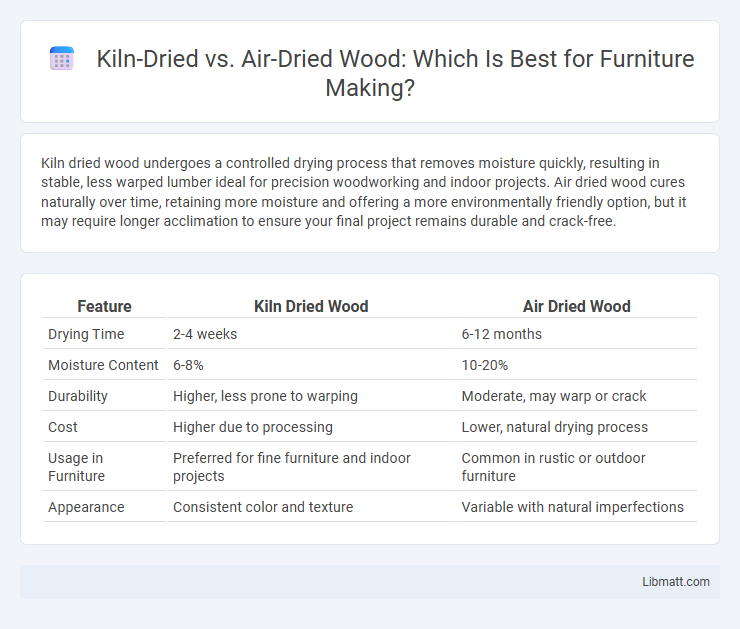

Kiln dried wood undergoes a controlled drying process that removes moisture quickly, resulting in stable, less warped lumber ideal for precision woodworking and indoor projects. Air dried wood cures naturally over time, retaining more moisture and offering a more environmentally friendly option, but it may require longer acclimation to ensure your final project remains durable and crack-free.

Table of Comparison

| Feature | Kiln Dried Wood | Air Dried Wood |

|---|---|---|

| Drying Time | 2-4 weeks | 6-12 months |

| Moisture Content | 6-8% | 10-20% |

| Durability | Higher, less prone to warping | Moderate, may warp or crack |

| Cost | Higher due to processing | Lower, natural drying process |

| Usage in Furniture | Preferred for fine furniture and indoor projects | Common in rustic or outdoor furniture |

| Appearance | Consistent color and texture | Variable with natural imperfections |

Understanding Wood Drying Methods

Kiln dried wood undergoes controlled heat and humidity treatment in a kiln, reducing moisture content to around 6-8%, which enhances stability, strength, and resistance to fungal decay. Air dried wood is naturally dried outdoors or in well-ventilated spaces, with moisture content typically around 12-20%, resulting in slower drying times but preserving more natural wood characteristics. Understanding these drying methods is crucial for selecting wood with optimal durability, workability, and suitability for specific construction or woodworking projects.

What is Kiln Dried Wood?

Kiln dried wood undergoes a controlled drying process inside a specialized kiln, where temperature, humidity, and airflow are precisely regulated to remove moisture content efficiently. This method reduces the wood's moisture levels to around 6-8%, resulting in enhanced durability, stability, and resistance to warping or shrinking compared to air dried wood. Kiln drying also eliminates pests and fungi, making it ideal for construction, furniture making, and indoor applications where consistent wood quality is critical.

What is Air Dried Wood?

Air dried wood is lumber that has been naturally dried by exposing it to ambient air, allowing moisture to evaporate over weeks or months, resulting in a moisture content typically between 12% and 20%. This drying process reduces the risk of warping and splitting while preserving the wood's natural strength and appearance, making it suitable for furniture, cabinetry, and construction. Unlike kiln dried wood, air dried timber maintains more organic characteristics, often favored for its cost-effectiveness and eco-friendly drying method.

Moisture Content Comparison

Kiln dried wood typically has a moisture content of 6-8%, offering greater stability and resistance to warping compared to air dried wood, which usually contains 12-20% moisture. This lower moisture level in kiln dried wood enhances durability and is ideal for interior applications where precise dimensions are critical. Understanding the moisture content differences helps you choose the best wood type for your specific project needs.

Drying Time: Kiln vs Air

Kiln drying reduces wood moisture content to optimal levels within days by using controlled heat and humidity, significantly faster than air drying, which can take several months to over a year depending on species and climate. The accelerated drying process in kilns minimizes the risk of fungal growth and insect infestation, ensuring consistent quality and stability. Air drying relies on natural airflow and ambient conditions, resulting in unpredictable drying times and potential surface checking or warping.

Quality and Stability Differences

Kiln dried wood offers superior quality and stability due to controlled drying in a high-temperature environment, reducing moisture content to a precise level that minimizes warping and cracking. Air dried wood retains higher moisture levels and can experience uneven drying, leading to potential dimensional changes and lower overall durability. Your choice between kiln dried and air dried wood directly impacts the longevity and performance of woodworking projects, with kiln dried wood preferred for critical applications requiring dimensional accuracy and strength.

Cost Implications of Each Method

Kiln dried wood typically incurs higher costs due to the energy-intensive drying process and specialized equipment required, which results in reduced moisture content and greater dimensional stability. Air dried wood is generally more cost-effective, relying on natural drying over an extended period, but may retain higher moisture levels and potential for warping or insect infestation. Considering long-term value, kiln dried wood often reduces waste and maintenance expenses, justifying the initial investment in projects demanding precision and durability.

Environmental Impact Considerations

Kiln dried wood undergoes a controlled drying process using heat, which consumes energy and may contribute to carbon emissions depending on the energy source. Air dried wood relies on natural airflow, reducing energy consumption and lowering its environmental footprint, though it requires longer drying times. Choosing between kiln dried and air dried wood depends on balancing your need for resource efficiency with environmental impact priorities.

Best Uses for Kiln Dried Wood

Kiln dried wood is ideal for indoor furniture, cabinetry, and flooring due to its low moisture content, typically reduced to 6-8%, which prevents warping, shrinking, and insect infestation. This controlled drying process ensures higher dimensional stability, making it suitable for precise wood joinery and fine woodworking projects. Kiln dried lumber is also preferred in construction applications requiring quick installation and painting, as it absorbs finishes evenly and dries faster than air dried wood.

Best Uses for Air Dried Wood

Air dried wood is ideal for furniture making, outdoor projects, and rustic cabinetry due to its natural moisture content and stable drying process. This wood retains more moisture than kiln dried wood, which helps reduce cracking and warping in controlled environments. Your choice of air dried wood supports environmentally friendly practices while providing durability for craft and construction applications.

Kiln Dried vs Air Dried Wood Infographic

libmatt.com

libmatt.com