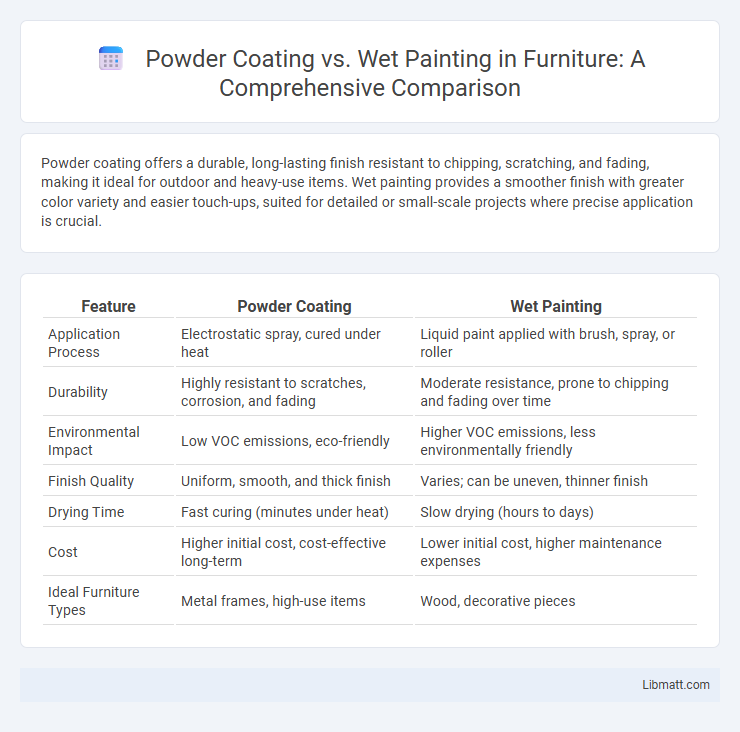

Powder coating offers a durable, long-lasting finish resistant to chipping, scratching, and fading, making it ideal for outdoor and heavy-use items. Wet painting provides a smoother finish with greater color variety and easier touch-ups, suited for detailed or small-scale projects where precise application is crucial.

Table of Comparison

| Feature | Powder Coating | Wet Painting |

|---|---|---|

| Application Process | Electrostatic spray, cured under heat | Liquid paint applied with brush, spray, or roller |

| Durability | Highly resistant to scratches, corrosion, and fading | Moderate resistance, prone to chipping and fading over time |

| Environmental Impact | Low VOC emissions, eco-friendly | Higher VOC emissions, less environmentally friendly |

| Finish Quality | Uniform, smooth, and thick finish | Varies; can be uneven, thinner finish |

| Drying Time | Fast curing (minutes under heat) | Slow drying (hours to days) |

| Cost | Higher initial cost, cost-effective long-term | Lower initial cost, higher maintenance expenses |

| Ideal Furniture Types | Metal frames, high-use items | Wood, decorative pieces |

Introduction to Powder Coating and Wet Painting

Powder coating uses dry powder applied electrostatically and cured under heat to form a tough, durable finish, ideal for metal surfaces requiring high resistance to corrosion and wear. Wet painting involves liquid paint applied with brushes, rollers, or spray guns, offering versatility in color and finish but generally less durability compared to powder coating. Your choice depends on the specific application needs, including environmental conditions, desired finish quality, and maintenance requirements.

How Powder Coating Works

Powder coating involves applying a dry, electrostatically charged powder onto a metal surface, which is then heated in a curing oven to form a hard, durable finish. This process creates a thicker, more uniform coating compared to wet painting, offering superior resistance to chipping, scratching, and fading. Understanding how powder coating works helps you choose a protective finish that enhances longevity and minimizes environmental impact.

How Wet Painting Works

Wet painting involves applying liquid paint directly onto a surface using brushes, rollers, or spray guns, where the paint consists of pigments suspended in solvents or water. As the paint dries, the solvents evaporate, leaving a solid, smooth, and durable coating that adheres to the material. This method allows for easy touch-ups and offers a wide range of colors and finishes but generally requires longer drying times and is susceptible to environmental factors during application.

Comparing Application Processes

Powder coating involves electrostatically applying dry powder to a surface and curing it under heat to create a durable, uniform finish, while wet painting requires brushing, rolling, or spraying liquid paint followed by air drying or baking. Powder coating typically provides a thicker, more consistent coating with less overspray and waste compared to wet painting, which is prone to drips and uneven layers. Understanding these differences helps you choose the appropriate method for the specific application environment and desired finish quality.

Durability and Longevity

Powder coating offers superior durability and longevity compared to wet painting due to its thicker application and resistance to chipping, scratching, and fading. The thermoset polymers used in powder coatings form a hard finish that withstands harsh environmental conditions better than conventional liquid paints. Your choice of powder coating ensures extended protection and reduced maintenance costs over time.

Surface Finish and Appearance

Powder coating delivers a thicker, more uniform surface finish that resists chipping, fading, and scratching better than wet painting, resulting in a more durable and vibrant appearance. Wet painting often offers a smoother, glossier finish initially but may suffer from drips, runs, and uneven layers, affecting long-term aesthetics. Your choice depends on whether you prioritize the long-lasting toughness of powder coating or the potentially finer initial gloss of wet paint.

Environmental Impact

Powder coating significantly reduces volatile organic compounds (VOCs) emissions compared to wet painting, making it a more environmentally friendly option. It uses electrostatically applied dry powders that minimize waste through overspray recycling, whereas wet painting produces more hazardous waste and solvent runoff. The energy efficiency and lower chemical usage in powder coating contribute to a smaller carbon footprint and better compliance with environmental regulations.

Cost Comparison

Powder coating typically offers lower long-term costs due to reduced material waste and higher durability, which minimizes the need for frequent reapplications. Wet painting often involves higher labor and solvent disposal expenses, increasing overall operational costs despite lower initial material prices. Factoring in environmental compliance and maintenance, powder coating generally proves more cost-effective for large-scale or industrial projects.

Best Use Cases for Each Method

Powder coating excels in industrial applications requiring durable, corrosion-resistant finishes, such as automotive parts, appliances, and outdoor furniture, due to its tough, long-lasting surface. Wet painting is ideal for detailed, multi-color projects or surfaces that cannot tolerate high curing temperatures, commonly used in custom artwork, residential walls, and small-scale renovations. Choosing between the two depends on factors like substrate material, environmental conditions, and desired finish quality.

Choosing the Right Coating for Your Project

Powder coating offers superior durability, corrosion resistance, and environmental benefits compared to wet painting, making it ideal for industrial applications and outdoor projects. Wet painting provides a smoother finish and greater color variety, suitable for detailed work and smaller-scale applications where precision is crucial. Your choice depends on the project's requirements for finish quality, exposure conditions, and budget constraints.

Powder coating vs wet painting Infographic

libmatt.com

libmatt.com