Straight grain fabric runs parallel to the lengthwise threads, providing maximum strength, stability, and minimal stretch, ideal for structured garments and precise sewing. Cross grain, running perpendicular to the straight grain, offers more flexibility and slight stretch, making it suitable for designs requiring drape and comfort, so choosing the right grain affects your garment's fit and durability.

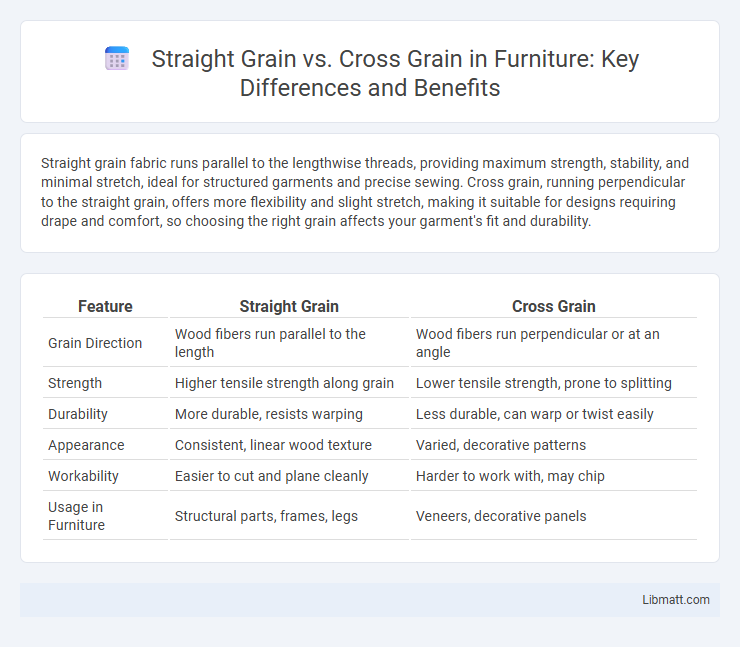

Table of Comparison

| Feature | Straight Grain | Cross Grain |

|---|---|---|

| Grain Direction | Wood fibers run parallel to the length | Wood fibers run perpendicular or at an angle |

| Strength | Higher tensile strength along grain | Lower tensile strength, prone to splitting |

| Durability | More durable, resists warping | Less durable, can warp or twist easily |

| Appearance | Consistent, linear wood texture | Varied, decorative patterns |

| Workability | Easier to cut and plane cleanly | Harder to work with, may chip |

| Usage in Furniture | Structural parts, frames, legs | Veneers, decorative panels |

Understanding Grain Direction: Straight Grain vs Cross Grain

Understanding grain direction is essential for fabric cutting and garment construction; straight grain runs parallel to the selvage, providing stability and less stretch, which ensures garments maintain their shape and drape properly. Cross grain runs perpendicular to the selvage, offering more stretch and flexibility but less structural integrity, making it ideal for design elements requiring movement or elasticity. Proper alignment with the straight grain improves durability and appearance, while cross grain can enhance comfort and fit in specific garment areas.

Defining Straight Grain: Characteristics and Uses

Straight grain refers to fabric threads that run parallel to each other lengthwise, providing maximum strength and stability. This type of grain is ideal for garment construction as it ensures the fabric drapes smoothly and maintains shape over time. Your sewing projects benefit from using straight grain fabric for precise cutting and consistent seam alignment.

What is Cross Grain? Features and Applications

Cross grain refers to the orientation of fabric threads running perpendicular to the straight grain, typically across the width of the material. It features greater stretchability and flexibility due to the looser weave of weft threads, making it ideal for garments requiring ease of movement and comfort. Common applications include bias cuts, sleeves, collars, and tailoring details that benefit from enhanced drape and shape retention.

Strength and Stability: Comparing Grain Directions

Straight grain wood exhibits superior strength and stability due to the alignment of fibers parallel to the board's length, maximizing load-bearing capacity and minimizing warping. Cross grain wood, with fibers oriented perpendicular to the length, reduces the risk of splitting but compromises overall strength and dimensional stability under stress. Understanding grain direction is crucial for applications requiring precise structural integrity and long-term durability in woodworking and construction.

Visual Appeal: Aesthetic Differences

Straight grain fabric displays a uniform, linear pattern that enhances the sleek, polished appearance of garments, making them look more structured and tailored. Cross grain fabric exhibits a subtle diagonal or varied texture, lending designs a dynamic, textured visual appeal that adds depth and interest. The choice between straight grain and cross grain significantly impacts the overall aesthetic, influencing how light reflects and how patterns align on the finished product.

Cutting Techniques for Straight and Cross Grain

Cutting on the straight grain ensures fabric stability and prevents distortion, making your sewing projects more durable and precise. Cross grain cutting offers greater stretch and drape, ideal for garments requiring flexibility and movement. Choosing the correct cutting technique based on grain direction is essential for achieving the desired fit and fabric performance.

Impact on Fabric and Woodworking Projects

Straight grain in fabric and woodworking ensures strength and stability, providing durability and a clean, consistent appearance for your projects. Cross grain introduces more flexibility in fabric but can weaken woodworking pieces, leading to increased risk of warping or distortion. Understanding grain direction optimizes the performance and longevity of your materials.

Durability and Wear Resistance: Which Grain Wins?

Straight grain fabrics exhibit superior durability and wear resistance compared to cross grain due to the alignment of fibers running parallel to the fabric's length, minimizing stretch and deformation. Cross grain, with fibers running perpendicular, tends to offer more flexibility but less structural strength, leading to quicker wear under stress. For your projects demanding long-lasting performance, choosing straight grain ensures enhanced resilience and sustained fabric integrity.

Choosing the Right Grain for Your Project

Choosing the right grain for your woodworking project influences strength, appearance, and ease of cutting. Straight grain offers uniform texture and superior strength, ideal for structural components and smooth finishes. Cross grain presents varied patterns and can add visual interest but may be prone to splintering or warping, making it better suited for decorative elements.

Tips for Working with Straight and Cross Grain

Working with straight grain ensures fabric stability and reduces distortion, so always align patterns parallel to the selvage for best results. When handling cross grain, expect more stretch and adjust cutting techniques by stabilizing edges and using tailor's tape to maintain shape. Use a sharp rotary cutter and pressing techniques to prevent fabric shifting and achieve precise seams on both straight and cross grain fabrics.

Straight grain vs cross grain Infographic

libmatt.com

libmatt.com