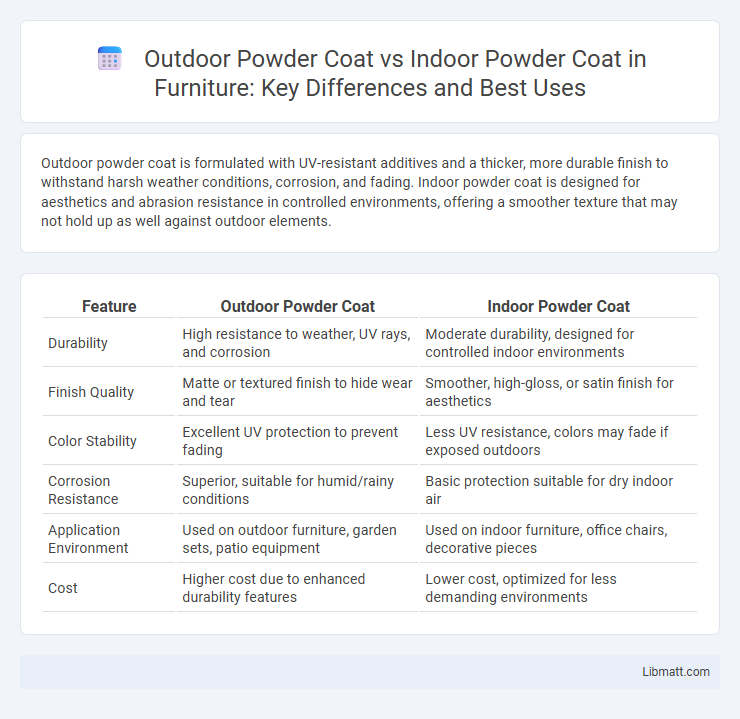

Outdoor powder coat is formulated with UV-resistant additives and a thicker, more durable finish to withstand harsh weather conditions, corrosion, and fading. Indoor powder coat is designed for aesthetics and abrasion resistance in controlled environments, offering a smoother texture that may not hold up as well against outdoor elements.

Table of Comparison

| Feature | Outdoor Powder Coat | Indoor Powder Coat |

|---|---|---|

| Durability | High resistance to weather, UV rays, and corrosion | Moderate durability, designed for controlled indoor environments |

| Finish Quality | Matte or textured finish to hide wear and tear | Smoother, high-gloss, or satin finish for aesthetics |

| Color Stability | Excellent UV protection to prevent fading | Less UV resistance, colors may fade if exposed outdoors |

| Corrosion Resistance | Superior, suitable for humid/rainy conditions | Basic protection suitable for dry indoor air |

| Application Environment | Used on outdoor furniture, garden sets, patio equipment | Used on indoor furniture, office chairs, decorative pieces |

| Cost | Higher cost due to enhanced durability features | Lower cost, optimized for less demanding environments |

Introduction to Powder Coating

Powder coating is a durable finishing process that applies a dry powder to metal surfaces before curing it under heat, creating a hard, protective layer. Outdoor powder coating formulations use UV-resistant and weatherproof powders designed to withstand harsh environmental conditions like moisture, sunlight, and temperature fluctuations. Indoor powder coatings prioritize smooth finishes and chemical resistance, as they are exposed to controlled environments with minimal exposure to UV rays and weather elements.

Key Differences Between Outdoor and Indoor Powder Coats

Outdoor powder coats are formulated with UV-resistant polymers and corrosion inhibitors to withstand weather elements, ensuring durability against sun, rain, and temperature fluctuations. Indoor powder coats prioritize aesthetic finishes and smooth textures, with less emphasis on weather resistance, making them ideal for furniture or appliances used inside controlled environments. Understanding these key differences helps you choose the right powder coat type to enhance longevity and performance based on the exposure conditions.

Durability Comparison: Outdoor vs Indoor Powder Coating

Outdoor powder coating offers superior durability due to its enhanced resistance to UV rays, moisture, and temperature fluctuations, making it ideal for harsh weather conditions. Indoor powder coating, while effective for protecting surfaces from scratches and corrosion, generally lacks the same level of UV stability and weather resistance as outdoor formulations. Selecting the appropriate powder coating depends on the environmental exposure and longevity requirements of the coated product.

Weather Resistance and Environmental Factors

Outdoor powder coating is formulated with UV-resistant resins and corrosion inhibitors to withstand intense sunlight, rain, humidity, and temperature fluctuations, ensuring long-lasting durability on metal surfaces exposed to harsh weather conditions. Indoor powder coating typically uses less robust resins as it does not require the same level of protection against environmental stressors like moisture or UV exposure. Selecting the appropriate powder coat type based on environmental factors significantly impacts the lifespan and maintenance needs of coated products in both residential and commercial applications.

UV Protection in Outdoor Powder Coats

Outdoor powder coats feature advanced UV protection additives that significantly enhance durability and color retention when exposed to sunlight. This UV resistance prevents fading, chalking, and degradation common in interior powder coats not formulated for such conditions. Consequently, outdoor powder coatings maintain structural integrity and aesthetic appeal longer under harsh environmental exposure.

Color Retention and Fading Issues

Outdoor powder coating utilizes UV-resistant pigments and advanced polymers to significantly enhance color retention and reduce fading caused by prolonged sun exposure, making it ideal for exterior applications. Indoor powder coating, while durable against wear and chemicals, typically lacks the specialized UV inhibitors and thus may experience faster color degradation when used in outdoor environments. The choice between outdoor and indoor powder coatings hinges on exposure conditions, with outdoor formulations engineered to sustain vibrant hues over years despite harsh weather.

Application Areas: Where Each Type Excels

Outdoor powder coat is ideal for environments exposed to harsh weather conditions, such as automotive parts, outdoor furniture, and architectural metal structures, providing superior UV resistance and corrosion protection. Indoor powder coat excels in applications like appliances, office equipment, and interior metal fixtures, where abrasion resistance and smooth finishes are more critical than weather durability. Selecting the appropriate powder coating depends on exposure factors, with outdoor types formulated for durability against elements and indoor types focused on aesthetic and physical wear resistance.

Cost Considerations: Outdoor vs Indoor Powder Coating

Outdoor powder coating typically incurs higher costs due to the use of specialized UV-resistant and weatherproof powders that ensure durability against sun, rain, and temperature fluctuations. Indoor powder coating offers a more cost-effective solution by utilizing standard powders suited for controlled environments, reducing material expenses and maintenance needs. Your choice between outdoor and indoor powder coating should factor in these cost differences alongside the specific environmental exposure requirements for long-lasting performance.

Maintenance Requirements for Both Types

Outdoor powder coating requires more frequent inspection and touch-ups to combat UV exposure, moisture, and temperature fluctuations, which can cause fading and corrosion. Indoor powder coating typically demands less maintenance due to reduced environmental stress, mainly requiring regular cleaning to prevent dust and dirt accumulation. Both coatings benefit from prompt removal of contaminants and periodic checks to ensure coating integrity and longevity.

Choosing the Right Powder Coat for Your Project

Outdoor powder coating is formulated with UV-resistant pigments and durable resins designed to withstand harsh weather conditions, making it ideal for exterior metal surfaces exposed to sunlight, rain, and temperature fluctuations. Indoor powder coatings prioritize smoother finishes and chemical resistance suitable for controlled environments, such as appliances and interior architectural elements. Choosing the right powder coat for your project ensures optimal durability and aesthetic appeal based on the environmental demands your items will face.

outdoor powder coat vs indoor powder coat Infographic

libmatt.com

libmatt.com