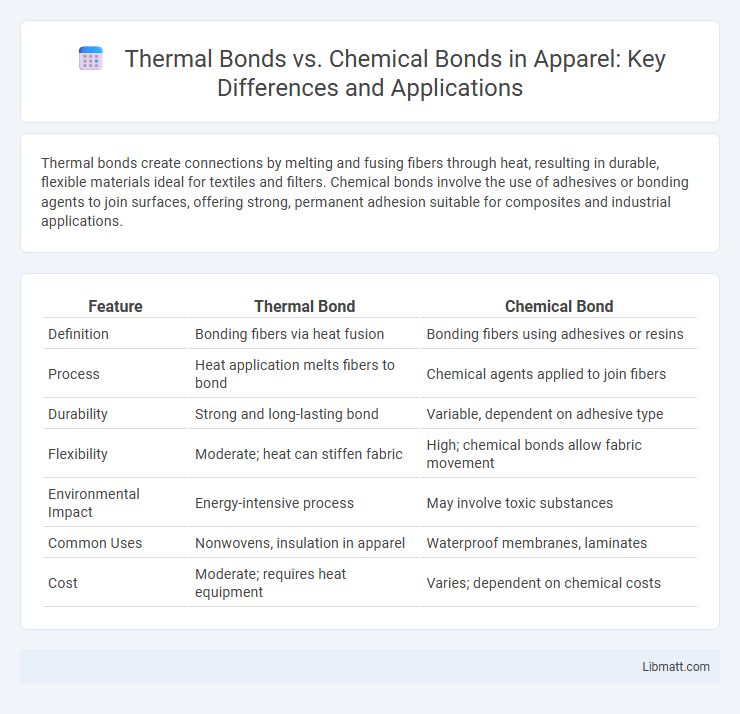

Thermal bonds create connections by melting and fusing fibers through heat, resulting in durable, flexible materials ideal for textiles and filters. Chemical bonds involve the use of adhesives or bonding agents to join surfaces, offering strong, permanent adhesion suitable for composites and industrial applications.

Table of Comparison

| Feature | Thermal Bond | Chemical Bond |

|---|---|---|

| Definition | Bonding fibers via heat fusion | Bonding fibers using adhesives or resins |

| Process | Heat application melts fibers to bond | Chemical agents applied to join fibers |

| Durability | Strong and long-lasting bond | Variable, dependent on adhesive type |

| Flexibility | Moderate; heat can stiffen fabric | High; chemical bonds allow fabric movement |

| Environmental Impact | Energy-intensive process | May involve toxic substances |

| Common Uses | Nonwovens, insulation in apparel | Waterproof membranes, laminates |

| Cost | Moderate; requires heat equipment | Varies; dependent on chemical costs |

Introduction to Bonding Mechanisms

Thermal bonds form through heat-induced physical interactions where materials fuse without altering their chemical structures, commonly seen in processes like thermal welding or heat pressing. Chemical bonds involve the sharing or transfer of electrons between atoms, creating new substances with distinct molecular structures, as exemplified by covalent or ionic bonding. Understanding these bonding mechanisms is crucial in material science to optimize manufacturing techniques and tailor material properties for specific applications.

What is a Thermal Bond?

A thermal bond is a type of physical connection formed when heat causes materials, typically fibers or polymers, to soften and fuse together without altering their chemical structures. This process relies on temperature control to create strong, durable bonds primarily used in textiles, composites, and packaging industries. Unlike chemical bonds, thermal bonds do not involve electron sharing or transfer, preserving the original molecular integrity of bonded materials.

What is a Chemical Bond?

A chemical bond is the force that holds atoms together in molecules or compounds through the sharing or transfer of electrons, enabling the formation of stable structures. Unlike thermal bonds, which involve physical adhesion through heat-induced melting and solidification, chemical bonds establish strong interactions at the atomic level, including ionic, covalent, and metallic bonds. These bonds determine the chemical properties and reactivity of substances by altering electron configurations and atomic relationships.

Key Differences Between Thermal and Chemical Bonds

Thermal bonds rely on heat to fuse materials by softening or melting their surfaces, creating a physical attachment without altering the material's chemical composition. Chemical bonds form through electron sharing or transfer between atoms, resulting in new substances with distinct chemical properties. Your choice between thermal and chemical bonding depends on factors like desired bond strength, material compatibility, and application requirements.

Advantages of Thermal Bonding

Thermal bonding offers significant advantages such as creating strong, durable connections without the use of adhesives or chemicals, which minimizes environmental impact and potential toxicity. This method enhances material compatibility and maintains structural integrity under various stress conditions by using heat to fuse surfaces at a molecular level. Your projects benefit from faster processing times and improved bond consistency compared to chemical bonding techniques.

Advantages of Chemical Bonding

Chemical bonding offers superior strength and durability compared to thermal bonding, creating more stable and long-lasting connections at the molecular level. This method enables precise control over material properties, enhancing resistance to heat, moisture, and mechanical stress. Your projects benefit from improved performance and reliability due to the robust nature of chemical bonds.

Applications of Thermal Bonding

Thermal bonding is widely used in industries such as textiles, automotive, and packaging to create strong, durable joins without the need for adhesives or solvents. Your products can benefit from thermal bonding techniques, which offer eco-friendly solutions by using heat and pressure to fuse materials, thus enhancing production efficiency and environmental sustainability. This method is ideal for applications requiring clean, precise bonds, such as nonwoven fabrics and composite materials.

Applications of Chemical Bonding

Chemical bonding plays a crucial role in various applications such as pharmaceuticals, where molecular interactions determine drug efficacy and stability. In materials science, chemical bonds influence the creation of polymers and composites with enhanced mechanical properties and durability. Your understanding of chemical bonding can improve innovations in catalysis, enabling more efficient chemical reactions and energy conversions.

Factors to Consider When Choosing a Bonding Method

Thermal bonds require careful consideration of temperature tolerance and material compatibility, ensuring that heat application does not degrade or deform the substrates. Chemical bonds depend on the adhesive's chemical properties and curing conditions, making factors like solvent resistance, bonding strength, and environmental exposure critical for selection. Material type, application environment, and desired bond durability primarily influence the choice between thermal and chemical bonding methods.

Future Trends in Bonding Technologies

Thermal bonds are increasingly favored in future bonding technologies for their eco-friendly and energy-efficient processes, reducing dependency on harmful adhesives used in chemical bonds. Advances in ultrasonic and infrared thermal bonding improve precision and durability, making them ideal for electronics and medical device manufacturing. Your choice of bonding technology will benefit from these innovations as industries prioritize sustainability, strength, and faster production times.

Thermal bond vs chemical bond Infographic

libmatt.com

libmatt.com