Ultrasonic cutting uses high-frequency vibrations to slice materials cleanly without generating heat, making it ideal for heat-sensitive fabrics and composites. Laser cutting, on the other hand, employs a focused beam of light to precisely cut or engrave materials, offering superior accuracy and the ability to handle complex designs, which can enhance your manufacturing process depending on the material and application.

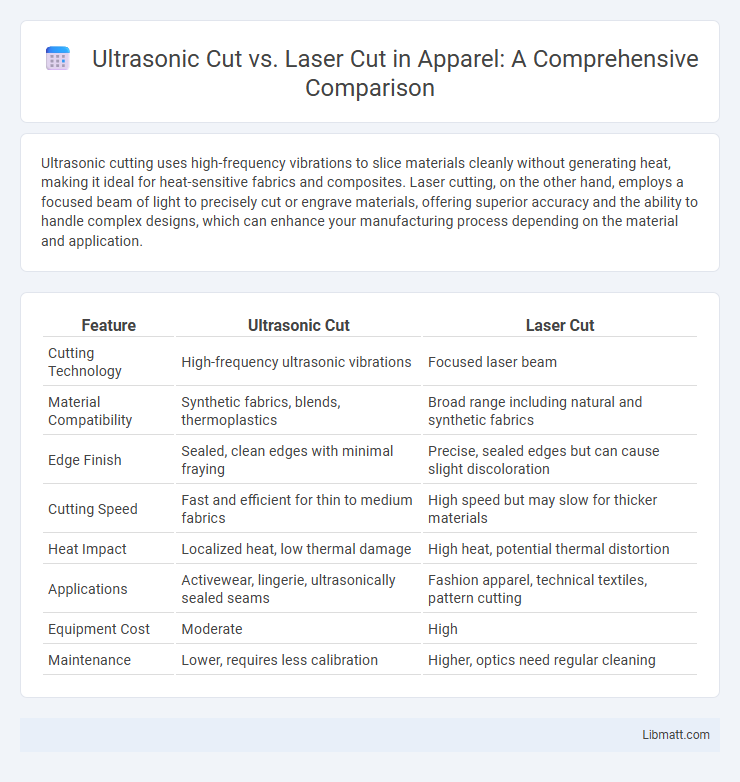

Table of Comparison

| Feature | Ultrasonic Cut | Laser Cut |

|---|---|---|

| Cutting Technology | High-frequency ultrasonic vibrations | Focused laser beam |

| Material Compatibility | Synthetic fabrics, blends, thermoplastics | Broad range including natural and synthetic fabrics |

| Edge Finish | Sealed, clean edges with minimal fraying | Precise, sealed edges but can cause slight discoloration |

| Cutting Speed | Fast and efficient for thin to medium fabrics | High speed but may slow for thicker materials |

| Heat Impact | Localized heat, low thermal damage | High heat, potential thermal distortion |

| Applications | Activewear, lingerie, ultrasonically sealed seams | Fashion apparel, technical textiles, pattern cutting |

| Equipment Cost | Moderate | High |

| Maintenance | Lower, requires less calibration | Higher, optics need regular cleaning |

Introduction to Ultrasonic and Laser Cutting Techniques

Ultrasonic cutting uses high-frequency vibrations to create precise, clean cuts by vibrating a blade against the material, making it ideal for thin, flexible, or heat-sensitive products. Laser cutting employs a focused beam of light to melt or vaporize material, offering high precision and versatility across metals, plastics, and fabrics. Your choice between ultrasonic and laser cutting depends on factors like material type, desired edge quality, and production speed.

How Ultrasonic Cutting Works: Principles and Applications

Ultrasonic cutting uses high-frequency vibrations, typically between 20 kHz and 40 kHz, to create a precise and clean cut by reducing friction and heat buildup on materials. The ultrasonic blade oscillates rapidly, allowing it to slice through soft and delicate materials like fabrics, plastics, and composites with minimal distortion or damage. You benefit from ultrasonic cutting's efficiency and precision in industries such as textiles, food processing, and medical device manufacturing, where maintaining material integrity is crucial.

Laser Cutting Explained: Process and Popular Uses

Laser cutting uses a highly focused beam of light to precisely cut or engrave materials such as metal, wood, and plastic by vaporizing or melting the target area. This process offers exceptional accuracy, intricate detail, and clean edges, making it popular in industries like aerospace, automotive, and custom manufacturing. Your choice of laser cutting enables efficient production of complex shapes and fine designs that require minimal post-processing.

Material Compatibility: Ultrasonic vs Laser Cutting

Ultrasonic cutting excels in processing delicate materials such as plastics, composites, and soft fabrics by using high-frequency vibrations that minimize heat damage and material distortion. Laser cutting offers superior precision and speed for hard materials like metals, glass, and certain polymers but may cause thermal effects including melting or charring. Your choice depends on material type and sensitivity, with ultrasonic cutting preferred for heat-sensitive, flexible materials and laser cutting ideal for rigid, heat-resistant substrates.

Precision and Edge Quality: Comparing Results

Ultrasonic cutting offers superior precision with minimal thermal damage, resulting in smooth, clean edges ideal for delicate materials. Laser cutting provides high accuracy but may cause slight heat-affected zones, leading to potential edge discoloration or warping. Edge quality from ultrasonic cuts generally excels in maintaining material integrity, while laser cuts are favored for complex, intricate designs requiring fine detail.

Speed and Efficiency: Which Method Performs Better?

Ultrasonic cutting offers faster processing speeds due to its high-frequency vibrations that reduce friction and material resistance, allowing precise and clean cuts with minimal thermal damage. Laser cutting provides high efficiency for complex shapes and fine details but often requires slower speeds to prevent heat-affected zones and material warping. For high-volume, consistent cuts, ultrasonic cutting generally outperforms laser cutting in speed and efficiency, especially for soft or composite materials.

Safety and Environmental Considerations

Ultrasonic cutting produces minimal heat and emits no harmful fumes, reducing risks of burns and toxic exposure, making it safer for operators and the environment. Laser cutting generates intense heat and potentially hazardous fumes that require proper ventilation and protective measures to ensure safety. Ultrasonic cutting also consumes less energy and results in reduced environmental impact compared to laser cutting.

Cost Analysis: Ultrasonic Cut vs Laser Cut

Ultrasonic cutting typically involves lower initial equipment costs and reduced maintenance expenses compared to laser cutting, making it cost-effective for high-volume production runs. Laser cutting, while more expensive upfront due to advanced technology and power requirements, offers higher precision and versatility that can reduce material waste and post-processing costs. Your choice between ultrasonic and laser cutting should factor in both the scale of production and the specific material properties to optimize overall cost efficiency.

Typical Industries and Use Cases for Each Method

Ultrasonic cutting is widely used in industries such as food processing, textiles, and medical device manufacturing due to its precision in cutting soft, flexible materials without causing thermal damage. Laser cutting is prevalent in automotive, aerospace, and electronics sectors, offering high-speed, accurate cuts on metals, plastics, and complex shapes. Your choice depends on material type and production requirements, as ultrasonic excels with delicate substrates while laser cutting is superior for hard, detailed components.

Choosing the Right Cutting Technology for Your Needs

Ultrasonic cutting uses high-frequency vibrations to achieve precise, clean edges with minimal heat, making it ideal for delicate fabrics and materials sensitive to thermal damage. Laser cutting offers exceptional accuracy and speed, suitable for intricate designs and hard materials, but may cause heat-affected zones or discoloration on certain substrates. Your choice depends on material type, cutting precision requirements, and production volume, ensuring optimal results for your specific application.

ultrasonic cut vs laser cut Infographic

libmatt.com

libmatt.com