Water-based finishes offer low odor, quick drying times, and easy cleanup with water, making them ideal for indoor projects and environmentally conscious users. Solvent-based finishes provide a durable, high-gloss coating that penetrates deeply for enhanced protection and longevity, suitable for heavy-use surfaces where robust resistance is essential.

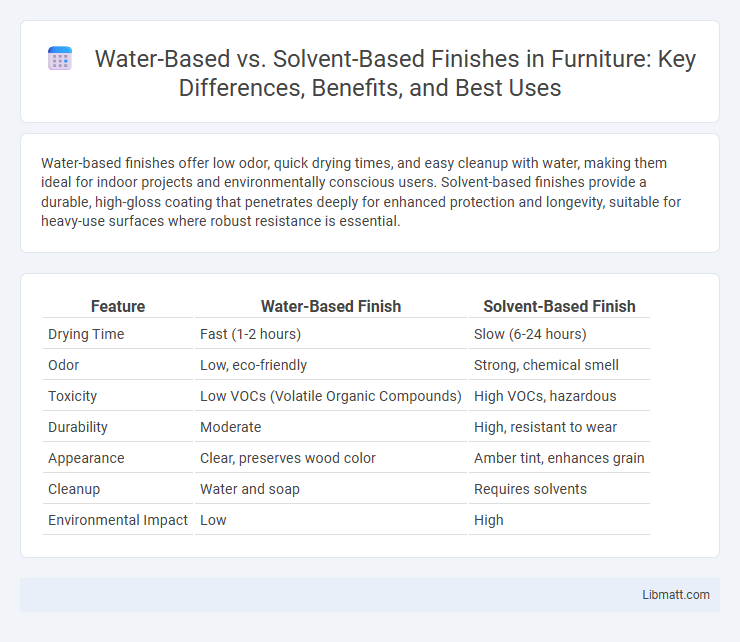

Table of Comparison

| Feature | Water-Based Finish | Solvent-Based Finish |

|---|---|---|

| Drying Time | Fast (1-2 hours) | Slow (6-24 hours) |

| Odor | Low, eco-friendly | Strong, chemical smell |

| Toxicity | Low VOCs (Volatile Organic Compounds) | High VOCs, hazardous |

| Durability | Moderate | High, resistant to wear |

| Appearance | Clear, preserves wood color | Amber tint, enhances grain |

| Cleanup | Water and soap | Requires solvents |

| Environmental Impact | Low | High |

Introduction to Water-Based and Solvent-Based Finishes

Water-based finishes use water as the primary solvent, offering low VOC emissions and quick drying times, making them eco-friendly and safer for indoor use. Solvent-based finishes rely on chemical solvents like mineral spirits, providing a durable, glossy coat with superior resistance to wear and chemicals but typically emit higher levels of volatile organic compounds (VOCs). Your choice between water-based and solvent-based finishes depends on factors such as environmental impact, drying time, and the desired durability for your project.

Composition and Chemical Differences

Water-based finishes primarily consist of acrylic or polyurethane polymers suspended in water, resulting in lower levels of volatile organic compounds (VOCs) and faster drying times. Solvent-based finishes contain hydrocarbons or other organic solvents that dissolve resins and binders, providing a more durable, glossy coating but emitting higher VOC levels and stronger odors. The chemical makeup of water-based finishes emphasizes environmental safety and ease of cleanup, while solvent-based finishes rely on chemical solvents for enhanced hardness and resistance.

Application Process: What to Expect

Water-based finishes typically dry faster and emit fewer volatile organic compounds (VOCs), making the application process cleaner and more environmentally friendly. Solvent-based finishes require longer drying times and often need multiple coats with adequate ventilation due to stronger odors and higher VOC levels. Both finishes benefit from proper surface preparation and the use of high-quality brushes or sprayers to ensure smooth, even coverage.

Drying and Curing Times Compared

Water-based finishes dry significantly faster than solvent-based finishes, often within 1 to 2 hours, while solvent-based finishes can take 6 to 8 hours or more to dry. Curing times for water-based finishes typically range from 7 to 14 days, providing quicker recoat times and use, whereas solvent-based finishes may require up to 30 days to fully cure for maximum durability. The faster drying and curing times of water-based finishes reduce downtime and exposure to strong odors and volatile organic compounds (VOCs).

Environmental Impact and VOC Emissions

Water-based finishes have a significantly lower environmental impact due to reduced volatile organic compound (VOC) emissions, making them a safer choice for indoor air quality and overall ecosystem health. Solvent-based finishes release higher levels of VOCs, contributing to air pollution and posing health risks such as respiratory issues and headaches. Choosing water-based finishes helps you minimize your carbon footprint and supports sustainable practices in wood treatment.

Durability and Longevity of Each Finish

Water-based finishes offer excellent durability with resistance to yellowing and wear, making them ideal for maintaining the appearance of light wood over time. Solvent-based finishes typically provide superior longevity and a harder, more abrasion-resistant surface, suitable for high-traffic areas or heavy-use furniture. Your choice depends on the balance between environmental considerations and the desired durability for the specific application.

Appearance: Color and Sheen Variations

Water-based finishes typically offer a clearer, more natural appearance with enhanced color depth and a softer sheen, preserving the wood's original tones. Solvent-based finishes tend to impart a warmer hue and richer gloss, accentuating wood grain with stronger amber undertones. Your choice between these finishes impacts the final aesthetic, balancing color vibrancy and desired sheen for your project.

Maintenance and Cleaning Requirements

Water-based finishes require simpler maintenance with mild soap and water, reducing the risk of damage to the surface and promoting a longer-lasting appearance. Solvent-based finishes demand tougher, solvent-based cleaners for effective removal of dirt and grime, which can sometimes lead to faster wear or chemical degradation. Regular cleaning schedules and appropriate product selection are essential to preserve the integrity and look of both finish types.

Cost Analysis: Upfront and Long-Term

Water-based finishes offer a lower upfront cost due to reduced material toxicity and easier cleanup, making them cost-effective for initial project expenses. Solvent-based finishes may have higher upfront costs but can provide greater durability and longer-lasting protection, potentially reducing long-term maintenance and refinishing expenses. Your choice should balance immediate budget constraints with anticipated lifespan and upkeep needs for optimal cost efficiency.

Choosing the Right Finish for Your Project

Selecting the right finish for your project depends on factors like desired appearance, durability, and environmental impact. Water-based finishes offer low VOC emissions, quick drying times, and a clear, non-yellowing coat, ideal for indoor applications. Solvent-based finishes provide superior durability and a richer color depth, making them suitable for high-traffic or exterior projects where longevity is crucial.

Water-Based vs Solvent-Based Finish Infographic

libmatt.com

libmatt.com