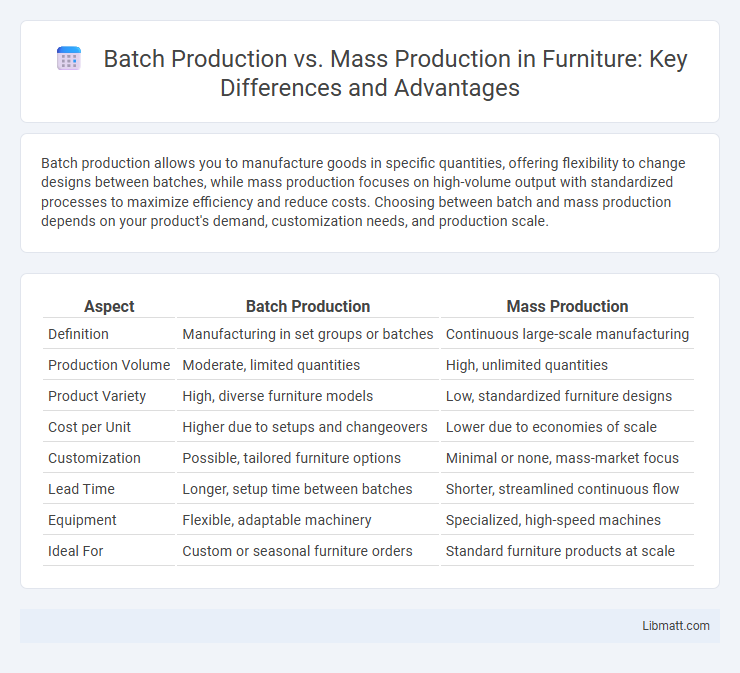

Batch production allows you to manufacture goods in specific quantities, offering flexibility to change designs between batches, while mass production focuses on high-volume output with standardized processes to maximize efficiency and reduce costs. Choosing between batch and mass production depends on your product's demand, customization needs, and production scale.

Table of Comparison

| Aspect | Batch Production | Mass Production |

|---|---|---|

| Definition | Manufacturing in set groups or batches | Continuous large-scale manufacturing |

| Production Volume | Moderate, limited quantities | High, unlimited quantities |

| Product Variety | High, diverse furniture models | Low, standardized furniture designs |

| Cost per Unit | Higher due to setups and changeovers | Lower due to economies of scale |

| Customization | Possible, tailored furniture options | Minimal or none, mass-market focus |

| Lead Time | Longer, setup time between batches | Shorter, streamlined continuous flow |

| Equipment | Flexible, adaptable machinery | Specialized, high-speed machines |

| Ideal For | Custom or seasonal furniture orders | Standard furniture products at scale |

Understanding Batch Production

Batch production involves manufacturing goods in specific groups or quantities, allowing customization and flexibility compared to mass production. This method optimizes resource use and reduces waste by producing items in manageable lots that meet fluctuating demand. Your business can benefit from batch production when variable output and frequent product changes are necessary.

Defining Mass Production

Mass production is a manufacturing process aimed at producing large quantities of standardized products efficiently, often using assembly lines and automation. This method reduces costs per unit by maximizing economies of scale and minimizing production time. Understanding how your operation compares to mass production can help determine the best approach for balancing volume, customization, and cost.

Key Differences Between Batch and Mass Production

Batch production involves manufacturing goods in specific groups or quantities, allowing for customization and flexibility in product design. Mass production focuses on continuous, high-volume output of standardized products using automated processes to achieve economies of scale. Key differences include batch production's adaptability to varying customer demands versus mass production's emphasis on efficiency and cost reduction through uniformity.

Advantages of Batch Production

Batch production offers greater flexibility in manufacturing, allowing companies to produce varied products in smaller quantities while efficiently managing resources and reducing inventory costs. This method enhances quality control by enabling adjustments between batches, minimizing defects and waste. It is ideal for businesses responding to market demand fluctuations or requiring customization without the high setup costs associated with mass production.

Benefits of Mass Production

Mass production offers significant benefits such as economies of scale, which reduce the cost per unit and boost overall profitability. It enables consistent product quality and high output rates, meeting large demand efficiently. Your business can achieve faster production cycles and streamlined processes, enhancing competitiveness in the marketplace.

Limitations of Batch Production

Batch production faces limitations such as higher setup times and costs due to frequent changes between product batches, leading to lower efficiency compared to continuous processes. It often results in increased inventory holding and storage requirements, causing potential delays if demand forecasts are inaccurate. The flexibility of batch production comes at the expense of slower throughput rates and inconsistent workflow compared to mass production.

Challenges in Mass Production

Mass production faces challenges like high initial capital investment in automated machinery and assembly lines, which can strain financial resources. Maintaining consistent quality at large volumes requires stringent quality control systems and can be disrupted by equipment malfunctions or supply chain issues. Furthermore, mass production lacks flexibility, making it difficult to quickly adapt to market changes or customize products for niche demands.

Choosing Between Batch and Mass Production

Choosing between batch production and mass production depends on product variety, production volume, and market demand. Batch production offers flexibility for customized or seasonal products with moderate volume, reducing inventory costs and adapting to changing customer preferences. Mass production excels in high-volume, standardized goods, maximizing efficiency and lowering per-unit costs through automation and continuous flow processes.

Industry Examples: Batch vs Mass Production

Batch production is commonly employed in industries like pharmaceuticals and specialty food manufacturing where customized or seasonal products are produced in specific quantities. Mass production dominates sectors such as automotive and electronics manufacturing, where large volumes of standardized products like cars and smartphones are created efficiently. Your choice between batch vs mass production depends on factors including product variety, volume demand, and flexibility requirements.

Future Trends in Manufacturing Production Methods

Future trends in manufacturing highlight a shift towards flexible batch production driven by digitalization and Industry 4.0 technologies, enabling customizable, small to medium-sized product runs with reduced lead times. Mass production continues to optimize efficiency through automation and AI-driven predictive maintenance, enhancing scalability and cost-effectiveness for high-volume output. Hybrid production models integrating batch and mass techniques are emerging, leveraging data analytics and smart factories to balance customization with economies of scale.

Batch production vs mass production Infographic

libmatt.com

libmatt.com