Edge banding offers a flexible, cost-effective way to cover raw edges of plywood or MDF, providing a uniform finish that enhances durability and aesthetic appeal. Solid edge, made from a continuous strip of wood, delivers greater strength and a natural wood look, making it ideal for high-impact areas where longevity and seamless integration are key.

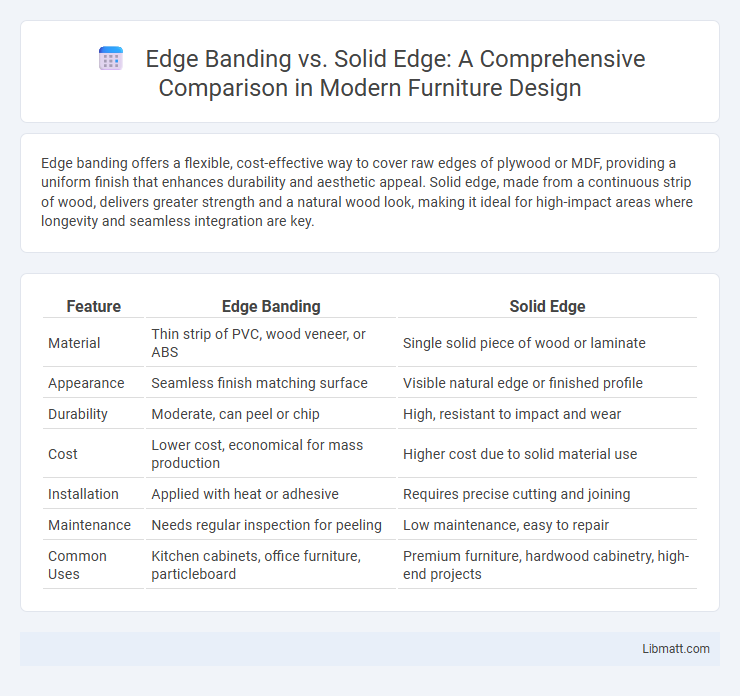

Table of Comparison

| Feature | Edge Banding | Solid Edge |

|---|---|---|

| Material | Thin strip of PVC, wood veneer, or ABS | Single solid piece of wood or laminate |

| Appearance | Seamless finish matching surface | Visible natural edge or finished profile |

| Durability | Moderate, can peel or chip | High, resistant to impact and wear |

| Cost | Lower cost, economical for mass production | Higher cost due to solid material use |

| Installation | Applied with heat or adhesive | Requires precise cutting and joining |

| Maintenance | Needs regular inspection for peeling | Low maintenance, easy to repair |

| Common Uses | Kitchen cabinets, office furniture, particleboard | Premium furniture, hardwood cabinetry, high-end projects |

Introduction to Edge Banding and Solid Edge

Edge banding is a finishing technique used to cover the exposed sides of materials like plywood, MDF, or particle board, enhancing durability and aesthetic appeal by applying a thin strip of material such as PVC, wood veneer, or melamine. Solid edge refers to furniture or cabinetry constructed with solid wood pieces forming the visible edges, offering superior strength, natural grain patterns, and the potential for refinishing. Choosing between edge banding and solid edge depends on factors like project budget, desired look, and long-term maintenance requirements.

What is Edge Banding?

Edge banding is a process that involves applying a thin strip of material, such as PVC, wood veneer, or melamine, to the exposed edges of plywood, MDF, or particle board to protect and enhance the appearance. This technique improves durability by preventing moisture damage and provides a smooth, finished look that mimics solid wood. When choosing edge banding for your furniture or cabinetry, consider the material type for optimal matching with your design and usage needs.

What is Solid Edge in Woodworking?

Solid edge in woodworking refers to a durable, thick strip of wood veneer or solid wood applied to the edges of panels, providing enhanced strength and a seamless, natural appearance. Unlike edge banding, which is typically a thin laminate strip glued to the surface, solid edge offers superior protection against chipping and moisture damage, making it ideal for high-quality furniture and cabinetry. When choosing your woodworking materials, consider solid edge for its robustness and aesthetic value in achieving a professional finish.

Key Material Differences

Edge banding consists of thin strips of material such as PVC, ABS, or wood veneer applied to cover the exposed edges of plywood or MDF, offering a smooth and cost-effective finish. Solid edge, made from a continuous piece of solid wood, provides superior durability, natural appearance, and resistance to chipping and moisture. Material thickness and composition significantly affect the edge strength, with solid edges typically being thicker and more robust than the thinner, flexible strips used in edge banding.

Aesthetic Comparison: Edge Banding vs Solid Edge

Edge banding offers a smooth, consistent finish with seamless patterns that closely mimic wood grain or other materials, enhancing visual uniformity on furniture surfaces. Solid edge provides a robust, natural look with genuine wood thickness on the edges, showcasing authentic grain and texture for a more premium aesthetic. You should choose edge banding for cost-effective versatility or solid edge to achieve a high-end, durable design with superior visual depth.

Durability and Longevity

Edge banding offers moderate durability and is prone to peeling or chipping over time, especially in high-moisture or heavily used environments. Solid edge provides superior longevity due to its thicker material and robust construction, resisting wear, impact, and moisture more effectively. For applications requiring extended durability, solid edge remains the preferred choice over edge banding.

Cost Considerations

Edge banding offers a cost-effective solution by providing an affordable way to cover raw plywood or MDF edges, significantly reducing material expenses compared to solid edge options. Solid edge, made from continuous strips of hardwood or PVC, typically incurs higher costs due to the quality of raw materials and labor-intensive installation. Budget-conscious projects favor edge banding for its economic advantages without compromising on aesthetic appeal and durability.

Installation Methods and Labor

Edge banding installation involves applying thin strips of material such as PVC or wood veneer using heat or adhesives, making it a quicker process that requires less skilled labor compared to solid edge installation. Solid edge installation demands precise cutting and joining of solid wood strips, often necessitating specialized tools and experienced craftsmen, resulting in higher labor costs and longer installation times. Your project's budget and timeline may benefit from edge banding's efficient installation methods, especially in large-scale or less intricate applications.

Best Applications for Each Technique

Edge banding is best suited for cost-effective furniture manufacturing and cabinetry where quick application and moisture resistance are essential, especially on particleboard or MDF surfaces. Solid edge is ideal for high-end woodworking projects requiring durability, seamless aesthetics, and enhanced structural integrity, such as custom hardwood tables or countertops. Choosing between these techniques depends on budget constraints, desired finish quality, and material compatibility.

Summary: Choosing the Right Edge Solution

Edge banding offers a cost-effective, versatile solution for covering raw edges, providing moisture resistance and a seamless aesthetic that suits most cabinetry and furniture applications. Solid edge, made from solid wood strips, offers superior durability and can be sanded or refinished, making it ideal for high-traffic surfaces requiring long-term resilience. Selecting the right edge solution depends on budget, durability needs, and the desired finish quality, with edge banding excelling in affordability and design variety, while solid edge outperforms in strength and repairability.

Edge Banding vs Solid Edge Infographic

libmatt.com

libmatt.com