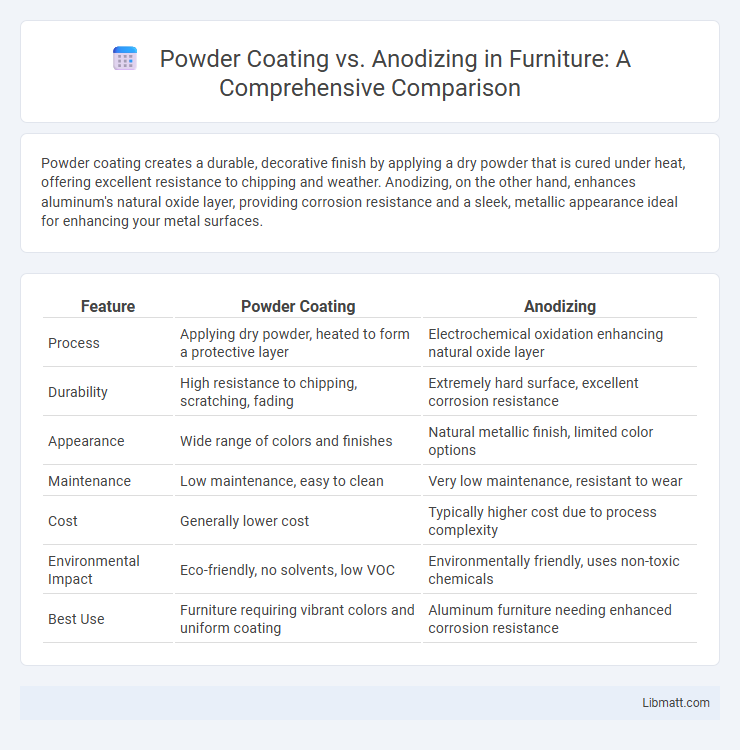

Powder coating creates a durable, decorative finish by applying a dry powder that is cured under heat, offering excellent resistance to chipping and weather. Anodizing, on the other hand, enhances aluminum's natural oxide layer, providing corrosion resistance and a sleek, metallic appearance ideal for enhancing your metal surfaces.

Table of Comparison

| Feature | Powder Coating | Anodizing |

|---|---|---|

| Process | Applying dry powder, heated to form a protective layer | Electrochemical oxidation enhancing natural oxide layer |

| Durability | High resistance to chipping, scratching, fading | Extremely hard surface, excellent corrosion resistance |

| Appearance | Wide range of colors and finishes | Natural metallic finish, limited color options |

| Maintenance | Low maintenance, easy to clean | Very low maintenance, resistant to wear |

| Cost | Generally lower cost | Typically higher cost due to process complexity |

| Environmental Impact | Eco-friendly, no solvents, low VOC | Environmentally friendly, uses non-toxic chemicals |

| Best Use | Furniture requiring vibrant colors and uniform coating | Aluminum furniture needing enhanced corrosion resistance |

Introduction to Surface Finishing Techniques

Powder coating and anodizing are two essential surface finishing techniques that enhance durability and appearance of metal parts. Powder coating involves applying a dry powder that is cured under heat to form a tough, protective layer resistant to corrosion and wear. Anodizing, on the other hand, is an electrochemical process that thickens the natural oxide layer on aluminum, improving corrosion resistance and providing a decorative finish.

What is Powder Coating?

Powder coating is a dry finishing process that applies a protective and decorative layer to metal surfaces using powdered pigments and resins. This coating is electrostatically sprayed onto the substrate, then cured under heat to form a durable, smooth, and resistant finish. You benefit from powder coating's excellent corrosion resistance, impact toughness, and vibrant color options ideal for industrial and automotive applications.

What is Anodizing?

Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum surfaces, improving corrosion resistance, durability, and aesthetic appeal. This treatment creates a hard, protective coating that is integral to the metal, preventing wear and fading over time. Unlike powder coating, anodizing does not add a layer on top but strengthens the aluminum itself, making it ideal for applications where longevity and a sleek finish are essential for your projects.

Key Differences Between Powder Coating and Anodizing

Powder coating creates a thick, durable finish by applying a dry powder that is cured under heat, providing excellent resistance to chipping, scratching, and corrosion. Anodizing is an electrochemical process that enhances the natural oxide layer on metal surfaces, mainly aluminum, improving corrosion resistance and surface hardness while maintaining a metallic appearance. Your choice between powder coating and anodizing depends on the desired finish durability, aesthetic, and environmental resistance requirements for your project.

Durability and Corrosion Resistance Comparison

Powder coating offers superior impact resistance and a thicker protective layer, making it highly durable for outdoor applications subject to abrasion and weathering. Anodizing creates a hard, corrosion-resistant oxide layer that is chemically bonded to the aluminum surface, enhancing long-term resistance to oxidation and UV damage. While powder coating excels in resisting chipping and cracking, anodizing provides better protection against corrosion in marine and industrial environments.

Color and Finish Options

Powder coating offers a wider range of vibrant color options and customizable finishes, including matte, glossy, and textured surfaces, making it ideal for aesthetic versatility. Anodizing provides a durable, natural metallic finish with limited color choices primarily in shades of silver, black, blue, and bronze, enhancing corrosion resistance while maintaining the metal's integrity. Your decision between powder coating and anodizing will depend on whether you prioritize extensive color variety or a protective, long-lasting metallic finish.

Environmental Impact and Safety

Powder coating produces fewer volatile organic compounds (VOCs) and hazardous air pollutants compared to traditional liquid paints, making it a safer choice for both workers and the environment due to its non-toxic, waste-minimizing application process. Anodizing is an electrochemical process that consumes significant energy and uses acidic solutions, which require careful handling and disposal to prevent environmental contamination, but it results in a durable, corrosion-resistant finish without hazardous emissions. You should consider powder coating for lower environmental impact and safer workplace conditions, while anodizing demands strict safety protocols to manage chemical use and waste.

Cost Analysis: Powder Coating vs Anodizing

Powder coating generally offers a lower upfront cost compared to anodizing, making it a cost-effective choice for large-scale projects requiring vibrant, durable finishes. Anodizing involves higher initial expenses due to complex chemical processes and equipment but provides superior corrosion resistance and finish longevity, potentially reducing maintenance costs over time. Your decision between powder coating and anodizing should factor in the total lifecycle cost, including durability, aesthetic requirements, and environmental impact, to optimize value.

Typical Applications and Industries

Powder coating excels in automotive, architectural, and appliance industries due to its durable, colorful finish suited for metal and some plastic surfaces. Anodizing is primarily used in aerospace, electronics, and consumer goods, enhancing aluminum parts with corrosion resistance and a natural oxide layer. Your choice depends on application needs, with powder coating favored for thick, decorative coatings and anodizing chosen for lightweight, corrosion-resistant aluminum components.

Choosing the Right Process for Your Project

Selecting between powder coating and anodizing depends on factors like desired durability, appearance, and material type. Powder coating offers a thicker, more colorful finish ideal for outdoor protection on steel, while anodizing provides a thinner, corrosion-resistant layer best suited for aluminum with a natural metallic look. Project requirements such as environmental exposure, aesthetic preferences, and maintenance needs should guide the choice of the coating process.

Powder Coating vs Anodizing Infographic

libmatt.com

libmatt.com