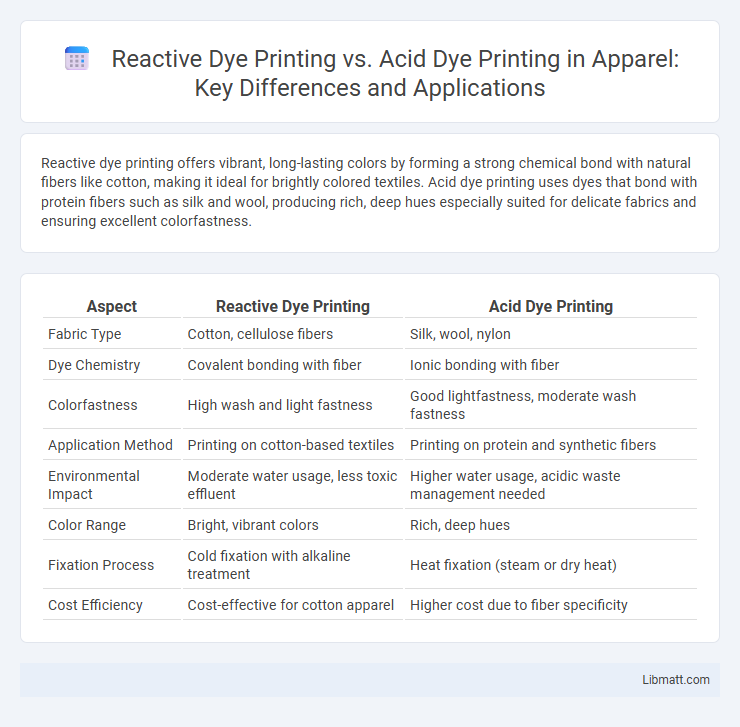

Reactive dye printing offers vibrant, long-lasting colors by forming a strong chemical bond with natural fibers like cotton, making it ideal for brightly colored textiles. Acid dye printing uses dyes that bond with protein fibers such as silk and wool, producing rich, deep hues especially suited for delicate fabrics and ensuring excellent colorfastness.

Table of Comparison

| Aspect | Reactive Dye Printing | Acid Dye Printing |

|---|---|---|

| Fabric Type | Cotton, cellulose fibers | Silk, wool, nylon |

| Dye Chemistry | Covalent bonding with fiber | Ionic bonding with fiber |

| Colorfastness | High wash and light fastness | Good lightfastness, moderate wash fastness |

| Application Method | Printing on cotton-based textiles | Printing on protein and synthetic fibers |

| Environmental Impact | Moderate water usage, less toxic effluent | Higher water usage, acidic waste management needed |

| Color Range | Bright, vibrant colors | Rich, deep hues |

| Fixation Process | Cold fixation with alkaline treatment | Heat fixation (steam or dry heat) |

| Cost Efficiency | Cost-effective for cotton apparel | Higher cost due to fiber specificity |

Introduction to Textile Dye Printing Methods

Reactive dye printing uses dyes that form a covalent bond with cellulose fibers, making them ideal for cotton and other plant-based fabrics, while acid dye printing involves ionic bonds with protein fibers like silk and wool, ensuring vibrant colors with excellent wash fastness. Your choice between reactive and acid dye printing depends on the fiber type and desired colorfastness; reactive dyes offer brilliant, long-lasting hues on cellulose, whereas acid dyes provide rich, vivid colors on protein fibers. Understanding these fundamental differences in dye chemistry helps optimize textile production for specific fabric types and end-use applications.

Overview of Reactive Dye Printing

Reactive dye printing involves bonding reactive dyes with cellulose fibers, primarily cotton, producing vibrant and long-lasting colors that resist fading. This method uses a chemical reaction between the dye and fabric, resulting in excellent wash and light fastness, making it ideal for textile applications requiring durability. Reactive dye printing is favored for its eco-friendly process, lower water consumption, and ability to achieve soft-touch fabrics compared to other dyeing techniques like acid dye printing.

Overview of Acid Dye Printing

Acid dye printing involves the application of acid dyes, which bind chemically to protein fibers such as silk, wool, and nylon, producing vibrant, long-lasting colors. This method requires an acidic environment, typically using a vinegar or citric acid fixative, to ensure proper dye fixation and colorfastness. Your choice of acid dye printing is ideal for achieving bright, detailed designs on protein-based textiles with excellent wash resistance.

Fiber Compatibility: Reactive vs Acid Dyes

Reactive dyes are specifically compatible with cellulose fibers such as cotton, linen, and rayon, forming strong covalent bonds that ensure vibrant, long-lasting prints. Acid dyes, on the other hand, are primarily used with protein fibers like wool, silk, and nylon, relying on ionic bonds that provide excellent color brightness and wash fastness. Your choice between reactive and acid dye printing should depend on the fiber type of your fabric to achieve optimal dye adherence and durability.

Color Fastness Comparison

Reactive dye printing generally offers superior color fastness on cellulose fibers like cotton, showing excellent resistance to washing and light exposure due to covalent bonding between dye and fiber. Acid dye printing is primarily used on protein fibers such as silk and wool, providing vibrant colors but lower wash fastness compared to reactive dyes, with some susceptibility to fading over time. The choice between reactive and acid dye printing depends largely on fiber type and desired durability, with reactive dyes favored for long-lasting color retention on cellulosic textiles.

Printing Process Differences

Reactive dye printing uses reactive dyes that form a covalent bond with cellulose fibers, requiring a fixation process involving heat or steam to ensure colorfastness on natural fabrics like cotton. Acid dye printing relies on acid dyes that bind to protein fibers such as silk or wool through ionic bonds, typically necessitating steaming or curing at lower temperatures compared to reactive dyes. Your choice between the two printing processes depends on the fabric type and the desired durability and vibrancy of the print.

Environmental Impact of Each Method

Reactive dye printing uses fiber-reactive dyes that form covalent bonds with cellulose fibers, resulting in vibrant colors but generating wastewater with high salinity and alkali content, requiring effective treatment to minimize environmental harm. Acid dye printing, commonly used for protein fibers like silk and wool, relies on metal complex dyes that can produce effluents containing heavy metals and acidic residues, posing risks to aquatic ecosystems if not properly managed. To reduce your environmental footprint, consider opting for printing methods with advanced wastewater treatment or eco-friendly dye alternatives that lower chemical discharge.

Cost Analysis: Reactive vs Acid Dye Printing

Reactive dye printing generally offers lower overall production costs compared to acid dye printing due to the affordability of reactive dyes and the use of less specialized equipment. Acid dye printing often incurs higher expenses linked to the need for precise pH control, specialized fixation processes, and greater energy consumption during printing and curing. Cost efficiency in reactive dye printing makes it preferable for large-scale cotton fabric production, while acid dye printing remains more expensive but ideal for protein fibers like silk and wool where vibrant, wash-fast colors are required.

Common Applications and End Uses

Reactive dye printing is widely used for cotton and other cellulose fibers, making it ideal for producing vibrant, long-lasting prints on apparel, home textiles, and fashion accessories. Acid dye printing is primarily suited for protein fibers like wool, silk, and nylon, commonly applied in high-end garments, upholstery fabrics, and luxury scarves. The choice between these printing methods depends on the fabric type and desired color fastness for specific end uses.

Choosing the Right Printing Method

Reactive dye printing offers vibrant, long-lasting colors on natural fibers like cotton by forming strong covalent bonds, making it ideal for durable textile applications. Acid dye printing excels on protein fibers such as silk and wool, providing bright hues and excellent wash fastness through ionic bonding. Selecting the right printing method depends on the fabric type, colorfastness requirements, and desired texture outcomes.

Reactive Dye Printing vs Acid Dye Printing Infographic

libmatt.com

libmatt.com