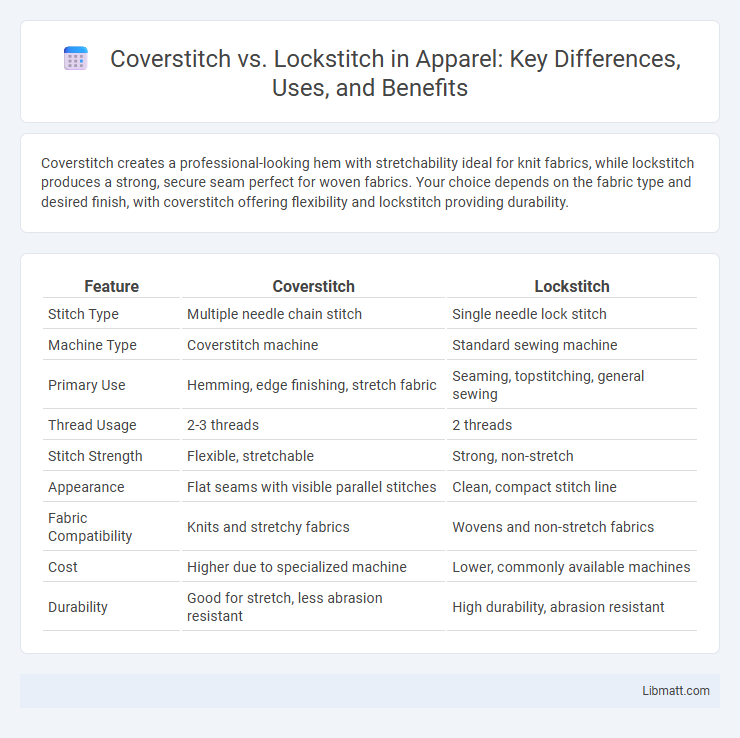

Coverstitch creates a professional-looking hem with stretchability ideal for knit fabrics, while lockstitch produces a strong, secure seam perfect for woven fabrics. Your choice depends on the fabric type and desired finish, with coverstitch offering flexibility and lockstitch providing durability.

Table of Comparison

| Feature | Coverstitch | Lockstitch |

|---|---|---|

| Stitch Type | Multiple needle chain stitch | Single needle lock stitch |

| Machine Type | Coverstitch machine | Standard sewing machine |

| Primary Use | Hemming, edge finishing, stretch fabric | Seaming, topstitching, general sewing |

| Thread Usage | 2-3 threads | 2 threads |

| Stitch Strength | Flexible, stretchable | Strong, non-stretch |

| Appearance | Flat seams with visible parallel stitches | Clean, compact stitch line |

| Fabric Compatibility | Knits and stretchy fabrics | Wovens and non-stretch fabrics |

| Cost | Higher due to specialized machine | Lower, commonly available machines |

| Durability | Good for stretch, less abrasion resistant | High durability, abrasion resistant |

Introduction to Coverstitch and Lockstitch

Coverstitch and lockstitch are two fundamental types of sewing stitches used in garment construction and fabric finishing. The lockstitch, created by interlocking upper and lower threads, is commonly employed for strong, durable seams in various fabrics, offering a clean finish on both sides. Coverstitch, typically produced by specialized machines with multiple needles and loopers, is ideal for hemming stretch fabrics, providing flexibility and a professional, double-needle appearance on the garment exterior.

What is a Coverstitch Machine?

A coverstitch machine is a specialized sewing machine designed to create professional hems and seams, primarily on knit fabrics, by producing a strong, flexible stitch that covers the raw edge with multiple parallel needle threads and a looper thread underneath. Unlike a lockstitch machine, which forms a single stitch by interlocking upper and lower threads to create a durable seam on woven fabrics, a coverstitch machine excels in stretchability and durability, making it ideal for finishing garment edges. This machine typically features two or three needles and a looper mechanism, allowing for wide or narrow coverstitches that provide both elasticity and a clean, decorative look on activewear, t-shirts, and lingerie.

Understanding the Lockstitch Machine

The lockstitch machine creates a strong, durable seam by interlocking two threads--one from the needle and another from the bobbin--forming a stitch that lies flat and resists unraveling. Understanding the lockstitch machine's mechanism is essential for sewing projects requiring professional finishes and high tensile strength. Your choice of lockstitch machines impacts garment quality, ensuring neat, secure seams ideal for woven fabrics.

Key Differences Between Coverstitch and Lockstitch

Coverstitch and lockstitch differ primarily in stitch structure and application, where coverstitch creates parallel rows of stitching ideal for hemming and stretch fabrics, while lockstitch forms interlocking stitches providing strong, versatile seams for various materials. The coverstitch uses multiple needles and a looper thread, producing a professional finish on knitwear, whereas the lockstitch employs a bobbin and needle thread locking together for durability and neat appearance on woven fabrics. Understanding these key differences helps you choose the right stitch type for your sewing projects, ensuring optimal garment performance and finish.

Applications and Sewing Uses

Coverstitch is ideal for hemming knit fabrics, activewear, and stretch materials, providing a flexible and durable finish that prevents fabric distortion. Lockstitch is widely used for sewing woven fabrics, garment construction, and topstitching, offering a strong, neat, and secure seam suitable for a variety of sewing projects. Coverstitch excels in creating professional-looking hems and seams on stretchy fabrics, while lockstitch delivers precise and stable stitching for non-stretch materials.

Pros and Cons of Coverstitch

Coverstitch machines excel in creating professional hems and stretchy seams, offering superior fabric flexibility and durability compared to lockstitch machines, which are better suited for standard seams and topstitching. The main advantages of coverstitch include its ability to produce clean, flat seams ideal for knit fabrics, while its cons involve limited stitch variety and typically higher machine costs. Coverstitch is less versatile than lockstitch for heavy-duty or intricate sewing tasks but provides optimal finish quality for athletic wear and casual garments.

Pros and Cons of Lockstitch

Lockstitch machines are praised for producing strong, durable seams with a clean, professional appearance, ideal for garment construction and topstitching. However, the lockstitch requires bobbin thread management, which can slow down sewing and increase thread breaks compared to coverstitch machines. Your choice depends on whether you prioritize stitch strength and neatness (lockstitch) or stretchability and speed (coverstitch).

Which Stitch is Best for Your Project?

Coverstitch provides excellent stretch and durability, making it ideal for hemming knits and activewear. Lockstitch offers a strong, precise seam perfect for woven fabrics and general garment construction. Choosing between coverstitch and lockstitch depends on fabric type and desired finish; coverstitch excels in stretchability while lockstitch ensures stable, secure seams.

Tips for Choosing the Right Sewing Machine

Choosing the right sewing machine depends on the type of stitching you need: coverstitch machines are ideal for hemming stretch fabrics and creating professional-looking seams on knits, while lockstitch machines excel at strong, permanent seams for woven fabrics. Consider your project requirements, fabric types, and desired stitch versatility--coverstitch machines often offer multiple needle options and chainstitch functionality, whereas lockstitch machines focus on precise single-thread stitches. Evaluate machine features such as stitch length, speed control, and ease of threading to ensure optimal performance tailored to your sewing needs.

Conclusion: Coverstitch vs. Lockstitch Overview

Coverstitch and lockstitch serve distinct purposes: coverstitch excels in hemming, creating stretchable seams ideal for knit fabrics, while lockstitch provides strong, non-stretch seams suited for woven fabrics and general sewing. The coverstitch features multiple needles and a looper thread for durable, professional hems, whereas the lockstitch uses two threads intertwined for precise, secure stitching. Choosing between coverstitch vs lockstitch depends on fabric type and project needs, with coverstitch favored for garment finishing and lockstitch preferred for structural seams.

Coverstitch vs lockstitch Infographic

libmatt.com

libmatt.com