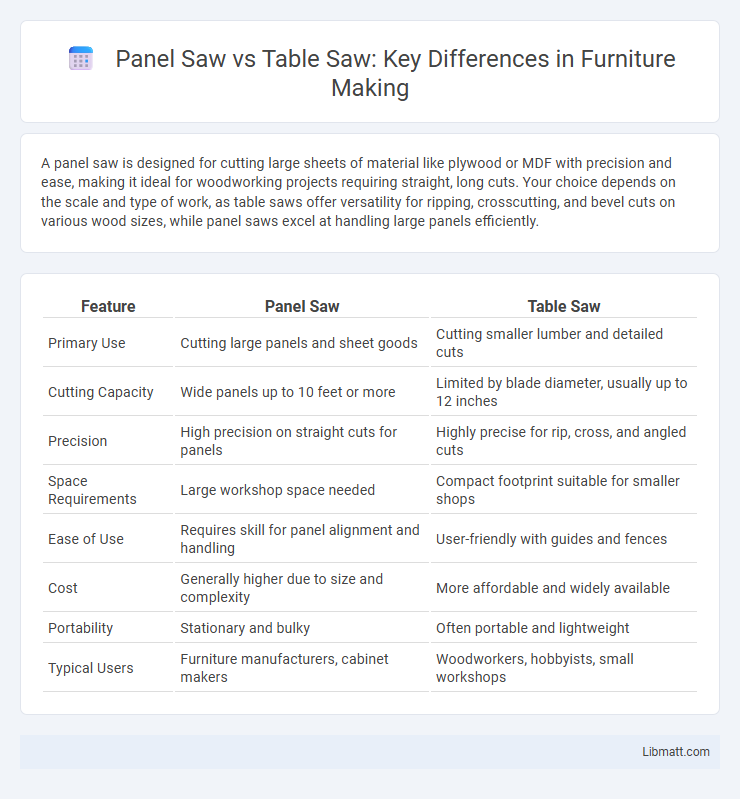

A panel saw is designed for cutting large sheets of material like plywood or MDF with precision and ease, making it ideal for woodworking projects requiring straight, long cuts. Your choice depends on the scale and type of work, as table saws offer versatility for ripping, crosscutting, and bevel cuts on various wood sizes, while panel saws excel at handling large panels efficiently.

Table of Comparison

| Feature | Panel Saw | Table Saw |

|---|---|---|

| Primary Use | Cutting large panels and sheet goods | Cutting smaller lumber and detailed cuts |

| Cutting Capacity | Wide panels up to 10 feet or more | Limited by blade diameter, usually up to 12 inches |

| Precision | High precision on straight cuts for panels | Highly precise for rip, cross, and angled cuts |

| Space Requirements | Large workshop space needed | Compact footprint suitable for smaller shops |

| Ease of Use | Requires skill for panel alignment and handling | User-friendly with guides and fences |

| Cost | Generally higher due to size and complexity | More affordable and widely available |

| Portability | Stationary and bulky | Often portable and lightweight |

| Typical Users | Furniture manufacturers, cabinet makers | Woodworkers, hobbyists, small workshops |

Introduction to Panel Saw and Table Saw

Panel saws are specialized woodworking tools designed for efficiently cutting large panels of wood, plywood, or MDF into precise sizes, often used in cabinetry and furniture production. Table saws feature a circular blade mounted on an arbor, allowing versatile and accurate rip cuts, crosscuts, and bevels on various wood materials. Your choice depends on the scale and type of cuts required, with panel saws excelling in large sheet handling and table saws providing greater flexibility for detailed woodworking tasks.

Key Differences Between Panel Saw and Table Saw

Panel saws are designed primarily for cutting large sheet materials like plywood and MDF, featuring vertical or horizontal configurations to save space and improve accuracy in ripping and crosscutting. Table saws, equipped with a circular blade mounted on an arbor beneath a flat table surface, offer versatility for various woodworking tasks including ripping, crosscutting, bevel cuts, and dado cuts, commonly used for smaller to medium-sized workpieces. The key differences lie in their application scope, with panel saws optimized for large panels and space efficiency, while table saws provide more precision and flexibility for detailed woodworking projects.

Design and Structure Comparison

Panel saws feature a vertical design that optimizes space and facilitates cutting large sheets with precision, making them ideal for woodworking shops prioritizing efficiency. Table saws have a horizontal structure with a flat, large surface and a circular blade protruding through, offering versatility for ripping, crosscutting, and bevel cuts on smaller wood pieces. Your choice depends on workspace layout and the specific type of cuts you frequently perform.

Cutting Capacity and Versatility

Panel saws provide superior cutting capacity with their ability to handle large sheet materials like plywood or MDF effortlessly, making them ideal for extensive panel processing tasks. Table saws offer greater versatility for various cuts including ripping, crosscutting, and beveling smaller stock, suitable for detailed woodworking projects. Your choice depends on whether you prioritize handling large panels or require flexible cutting options for diverse woodworking tasks.

Precision and Accuracy

Panel saws offer high precision and accuracy in cutting large sheets of material, ensuring straight and consistent cuts with minimal manual effort. Table saws provide versatile precision, especially for rip cuts and angled cuts, with adjustable fences and miter gauges enhancing accuracy for detailed woodworking. Your choice between a panel saw and table saw depends on the specific material size and type of cuts you require for optimal precision.

Safety Features and Considerations

Panel saws typically offer enhanced safety features such as enclosed blades and automatic blade guards, reducing the risk of accidental contact during operation. Table saws require the use of safety accessories like riving knives, anti-kickback pawls, and push sticks to prevent kickback and finger injuries, demanding greater user vigilance. For your workshop, prioritizing machines with integrated safety mechanisms and adhering to proper usage techniques ensures a safer cutting environment.

Space and Portability

Panel saws are designed for vertical use, saving valuable floor space in workshops and making them ideal for handling large sheet materials without requiring a large footprint. Table saws tend to be bulkier and heavier, often limiting mobility and necessitating more dedicated space for operation and storage. Your choice depends on whether portability or compact vertical storage is a higher priority for your workspace needs.

Ideal Use Cases for Each Saw

Panel saws excel in cutting large sheets of plywood, MDF, and other sheet goods with precision and minimal effort, making them ideal for cabinetry and furniture manufacturing. Table saws offer greater versatility for ripping, crosscutting, and creating intricate joinery on smaller pieces of wood, perfect for detailed woodworking and general carpentry tasks. Choosing the right saw depends on your project scale and material type, ensuring efficient and accurate cuts every time.

Cost and Maintenance

Panel saws typically cost less upfront and have lower maintenance expenses due to their simpler mechanics and fewer moving parts. Table saws often require regular blade replacements, motor upkeep, and occasional calibration, increasing long-term maintenance costs. Your choice should consider not only the initial investment but also the ongoing expenses associated with each saw type.

Which Saw Should You Choose?

Choosing between a panel saw and a table saw depends on the nature of your woodworking projects and workspace. Panel saws excel in cutting large sheet materials like plywood quickly and with precision, ideal for production environments or workshops handling big panels. Table saws offer versatility for ripping, crosscutting, and bevel cuts on smaller boards, making them a better choice for general-purpose woodworking and detail work in your home workshop.

Panel saw vs table saw Infographic

libmatt.com

libmatt.com