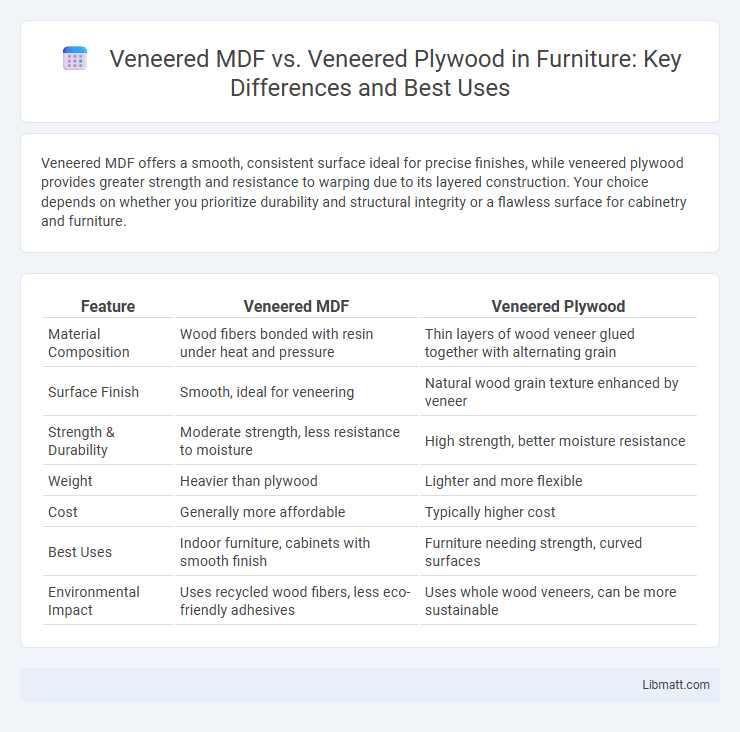

Veneered MDF offers a smooth, consistent surface ideal for precise finishes, while veneered plywood provides greater strength and resistance to warping due to its layered construction. Your choice depends on whether you prioritize durability and structural integrity or a flawless surface for cabinetry and furniture.

Table of Comparison

| Feature | Veneered MDF | Veneered Plywood |

|---|---|---|

| Material Composition | Wood fibers bonded with resin under heat and pressure | Thin layers of wood veneer glued together with alternating grain |

| Surface Finish | Smooth, ideal for veneering | Natural wood grain texture enhanced by veneer |

| Strength & Durability | Moderate strength, less resistance to moisture | High strength, better moisture resistance |

| Weight | Heavier than plywood | Lighter and more flexible |

| Cost | Generally more affordable | Typically higher cost |

| Best Uses | Indoor furniture, cabinets with smooth finish | Furniture needing strength, curved surfaces |

| Environmental Impact | Uses recycled wood fibers, less eco-friendly adhesives | Uses whole wood veneers, can be more sustainable |

Introduction to Veneered MDF and Veneered Plywood

Veneered MDF (Medium-Density Fiberboard) consists of engineered wood fibers compressed to create a smooth, stable surface ideal for applying thin wood veneers, offering a cost-effective alternative with uniform texture and excellent machinability. Veneered plywood is made by layering thin wood veneers glued perpendicularly, enhancing strength and durability while showcasing natural wood grain patterns for aesthetic appeal. Both materials serve as popular substrates in furniture and cabinetry, with veneered MDF providing consistent finish quality and veneered plywood delivering superior structural integrity.

What is Veneered MDF?

Veneered MDF is a composite wood product made from medium-density fiberboard core layers with a thin real wood veneer surface, combining affordability and aesthetic appeal. It offers smooth, uniform surfaces ideal for precise finishing and detailed edging, making it popular in furniture and cabinetry. Your choice of veneered MDF provides consistent texture and better resistance to warping compared to veneered plywood.

What is Veneered Plywood?

Veneered plywood consists of several thin layers of wood veneer glued together with alternating grain directions, providing superior strength and stability compared to veneered MDF. This construction enhances durability and resistance to warping, making it ideal for furniture and cabinetry where structural integrity is essential. Your choice between veneered plywood and MDF depends on the need for sturdiness, with plywood offering better performance in load-bearing applications.

Key Differences Between Veneered MDF and Veneered Plywood

Veneered MDF features a smooth, consistent surface ideal for painting and detailed veneering, while veneered plywood offers superior strength and resistance to warping due to its layered wood construction. MDF's engineered fibers result in higher density and uniformity, making it less susceptible to splintering but more prone to water damage compared to plywood. Veneered plywood's natural wood grain and durability make it preferred for structural applications, whereas veneered MDF is commonly used in furniture and decorative cabinetry requiring a flawless finish.

Appearance and Surface Finish Comparison

Veneered MDF offers a smooth, uniform surface with consistent texture, making it ideal for achieving a flawless, high-quality finish without natural wood imperfections. Veneered plywood retains visible grain patterns and natural knots due to its layered wood veneer construction, providing a more authentic wood appearance with varied texture. The choice between veneered MDF and plywood significantly impacts the final look, where MDF favors a sleek, polished look, and plywood emphasizes natural wood aesthetics.

Durability and Strength Factors

Veneered MDF offers smooth, uniform surfaces ideal for indoor furniture but has lower moisture resistance and structural strength compared to veneered plywood. Veneered plywood consists of multiple hardwood layers cross-laminated for enhanced durability, making it more resistant to warping and suitable for load-bearing applications. When choosing materials, consider the use environment and expected stress to ensure your project maintains long-term stability and strength.

Cost and Affordability Analysis

Veneered MDF typically offers a more budget-friendly option compared to veneered plywood due to its lower raw material and manufacturing costs, making it ideal for cost-conscious projects. Plywood's higher price reflects its superior strength and durability, which often justifies the investment in applications requiring greater load-bearing capacity and longevity. The cost difference can be significant, with veneered MDF often costing 20-30% less than veneered plywood, influencing material choice based on budget constraints and intended use.

Ease of Working and Machinability

Veneered MDF offers superior ease of working due to its uniform density and smooth surface, making it ideal for detailed machining and precise cuts without chipping. Veneered plywood presents a more complex structure with alternating grain layers, which can cause tear-out and requires sharper tools and slower feed rates for clean cuts. Your choice depends on machining needs, as MDF excels in creating intricate designs, whereas plywood is better suited for applications demanding higher strength and impact resistance.

Best Applications for Veneered MDF vs Plywood

Veneered MDF offers smooth, consistent surfaces ideal for intricate interior cabinetry, furniture, and decorative panels where fine detailing and uniform finish are essential. Veneered plywood provides superior strength and moisture resistance, making it suitable for structural elements, flooring, and outdoor furniture exposed to varying environmental conditions. Your choice depends on balancing aesthetic requirements and durability needs in specific projects.

Environmental Impact and Sustainability

Veneered MDF often has a higher environmental impact due to its reliance on formaldehyde-based resins and lower recyclability compared to veneered plywood, which uses thin layers of solid wood and typically employs less harmful adhesives. Veneered plywood is generally considered more sustainable because it utilizes renewable wood resources and offers better durability, extending product lifespan and reducing waste. Sustainable forestry certifications like FSC or PEFC enhance the eco-friendly profile of veneered plywood by ensuring responsible sourcing practices.

Veneered MDF vs veneered plywood Infographic

libmatt.com

libmatt.com