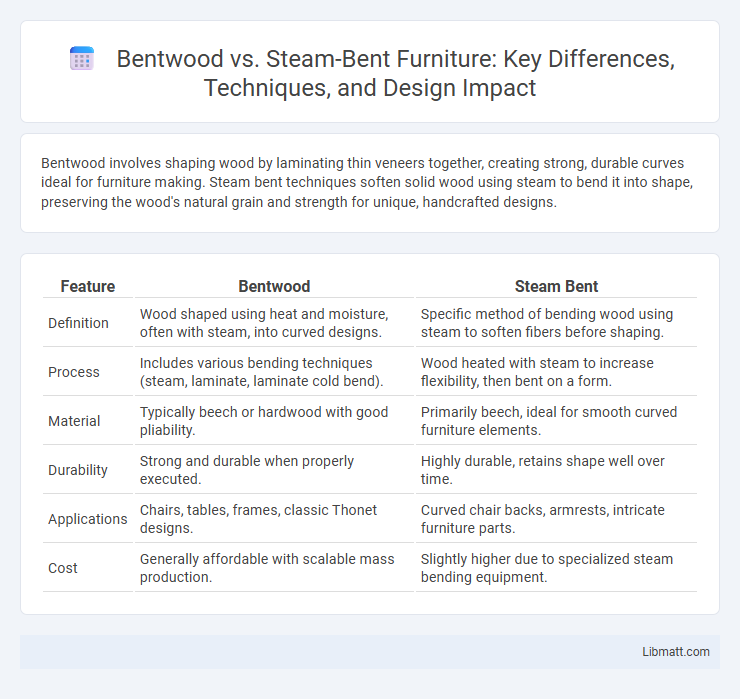

Bentwood involves shaping wood by laminating thin veneers together, creating strong, durable curves ideal for furniture making. Steam bent techniques soften solid wood using steam to bend it into shape, preserving the wood's natural grain and strength for unique, handcrafted designs.

Table of Comparison

| Feature | Bentwood | Steam Bent |

|---|---|---|

| Definition | Wood shaped using heat and moisture, often with steam, into curved designs. | Specific method of bending wood using steam to soften fibers before shaping. |

| Process | Includes various bending techniques (steam, laminate, laminate cold bend). | Wood heated with steam to increase flexibility, then bent on a form. |

| Material | Typically beech or hardwood with good pliability. | Primarily beech, ideal for smooth curved furniture elements. |

| Durability | Strong and durable when properly executed. | Highly durable, retains shape well over time. |

| Applications | Chairs, tables, frames, classic Thonet designs. | Curved chair backs, armrests, intricate furniture parts. |

| Cost | Generally affordable with scalable mass production. | Slightly higher due to specialized steam bending equipment. |

Introduction to Bentwood and Steam Bent Techniques

Bentwood and steam bent techniques both involve shaping wood through controlled bending processes, but they differ in method and application. Bentwood uses thin, flexible wood layers glued together and molded into shape, providing durability and precision, while steam bent wood is softened by steam to increase flexibility before being bent into curves, allowing for natural grain patterns and strength retention. Understanding these techniques helps you choose the best approach for your woodworking projects based on desired aesthetics and structural properties.

Historical Background of Wood Bending

Bentwood furniture dates back to the 19th century, with Michael Thonet pioneering the technique by using steam to soften beech wood for shaping durable, lightweight pieces. Steam bending, an ancient woodworking method, involves heating wood with steam to increase flexibility, allowing craftsmen to create complex curves without breaking the grain. Understanding the historical advancements in these techniques can enhance your appreciation for the craftsmanship behind curved wood furniture.

Understanding Bentwood: Process and Applications

Bentwood involves shaping wood by soaking or steaming it until pliable, then bending it into curved forms used primarily in furniture and musical instruments. The steam bent method uses steam to heat wood fibers, allowing precise and durable bends ideal for chair frames and boat ribs. Understanding these processes helps you choose the right technique for crafting sturdy, aesthetically pleasing wooden designs.

Exploring Steam Bent Woodwork

Steam bent woodwork involves softening hardwood by exposing it to steam, allowing craftsmen to shape durable, flexible curves without compromising structural integrity. This technique contrasts with traditional bentwood methods that often rely on laminating thin wood strips, offering greater strength and uniformity in curved components. Steam bending is essential for creating strong, resilient furniture and boat parts, highlighting its significance in sustainable and efficient woodworking practices.

Key Differences Between Bentwood and Steam Bent

Bentwood involves shaping wood using heat and moisture, often with steam, to create curved forms; steam bent specifically refers to using steam as the moistening agent to increase wood pliability. Key differences include the source of moisture--bentwood may utilize boiling water, soaking, or other methods beyond steam--and the precision of control, with steam bent wood allowing for more consistent and uniform bending due to regulated steam application. These techniques impact applications in furniture making, musical instruments, and architectural components, with steam bent wood typically favored for complex, tight curves requiring structural integrity.

Material Suitability for Each Method

Bentwood techniques typically utilize hardwoods such as beech, oak, and ash due to their strength and flexibility, making them ideal for steam bending applications. Steam bending requires wood that can withstand moisture and heat without cracking, with species like white oak and hickory demonstrating excellent pliability and resilience. Softer woods may not hold shape well, while hardwoods with tight grain structures provide superior durability and form retention after bending.

Design Versatility and Aesthetic Outcomes

Bentwood offers a broader design versatility with its ability to create smooth, continuous curves through molded veneer techniques, allowing for lightweight yet sturdy furniture pieces ideal for modern and classic aesthetics. Steam bent wood provides a more natural grain pattern and organic shapes, enhancing rustic and artisanal designs while maintaining structural integrity through controlled softening and shaping of solid wood. Both methods enable distinct aesthetic outcomes: bentwood emphasizes elegance and fluid form, whereas steam bent wood highlights natural textures and handcrafted charm.

Durability and Structural Strength Comparison

Bentwood furniture, crafted by bending solid wood using gentle heat or moisture, offers moderate durability with a smooth, flexible finish that maintains structural integrity under regular use. Steam bent wood, subjected to more intense steam treatment, enhances wood pliability, resulting in stronger curves and superior resilience against cracking and warping, thereby providing increased structural strength and longevity. The steam bending process typically produces furniture with higher load-bearing capacity and greater resistance to environmental stress compared to traditional bentwood methods.

Cost and Production Time Factors

Bentwood furniture typically costs less due to its simpler production process involving pre-formed, laminated wood layers, reducing labor and material expenses. Steam bent wood requires longer production times as it involves heating and bending solid wood pieces, demanding skilled craftsmanship and careful moisture control. Your choice between bentwood and steam bent methods directly impacts both budget and delivery schedules, depending on the complexity and scale of your project.

Choosing the Right Technique for Your Project

Bentwood involves shaping wood by soaking it in water and then bending it around a form, making it ideal for lightweight, curved furniture and decorative pieces. Steam bending uses steam to soften wood fibers, allowing for more flexibility and strength, which suits complex, load-bearing structures like chair frames or architectural elements. Your choice depends on project requirements such as wood type, desired durability, and complexity of curves.

Bentwood vs Steam Bent Infographic

libmatt.com

libmatt.com