Mortise and tenon joints provide superior strength and durability ideal for heavy-duty woodworking projects, while dowel joints offer quicker assembly and alignment with less specialized tools required. Understanding your project's requirements helps you choose the best joint to ensure Your furniture or structure remains sturdy and long-lasting.

Table of Comparison

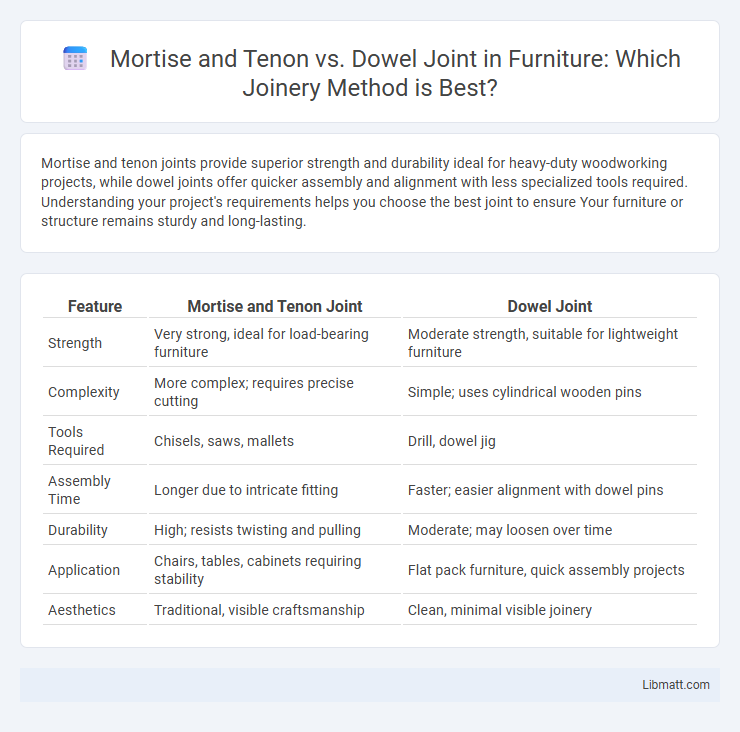

| Feature | Mortise and Tenon Joint | Dowel Joint |

|---|---|---|

| Strength | Very strong, ideal for load-bearing furniture | Moderate strength, suitable for lightweight furniture |

| Complexity | More complex; requires precise cutting | Simple; uses cylindrical wooden pins |

| Tools Required | Chisels, saws, mallets | Drill, dowel jig |

| Assembly Time | Longer due to intricate fitting | Faster; easier alignment with dowel pins |

| Durability | High; resists twisting and pulling | Moderate; may loosen over time |

| Application | Chairs, tables, cabinets requiring stability | Flat pack furniture, quick assembly projects |

| Aesthetics | Traditional, visible craftsmanship | Clean, minimal visible joinery |

Introduction to Mortise and Tenon and Dowel Joints

Mortise and tenon joints create strong, interlocking connections by inserting a tenon into a precisely cut mortise, widely used in traditional woodworking for furniture and frame construction. Dowel joints rely on cylindrical wooden pins inserted into aligned holes in adjoining pieces, offering a simpler and quicker alternative for reinforcing butt joints. Both methods provide structural integrity but differ in complexity, strength, and application depending on project requirements.

Historical Background of Joinery Techniques

Mortise and tenon joints have been used for thousands of years, dating back to ancient Egyptian and Chinese woodworking, known for their strength and durability in timber framing. Dowel joints emerged later as a simpler, more modern alternative, gaining popularity during the Industrial Revolution with the advent of precision machinery for mass production. Your choice between these techniques depends on the balance between traditional craftsmanship and modern efficiency in woodworking projects.

Structural Strength Comparison

Mortise and tenon joints provide superior structural strength compared to dowel joints due to their larger gluing surface and mechanical interlocking, which enhances load-bearing capacity and resistance to shear forces. Dowel joints, while easier to assemble and align, rely primarily on the adhesive strength of dowels inserted into drilled holes, making them less durable under heavy stress or long-term use. For projects requiring maximum stability and longevity, your choice should favor mortise and tenon construction for enhanced joint integrity.

Ease of Construction and Assembly

Mortise and tenon joints offer superior strength and precise alignment but require advanced woodworking skills and specialized tools, making their construction and assembly more challenging. Dowel joints are easier and quicker to create using common tools and pre-made dowels, allowing for faster assembly but potentially sacrificing long-term durability. Your choice depends on balancing the need for structural integrity against the simplicity and speed of construction.

Tools and Materials Required

Mortise and tenon joints require tools such as chisels, mortising machines, and marking gauges, alongside hardwood for durability and precision. Dowel joints utilize dowel pins, drill bits, clamps, and woodworking glue, suitable for softer woods or thinner materials. Both joints demand accurate measurement tools like rulers or squares for alignment and strength optimization.

Applications in Furniture and Woodworking

Mortise and tenon joints offer superior strength and durability, making them ideal for structural furniture components like chair frames and table legs that require long-lasting support. Dowel joints provide quicker assembly and are commonly used in cabinetry and smaller woodworking projects where alignment and ease of construction are priorities. Your choice depends on the balance between mechanical strength and production efficiency needed for the specific furniture application.

Durability and Longevity

Mortise and tenon joints offer superior durability and longevity due to their large glue surface area and interlocking design that resists shear and tensile stresses effectively. Dowel joints, while easier to assemble, typically provide less strength and can degrade faster under heavy loads or environmental changes because dowels rely primarily on glue without the mechanical interlock of mortise and tenon. For high-stress applications or furniture intended for long-term use, mortise and tenon joints are widely preferred for their proven stability and resistance to joint failure over time.

Aesthetic Considerations

Mortise and tenon joints provide a clean, traditional appearance with minimal visible hardware, enhancing the craftsmanship and elegance of wooden furniture. Dowel joints typically show small circular marks where the dowels are inserted, which can be concealed but may affect the seamless look slightly. Choosing between these joints often depends on the desired visual appeal and whether the joinery itself is intended to be a focal design feature.

Cost and Time Efficiency

Mortise and tenon joints typically require more skill and time to craft, which can increase labor costs compared to dowel joints. Dowel joints use pre-cut wooden rods that simplify assembly and reduce construction time, resulting in cost savings. For large-scale or production work, dowel joints provide superior time efficiency, while mortise and tenon joints offer greater strength but with higher initial labor investment.

Choosing the Right Joint for Your Project

Mortise and tenon joints offer superior strength and durability, making them ideal for load-bearing furniture and traditional woodworking projects. Dowel joints provide easier alignment and faster assembly, suitable for lightweight frames or cabinetry where precision and speed are prioritized. Selecting the right joint depends on factors like structural requirements, tooling available, and desired finish quality.

Mortise and Tenon vs Dowel Joint Infographic

libmatt.com

libmatt.com