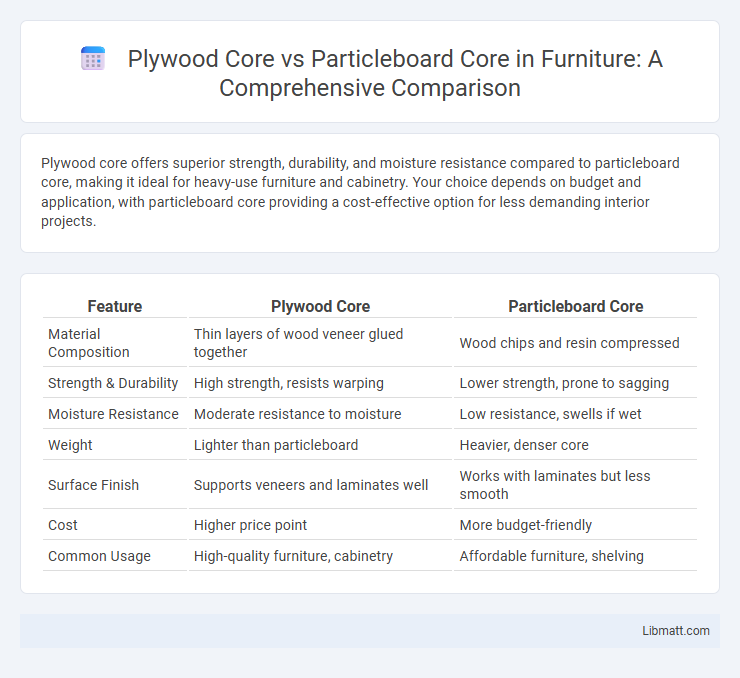

Plywood core offers superior strength, durability, and moisture resistance compared to particleboard core, making it ideal for heavy-use furniture and cabinetry. Your choice depends on budget and application, with particleboard core providing a cost-effective option for less demanding interior projects.

Table of Comparison

| Feature | Plywood Core | Particleboard Core |

|---|---|---|

| Material Composition | Thin layers of wood veneer glued together | Wood chips and resin compressed |

| Strength & Durability | High strength, resists warping | Lower strength, prone to sagging |

| Moisture Resistance | Moderate resistance to moisture | Low resistance, swells if wet |

| Weight | Lighter than particleboard | Heavier, denser core |

| Surface Finish | Supports veneers and laminates well | Works with laminates but less smooth |

| Cost | Higher price point | More budget-friendly |

| Common Usage | High-quality furniture, cabinetry | Affordable furniture, shelving |

Introduction to Plywood Core and Particleboard Core

Plywood core consists of multiple layers of thin wood veneers glued together with grains running perpendicular to each other, providing superior strength and stability. Particleboard core is made from wood chips, sawdust, and resin compressed into solid panels, offering a more affordable but less durable option. Your choice between plywood core and particleboard core depends on the balance you need between cost, weight, and structural integrity.

Composition and Manufacturing Process

Plywood core consists of multiple thin layers of wood veneers glued together with adjacent layers having their grain rotated up to 90 degrees, enhancing strength and stability through cross-lamination. Particleboard core is made from wood chips, sawmill shavings, and sawdust bonded together with synthetic resin under heat and pressure, resulting in a denser and smoother surface. The manufacturing process of plywood involves peeling logs into veneers and assembling them in layers, while particleboard is produced by compressing wood particles into panels, making plywood core preferable for durability and dimensional stability.

Strength and Durability Comparison

Plywood core offers superior strength and durability due to its cross-laminated veneer layers, providing better resistance to warping and impact compared to particleboard core, which is composed of compressed wood particles and resin. Your furniture or cabinetry will benefit from plywood's enhanced load-bearing capacity and longer lifespan, making it ideal for heavy-use applications. Particleboard core, while more affordable, tends to degrade faster under moisture exposure and heavy stress, limiting its structural reliability.

Weight and Density Differences

Plywood core typically offers higher strength and density compared to particleboard core, resulting in a sturdier and more durable panel. Particleboard core is lighter but less dense, making it more susceptible to damage and less suitable for high-load applications. Your choice between the two should consider the balance between weight and durability for the intended use.

Cost Analysis: Plywood vs Particleboard

Plywood cores typically cost more than particleboard cores due to the use of layered wood veneers, which provide superior strength and durability, making it ideal for heavy-duty applications. Particleboard cores are more budget-friendly, produced from wood chips and resin, but they lack the moisture resistance and structural integrity of plywood. Choosing between the two depends on balancing upfront material costs with long-term performance and application-specific needs.

Moisture Resistance and Environmental Impact

Plywood core offers superior moisture resistance due to its cross-laminated layers that reduce water absorption and warping, making it ideal for high-humidity environments. Particleboard core tends to absorb moisture easily, leading to swelling and structural weakening over time. Your choice of core impacts environmental sustainability, with plywood often sourced from responsibly managed forests and particleboard frequently made from recycled wood fibers but bonded with formaldehyde-based adhesives that raise eco-toxicity concerns.

Surface Finishing and Aesthetics

Plywood core panels offer a smooth and consistent surface that enhances the quality of surface finishing and allows for superior paint or veneer applications, maintaining aesthetic appeal over time. Particleboard core tends to have a more porous texture, requiring additional sealing or priming to achieve a comparable finish and often resulting in a less refined appearance. Choosing plywood core ensures your project benefits from a durable, visually appealing surface ideal for high-end furniture and cabinetry.

Common Applications in Furniture and Construction

Plywood core is widely used in furniture and construction for its superior strength, durability, and resistance to warping, making it ideal for cabinets, shelves, and structural panels. Particleboard core, while less robust, is commonly found in affordable furniture, flat-pack products, and interior wall panels due to its cost-effectiveness and ease of machining. Your choice between plywood and particleboard cores depends on the specific application requirements, balancing performance with budget constraints.

Pros and Cons of Plywood Core

Plywood core features layers of wood veneers glued together, offering superior strength, durability, and resistance to warping compared to particleboard core, which is made from compressed wood particles. The pros of plywood core include enhanced load-bearing capacity and moisture resistance, making it ideal for furniture and cabinetry; however, it tends to be more expensive and heavier than particleboard core. Cons include potential vulnerability to delamination if exposed to prolonged moisture and higher manufacturing costs, which may limit budget-conscious applications.

Pros and Cons of Particleboard Core

Particleboard core offers affordability and uniformity, making it a cost-effective option for budget-conscious projects. However, its susceptibility to moisture damage and lower screw-holding strength compared to plywood core can affect durability and longevity. Your choice depends on balancing cost with the need for strength and moisture resistance in your application.

Plywood core vs particleboard core Infographic

libmatt.com

libmatt.com