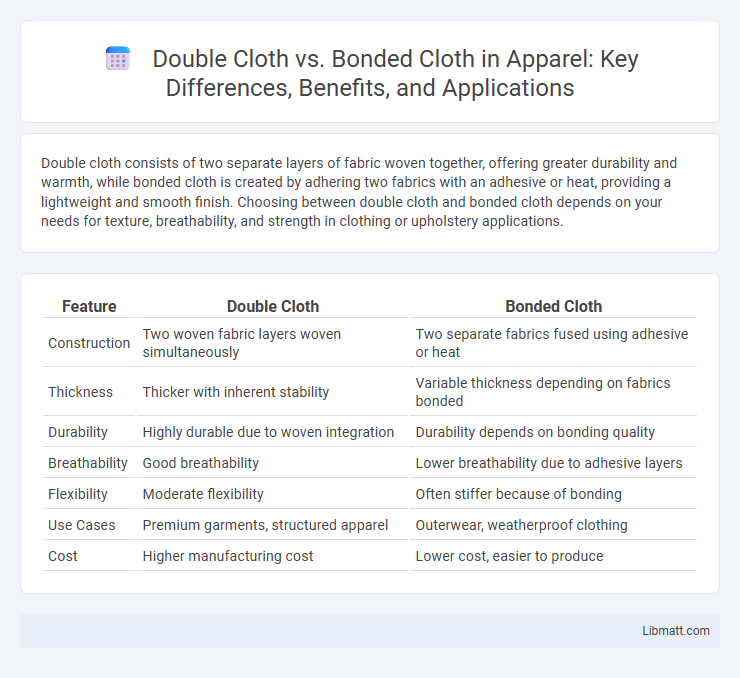

Double cloth consists of two separate layers of fabric woven together, offering greater durability and warmth, while bonded cloth is created by adhering two fabrics with an adhesive or heat, providing a lightweight and smooth finish. Choosing between double cloth and bonded cloth depends on your needs for texture, breathability, and strength in clothing or upholstery applications.

Table of Comparison

| Feature | Double Cloth | Bonded Cloth |

|---|---|---|

| Construction | Two woven fabric layers woven simultaneously | Two separate fabrics fused using adhesive or heat |

| Thickness | Thicker with inherent stability | Variable thickness depending on fabrics bonded |

| Durability | Highly durable due to woven integration | Durability depends on bonding quality |

| Breathability | Good breathability | Lower breathability due to adhesive layers |

| Flexibility | Moderate flexibility | Often stiffer because of bonding |

| Use Cases | Premium garments, structured apparel | Outerwear, weatherproof clothing |

| Cost | Higher manufacturing cost | Lower cost, easier to produce |

Introduction to Double Cloth and Bonded Cloth

Double cloth consists of two layers of fabric woven simultaneously on the loom, creating a thick, durable material with unique textures and reversible designs. Bonded cloth is made by chemically or mechanically fusing two separate fabric layers, resulting in a lightweight yet sturdy composite often used for enhanced insulation and water resistance. Both fabrics offer distinct advantages in apparel and upholstery, with double cloth excelling in texture complexity and bonded cloth in functional performance.

Defining Double Cloth

Double cloth consists of two separate layers of fabric woven simultaneously on the same loom, creating a thicker, reversible textile with enhanced insulation and durability. This construction differs from bonded cloth, which involves adhering two distinct fabric layers together using adhesives or heat rather than weaving. Double cloth's interlaced structure offers superior breathability and flexibility compared to the typically stiffer bonded fabrics.

Understanding Bonded Cloth

Bonded cloth consists of two layers of fabric fused together using adhesive or heat, providing enhanced durability and a smooth finish ideal for outerwear and technical garments. This fabric construction ensures improved insulation and wind resistance compared to double cloth, which is woven with interlocking threads creating a reversible texture. Understanding bonded cloth allows you to select materials optimized for strength, weather protection, and a sleek appearance in your apparel projects.

Key Differences in Construction

Double cloth consists of two woven layers connected by warp or weft yarns, creating a reversible fabric with distinct faces, while bonded cloth involves two separate fabric layers adhered with an adhesive or heat process without interlacing yarns. The construction of double cloth provides thickness, durability, and a textured appearance, whereas bonded cloth offers flexibility and enhanced stability but may lack breathability. Understanding these construction differences helps you choose the ideal fabric for applications requiring either structural integrity or lightweight performance.

Material Composition Comparison

Double cloth typically consists of two separate woven layers made from cotton, wool, silk, or blends that are interlaced to create a thick, reversible fabric with enhanced insulation properties. Bonded cloth features synthetic or natural fabrics, such as polyester or fleece, fused together using adhesives or thermal bonding to provide water resistance and durability. Material composition in double cloth emphasizes layered yarn structures, while bonded cloth relies on the adhesion of distinct textile surfaces for performance characteristics.

Performance and Durability

Double cloth exhibits superior durability due to its two-layered woven structure, which enhances resistance to wear, tear, and abrasion, making it ideal for high-performance applications such as upholstery and heavy-duty garments. Bonded cloth offers enhanced performance in water resistance and windproofing, achieved by laminating or bonding different fabric layers, but may be less flexible and prone to delamination under intense mechanical stress. Both textiles provide distinct advantages, with double cloth excelling in longevity and bonded cloth delivering specialized functional properties.

Applications and Uses

Double cloth fabric, known for its reversible design and thickness, is widely used in high-end apparel, upholstery, and winter wear due to its insulation properties and durability. Bonded cloth, created by fusing two layers with adhesives or heat, finds applications in sportswear, protective clothing, and industrial textiles because of its strength and resistance to wind and water. In automotive interiors and technical textiles, the choice between double cloth and bonded cloth depends on the required combination of comfort, structural integrity, and functional performance.

Advantages of Double Cloth

Double cloth offers superior warmth and durability due to its dual-layer construction, making it ideal for heavy-duty garments and upholstery. The fabric provides excellent insulation and breathability, enhancing comfort without added bulk. Its reversible nature allows for versatile design options, increasing aesthetic appeal and functional use.

Benefits of Bonded Cloth

Bonded cloth offers enhanced durability and water resistance compared to double cloth, making it ideal for outdoor apparel and technical fabrics. Its construction fuses two layers with a strong adhesive, providing superior windproofing and thermal insulation without added bulk. You benefit from improved performance in harsh weather conditions while maintaining lightweight flexibility.

Choosing Between Double Cloth and Bonded Cloth

Double cloth offers a layered textile structure with two woven fabrics interlinked, providing enhanced durability, insulation, and texture versatility ideal for tailored garments and upholstery. Bonded cloth involves fusing two fabric layers with adhesives or heat, creating a lightweight, stable material suited for outerwear and technical apparel requiring weather resistance. Selecting between double cloth and bonded cloth depends on the desired combination of comfort, strength, and application-specific features such as insulation or water repellency.

Double cloth vs bonded cloth Infographic

libmatt.com

libmatt.com