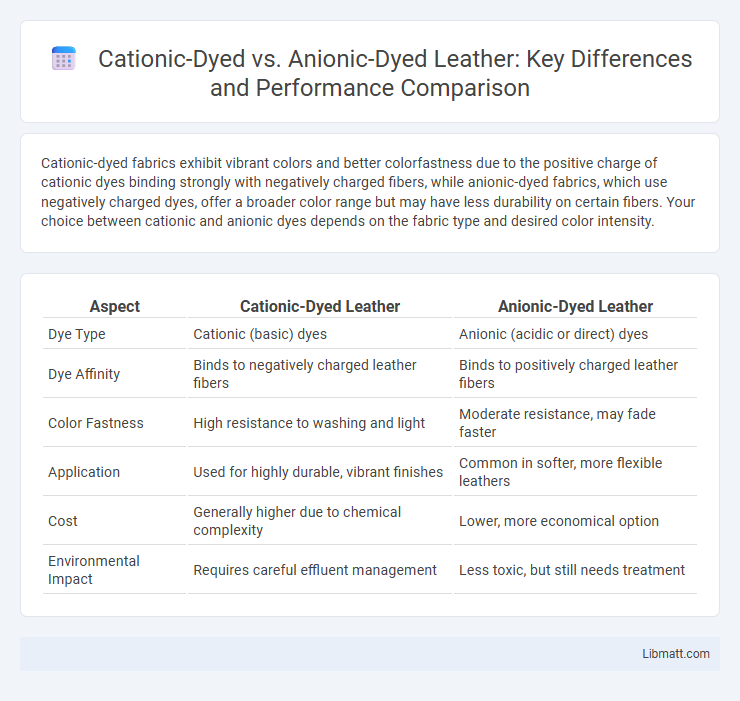

Cationic-dyed fabrics exhibit vibrant colors and better colorfastness due to the positive charge of cationic dyes binding strongly with negatively charged fibers, while anionic-dyed fabrics, which use negatively charged dyes, offer a broader color range but may have less durability on certain fibers. Your choice between cationic and anionic dyes depends on the fabric type and desired color intensity.

Table of Comparison

| Aspect | Cationic-Dyed Leather | Anionic-Dyed Leather |

|---|---|---|

| Dye Type | Cationic (basic) dyes | Anionic (acidic or direct) dyes |

| Dye Affinity | Binds to negatively charged leather fibers | Binds to positively charged leather fibers |

| Color Fastness | High resistance to washing and light | Moderate resistance, may fade faster |

| Application | Used for highly durable, vibrant finishes | Common in softer, more flexible leathers |

| Cost | Generally higher due to chemical complexity | Lower, more economical option |

| Environmental Impact | Requires careful effluent management | Less toxic, but still needs treatment |

Introduction to Cationic and Anionic Dyeing

Cationic dyeing involves positively charged dye molecules that strongly attract negatively charged fibers, enhancing dye uptake and color fastness in synthetic textiles like acrylics. Anionic dyeing uses negatively charged dye molecules that bind effectively to positively charged fiber sites, commonly used for dyeing natural fibers such as wool and silk. Understanding the ionic interactions between dye molecules and fiber surfaces is crucial for optimizing color vibrancy and durability in textile manufacturing.

Chemical Structure and Composition

Cationic-dyed fibers contain positively charged groups that attract and bind to negatively charged dye molecules, enhancing dye affinity and colorfastness. Anionic-dyed fibers possess negatively charged sites that interact with positively charged dyes, typically involving sulfonate or carboxyl groups in their chemical structure. Understanding the chemical composition of these fibers helps optimize your dyeing process for improved color vibrancy and durability.

Dyeing Mechanism: How Do They Work?

Cationic-dyed fibers attract negatively charged dye molecules through electrostatic forces, enabling strong ionic bonds that result in vibrant, long-lasting colors. Anionic-dyed fibers, on the other hand, bind positively charged dyes primarily via van der Waals forces and hydrogen bonding, offering different colorfastness properties. Understanding the dyeing mechanism helps you optimize fabric selection based on the desired durability and color intensity.

Suitable Fibers for Each Dye Type

Cationic dyes are primarily suitable for acrylic fibers due to their positive charge, which forms strong ionic bonds with the anionic sites on these fibers, resulting in vibrant and wash-fast colors. Anionic dyes, including acid and reactive dyes, are best suited for fibers such as wool, silk, nylon, and cellulose-based materials like cotton, where the negatively charged dye molecules effectively bind to the positively charged or reactive sites on these fibers. The compatibility between dye type and fiber chemistry ensures optimal dye uptake, colorfastness, and overall fabric performance.

Color Fastness and Durability Comparison

Cationic-dyed fabrics exhibit superior color fastness due to stronger ionic bonds between dye molecules and fiber, resulting in enhanced resistance to washing and light exposure. Anionic-dyed materials often show moderate color retention but are more susceptible to fading and washing out because of weaker chemical interactions with fibers. Durability in cationic-dyed textiles generally surpasses that of anionic-dyed counterparts, maintaining vivid colors and structural integrity over extended use.

Environmental Impact of Cationic vs Anionic Dyes

Cationic dyes generally exhibit lower environmental toxicity due to their higher fixation rates on substrates, resulting in less dye effluent contamination compared to anionic dyes, which often require more extensive chemical treatments for wastewater management. Anionic dyes, especially azo and reactive dyes, can produce persistent synthetic compounds that pose greater challenges in biodegradability and water pollution control. Your choice between cationic and anionic dyes directly influences the sustainability of textile dyeing processes and the reduction of hazardous dye residues in aquatic ecosystems.

Cost and Efficiency in Industrial Applications

Cationic-dyed fabrics generally incur higher initial costs due to specialized dye formulations but offer superior colorfastness and energy efficiency in industrial applications. Anionic-dyed materials tend to be more cost-effective upfront with widespread availability but may require additional processing steps, increasing overall operational expenses. Efficiency gains with cationic dyes include reduced water usage and lower chemical waste, enhancing sustainability in large-scale textile manufacturing.

Key Advantages of Cationic Dyeing

Cationic dyeing offers superior color fastness and vibrancy compared to anionic dyeing, making it ideal for synthetic fibers like polyester. The process enhances dye uptake efficiency, reducing water and energy consumption while promoting eco-friendly textile production. Your fabrics benefit from improved durability and brighter, long-lasting colors with cationic dyes.

Key Advantages of Anionic Dyeing

Anionic dyeing offers superior colorfastness and resistance to washing, fading, and light exposure compared to cationic dyeing. It provides a broader spectrum of vibrant and uniform hues on natural and synthetic fibers due to stronger ionic bonding with fiber molecules. The process also ensures better environmental performance by reducing water and chemical consumption during dye fixation.

Choosing the Right Dyeing Method for Your Needs

Choosing the right dyeing method depends on the fabric type and desired colorfastness. Cationic-dyed fabrics provide vibrant, long-lasting colors by binding positively charged dye ions to fibers like polyester, making them ideal for synthetic materials. Anionic-dyed fabrics use negatively charged dyes suitable for natural fibers such as cotton, offering excellent wash and light fastness, which ensures your garments maintain their appearance over time.

Cationic-dyed vs anionic-dyed Infographic

libmatt.com

libmatt.com