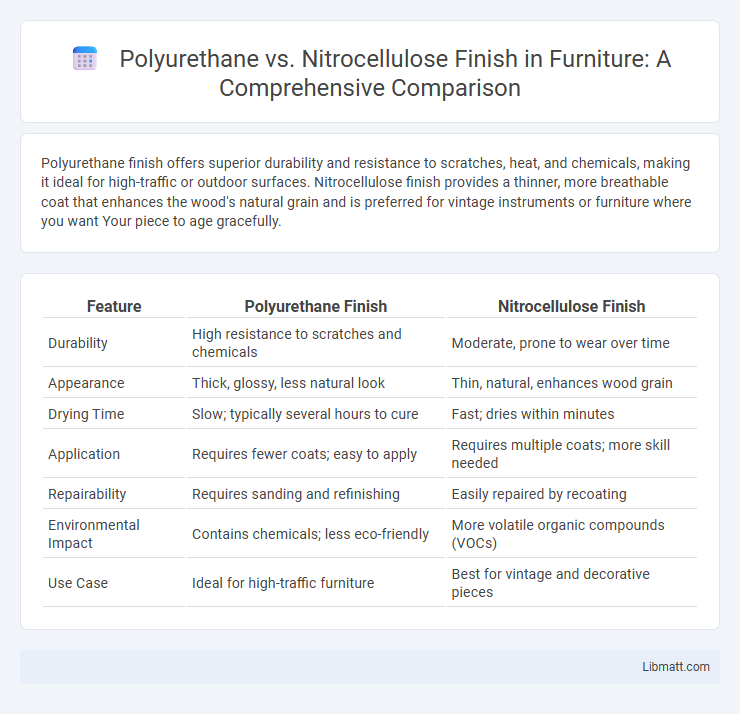

Polyurethane finish offers superior durability and resistance to scratches, heat, and chemicals, making it ideal for high-traffic or outdoor surfaces. Nitrocellulose finish provides a thinner, more breathable coat that enhances the wood's natural grain and is preferred for vintage instruments or furniture where you want Your piece to age gracefully.

Table of Comparison

| Feature | Polyurethane Finish | Nitrocellulose Finish |

|---|---|---|

| Durability | High resistance to scratches and chemicals | Moderate, prone to wear over time |

| Appearance | Thick, glossy, less natural look | Thin, natural, enhances wood grain |

| Drying Time | Slow; typically several hours to cure | Fast; dries within minutes |

| Application | Requires fewer coats; easy to apply | Requires multiple coats; more skill needed |

| Repairability | Requires sanding and refinishing | Easily repaired by recoating |

| Environmental Impact | Contains chemicals; less eco-friendly | More volatile organic compounds (VOCs) |

| Use Case | Ideal for high-traffic furniture | Best for vintage and decorative pieces |

Overview of Wood Finishes: Polyurethane vs Nitrocellulose

Polyurethane finish provides a durable, water-resistant coating ideal for high-traffic wood surfaces, offering excellent protection against scratches and chemicals. Nitrocellulose finish, known for its fast drying time and superior clarity, enhances the natural grain of wood but is less resistant to wear and moisture. When choosing between the two, polyurethane is preferred for longevity and maintenance, while nitrocellulose is favored for its vintage aesthetic and ease of repair.

Chemical Composition and Properties

Polyurethane finish, composed of synthetic polymers derived from polyols and diisocyanates, offers superior durability, chemical resistance, and moisture protection compared to nitrocellulose, which is made from cellulose treated with nitric acid and solvents. Nitrocellulose finish is known for its fast drying time and excellent clarity but is more susceptible to scratches, alcohol, and environmental wear. Your choice between these finishes should consider polyurethane's long-lasting, chemically resistant properties versus nitrocellulose's classic look and ease of repair.

Application Methods Compared

Polyurethane finishes are typically applied with brushes, rollers, or spray guns, providing a durable, moisture-resistant coating ideal for high-traffic surfaces. Nitrocellulose finishes require multiple thin coats, often applied with a spray gun or pad, to achieve their characteristic high-gloss, vintage look but are less durable and more susceptible to damage. Drying times for nitrocellulose are faster than polyurethane, which can affect workflow efficiency during application.

Curing and Drying Times

Polyurethane finish typically requires longer curing and drying times, ranging from 24 to 48 hours for full hardness, while nitrocellulose finish dries much faster, often becoming touch-dry within 30 minutes to an hour. You should consider that polyurethane's extended curing time provides a more durable and resistant coating, whereas nitrocellulose finishes offer quicker application turnaround but require multiple thin coats and additional time for full curing. Choosing between these finishes depends on your project's timeline and the level of protection needed for the surface.

Durability and Resistance to Wear

Polyurethane finish offers superior durability and resistance to wear, making it ideal for high-traffic surfaces and areas exposed to moisture or chemicals. Nitrocellulose finish, while providing a vintage aesthetic and easier repair, is more prone to scratches, dents, and wear over time. For long-lasting protection and maintaining your furniture's appearance, polyurethane is often the better choice.

Aesthetic Qualities: Gloss, Clarity, and Feel

Polyurethane finish offers a durable, high-gloss surface with excellent clarity that enhances the natural grain of your wood, providing a smooth, glass-like feel. Nitrocellulose finish, prized for its vintage appeal, delivers a softer, more satin sheen that allows the wood to breathe and ages with a distinguished patina over time. Your choice depends on whether you prefer the robust shine and clarity of polyurethane or the warm, classic texture and subtle glow of nitrocellulose.

Repairability and Maintenance

Polyurethane finishes offer superior durability and resist scratches and moisture better than nitrocellulose, making maintenance less frequent and repairs less visible. Nitrocellulose finishes, while easier to repair due to their ability to soften with solvents, require more regular care and touch-ups as they wear and chip more easily. Choosing between the two depends on balancing long-term durability against simpler, more frequent repairability.

Environmental Impact and Safety Concerns

Polyurethane finishes release volatile organic compounds (VOCs) during application, contributing to indoor air pollution and requiring proper ventilation for safety. Nitrocellulose lacquer emits higher levels of VOCs and flammable solvents, posing greater respiratory risks and fire hazards in poorly ventilated areas. You should consider eco-friendly alternatives or ensure adequate protective measures when choosing either finish to minimize environmental impact and health risks.

Cost and Availability

Polyurethane finishes generally cost more than nitrocellulose due to their durability and chemical composition, but they are widely available in most hardware and paint stores. Nitrocellulose finishes offer a lower initial cost and remain popular for vintage and custom applications, though they may be harder to find in some regions compared to polyurethane. Both finishes vary in price depending on quality and brand, with polyurethane dominating the market due to consistent availability and longer shelf life.

Choosing the Right Finish for Your Project

Polyurethane offers a durable, water-resistant finish ideal for high-traffic areas, while nitrocellulose provides a thinner, more breathable coating favored for vintage or custom guitar refinishing due to its superior aging and tonal qualities. Your project's requirements for protection, appearance, and ease of application will determine the ideal choice; polyurethane suits surfaces needing heavy-duty protection, whereas nitrocellulose enhances aesthetic appeal and natural wood resonance. Consider the finish's drying time, durability, and compatibility with your specific material to achieve the best results.

polyurethane vs nitrocellulose finish Infographic

libmatt.com

libmatt.com