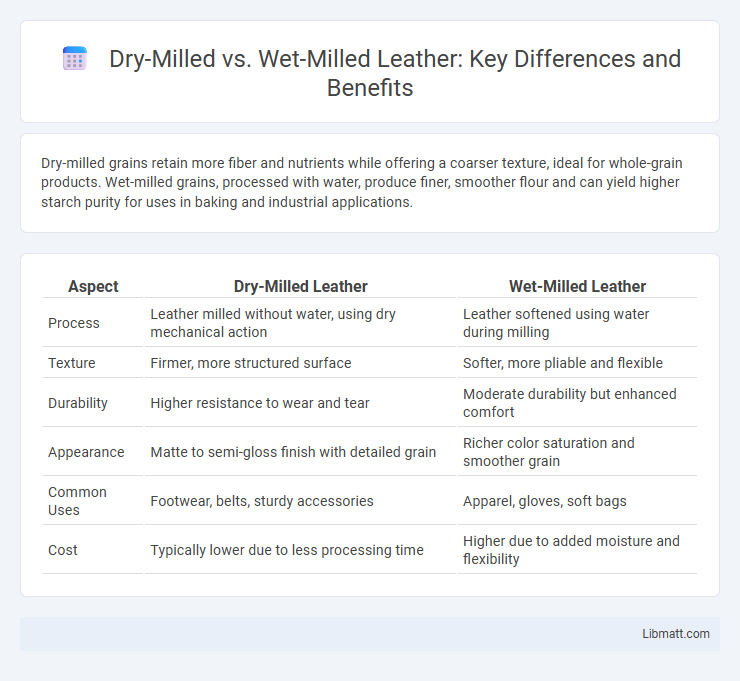

Dry-milled grains retain more fiber and nutrients while offering a coarser texture, ideal for whole-grain products. Wet-milled grains, processed with water, produce finer, smoother flour and can yield higher starch purity for uses in baking and industrial applications.

Table of Comparison

| Aspect | Dry-Milled Leather | Wet-Milled Leather |

|---|---|---|

| Process | Leather milled without water, using dry mechanical action | Leather softened using water during milling |

| Texture | Firmer, more structured surface | Softer, more pliable and flexible |

| Durability | Higher resistance to wear and tear | Moderate durability but enhanced comfort |

| Appearance | Matte to semi-gloss finish with detailed grain | Richer color saturation and smoother grain |

| Common Uses | Footwear, belts, sturdy accessories | Apparel, gloves, soft bags |

| Cost | Typically lower due to less processing time | Higher due to added moisture and flexibility |

Introduction to Dry-Milled vs Wet-Milled Processes

Dry-milled and wet-milled processes differ primarily in how raw materials like corn or grains are prepared and processed for various applications. Dry-milling involves grinding the entire grain without soaking, resulting in products like flour and grits, while wet-milling uses water or steam to soften kernels, facilitating separation into components such as starch, protein, and fiber. Understanding these distinct techniques is essential for industries like biofuel production, food processing, and feed manufacturing, as each method impacts yield, product quality, and energy consumption.

Defining Dry Milling and Its Applications

Dry milling is a process that involves grinding grains or seeds without the use of water, preserving the natural moisture content and resulting in a finer, drier product ideal for storage and transport. Commonly applied in cereal grain processing, dry milling produces flour, grits, and meal used extensively in baking, brewing, and biofuel industries. This technique enhances shelf life and maintains nutritional integrity by minimizing moisture-induced spoilage and microbial growth.

Understanding Wet Milling: Process and Uses

Wet milling involves soaking grains or seeds in water to soften them before grinding, enhancing nutrient extraction and improving texture for various applications. This process is widely used in the production of starch, ethanol, and animal feed due to its efficiency in separating valuable components like oil, protein, and fiber. Understanding wet milling can help you choose the right technique for maximizing yield and quality in food processing or industrial uses.

Key Differences Between Dry and Wet Milling

Dry-milled and wet-milled processes differ primarily in moisture content and application; dry milling grinds materials without added water, resulting in finer, powdery products often used for flour or grain processing. Wet milling involves soaking materials in water before grinding, producing starch, oil, and protein fractions, crucial for food, biofuel, and industrial uses. Your choice between dry and wet milling depends on the desired product quality, moisture sensitivity, and downstream processing requirements.

Advantages of Dry Milling

Dry milling offers significant advantages such as lower energy consumption and reduced water usage, making the process more environmentally friendly and cost-effective. It simplifies processing by eliminating the need for drying after milling, which accelerates production time and minimizes operational complexity. Your choice of dry milling can enhance sustainability efforts while maintaining high-quality results in grain or biomass processing.

Benefits of Wet Milling

Wet milling improves starch extraction efficiency by utilizing water to separate components, resulting in higher purity and yield. This method enhances the production of refined products like corn syrup and ethanol by reducing fiber contamination. Its ability to process corn kernels without excessive heat preserves nutritional quality and functional properties of the final product.

Common Industries and Materials for Each Method

Dry-milled processes are widely used in industries such as pharmaceuticals and food production, where materials like grains, herbs, and powders require fine, uniform particle size without moisture content. Wet-milled techniques are prevalent in chemical manufacturing, paper production, and ceramics, handling materials like ores, pigments, and clays that benefit from slurry or liquid suspension to enhance grinding efficiency and particle size control. Each method optimizes performance based on the physical properties and moisture sensitivity of the input materials, ensuring suitability for specific industrial applications.

Equipment Used in Dry and Wet Milling

Dry-milled processing employs equipment such as hammer mills, roller mills, and air separators to grind grains into flour or meal without moisture, while wet-milled processing uses steepers, grinders, centrifuges, and hydrocyclones to break down kernels in a water medium for starch, fiber, and protein separation. Dry milling machinery is designed for high-speed grinding and particle size control under dry conditions, whereas wet milling equipment emphasizes soaking, separation, and purification steps to extract various components. Your choice between dry and wet milling depends on the desired end product and production scale, influencing the types of specialized equipment required.

Factors to Consider When Choosing Milling Methods

Choosing between dry-milled and wet-milled processes depends on factors such as the desired particle size, moisture content, and end-product application. Dry milling is suitable for grains with low moisture and produces finer flour, while wet milling is ideal for separating starch, protein, and fiber, often used in industries requiring high-purity components. Evaluating your material properties and processing goals ensures the selection of the optimal milling method for efficiency and product quality.

Future Trends in Milling Technology

Future trends in milling technology emphasize increased automation and precision in both dry-milled and wet-milled processes, enhancing efficiency and product consistency. Innovations such as AI-driven sensors and real-time quality monitoring are set to revolutionize how mills optimize moisture content and particle size. Your choice between dry and wet milling will benefit from smarter systems that reduce waste and improve energy consumption in line with sustainability goals.

Dry-milled vs wet-milled Infographic

libmatt.com

libmatt.com