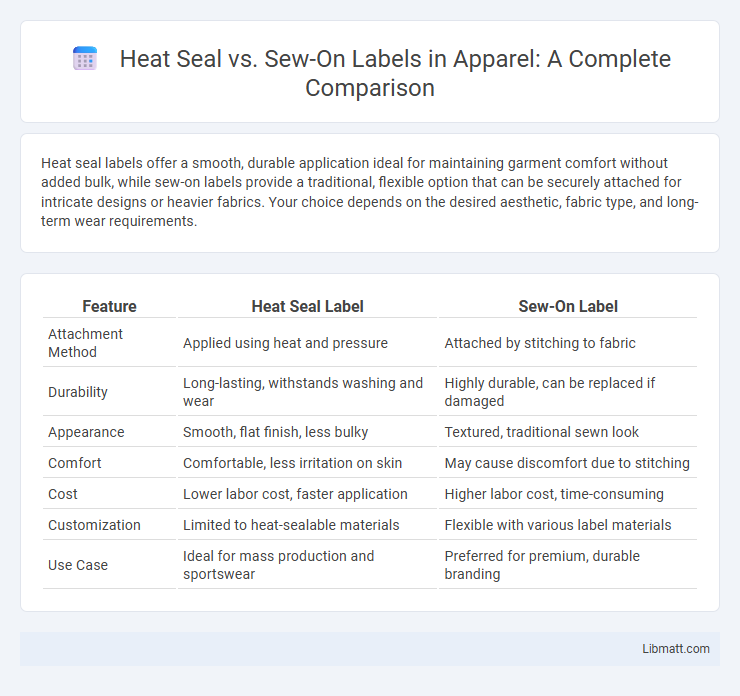

Heat seal labels offer a smooth, durable application ideal for maintaining garment comfort without added bulk, while sew-on labels provide a traditional, flexible option that can be securely attached for intricate designs or heavier fabrics. Your choice depends on the desired aesthetic, fabric type, and long-term wear requirements.

Table of Comparison

| Feature | Heat Seal Label | Sew-On Label |

|---|---|---|

| Attachment Method | Applied using heat and pressure | Attached by stitching to fabric |

| Durability | Long-lasting, withstands washing and wear | Highly durable, can be replaced if damaged |

| Appearance | Smooth, flat finish, less bulky | Textured, traditional sewn look |

| Comfort | Comfortable, less irritation on skin | May cause discomfort due to stitching |

| Cost | Lower labor cost, faster application | Higher labor cost, time-consuming |

| Customization | Limited to heat-sealable materials | Flexible with various label materials |

| Use Case | Ideal for mass production and sportswear | Preferred for premium, durable branding |

Introduction to Garment Labeling Methods

Heat seal and sew-on labels represent two common garment labeling methods, each offering distinct advantages. Heat seal labels use heat and pressure to bond the label directly to the fabric, providing a smooth, irritation-free finish ideal for activewear. Sew-on labels, stitched into the garment, offer durability and traditional appeal, making them preferred for high-end or thick fabric items. Your choice depends on fabric type, comfort requirements, and brand presentation priorities.

What Are Heat Seal Labels?

Heat seal labels are adhesive-free labels that bond directly to fabric using heat and pressure, creating a lightweight, flexible, and tamper-resistant attachment. These labels are popular in apparel and textile industries for their smooth feel and durability, as they do not add bulk or irritation to garments. Heat seal technology ensures the label remains securely affixed through multiple washes, providing a professional and long-lasting branding solution.

What Are Sew-On Labels?

Sew-on labels are textile tags attached to products through stitching, commonly used for clothing, accessories, and textiles to ensure durability and maintain appearance after repeated washing. These labels allow for detailed customization in size, color, and branding, offering a tactile and premium feel compared to heat seal labels. Their sewn-in design provides enhanced longevity and resistance to peeling, making them ideal for high-quality garments and items requiring long-term label retention.

Key Differences Between Heat Seal and Sew-On Labels

Heat seal labels bond directly to fabric using heat and pressure, offering a smooth, non-intrusive finish ideal for comfort and durability. Sew-on labels attach by stitching, providing added strength and traditional appearance, but may cause irritation due to raised edges. Your choice depends on the desired label permanence, fabric type, and comfort requirements.

Durability: Heat Seal vs Sew-On Labels

Heat seal labels offer superior durability by bonding directly to fabric fibers, ensuring resistance to washing, abrasion, and fading over time. Sew-on labels, while providing strong attachment through stitching, can fray at the edges and may detach with repeated laundering or heavy wear. Choosing heat seal labels enhances longevity for activewear and performance garments, whereas sew-on labels remain suitable for decorative or less intensive use.

Application Process and Time Efficiency

Heat seal labels attach quickly using heat and pressure, providing a uniform bond ideal for high-volume production, which significantly reduces application time compared to sewing. Sew-on labels require manual or machine stitching, making the process more time-consuming and labor-intensive but offering durability and flexibility for garments needing repositioning. Your choice depends on whether speed and efficiency or adjustability and strength are the primary concerns for your labeling needs.

Cost Comparison: Heat Seal vs Sew-On Labels

Heat seal labels typically offer a lower upfront cost due to simpler materials and faster application processes, making them ideal for large-volume production runs. Sew-on labels involve higher labor and material costs because of stitching requirements and durability considerations, which can increase overall expenses. Understanding your product's budget and production scale can help you choose the most cost-effective labeling method for your needs.

Best Uses for Heat Seal Labels

Heat seal labels are ideal for sportswear, activewear, and hygiene-sensitive garments because they provide a smooth, tagless finish that enhances comfort and reduces skin irritation. These labels bond directly to the fabric using heat and pressure, ensuring durability through multiple washes without peeling or fading. Your choice of heat seal labels supports lightweight clothing designs where a sleek, invisible branding solution is essential.

Best Uses for Sew-On Labels

Sew-on labels are ideal for garments requiring durability and frequent washing, such as uniforms, denim, and workwear, due to their secure attachment and resistance to wear. They provide a traditional, high-quality look favored in premium clothing lines, allowing for intricate embroidery or woven designs that withstand repeated laundering. These labels also enable easy customization and repositioning during garment production, making them suitable for brands prioritizing long-lasting brand identity.

Choosing the Right Labeling Method for Your Products

Heat seal labels offer a smooth, durable finish ideal for activewear and products requiring frequent washing, while sew-on labels provide a traditional, high-quality appearance with strong attachment suitable for heavy fabrics and long-term use. Your choice depends on product type, fabric sensitivity, and desired label durability; heat seals minimize irritation and are less likely to fray compared to sew-ons. Evaluating these factors ensures the labeling method enhances product value and customer satisfaction effectively.

Heat seal vs sew-on label Infographic

libmatt.com

libmatt.com