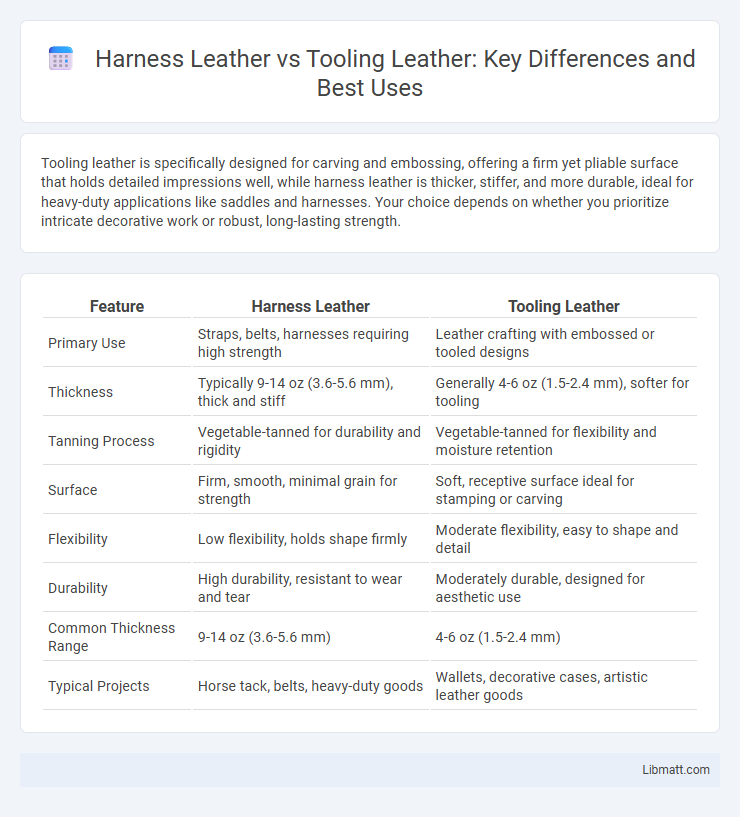

Tooling leather is specifically designed for carving and embossing, offering a firm yet pliable surface that holds detailed impressions well, while harness leather is thicker, stiffer, and more durable, ideal for heavy-duty applications like saddles and harnesses. Your choice depends on whether you prioritize intricate decorative work or robust, long-lasting strength.

Table of Comparison

| Feature | Harness Leather | Tooling Leather |

|---|---|---|

| Primary Use | Straps, belts, harnesses requiring high strength | Leather crafting with embossed or tooled designs |

| Thickness | Typically 9-14 oz (3.6-5.6 mm), thick and stiff | Generally 4-6 oz (1.5-2.4 mm), softer for tooling |

| Tanning Process | Vegetable-tanned for durability and rigidity | Vegetable-tanned for flexibility and moisture retention |

| Surface | Firm, smooth, minimal grain for strength | Soft, receptive surface ideal for stamping or carving |

| Flexibility | Low flexibility, holds shape firmly | Moderate flexibility, easy to shape and detail |

| Durability | High durability, resistant to wear and tear | Moderately durable, designed for aesthetic use |

| Common Thickness Range | 9-14 oz (3.6-5.6 mm) | 4-6 oz (1.5-2.4 mm) |

| Typical Projects | Horse tack, belts, heavy-duty goods | Wallets, decorative cases, artistic leather goods |

Overview: Harness Leather vs Tooling Leather

Harness leather is a thick, durable leather primarily used for making saddles, harnesses, and heavy-duty straps, known for its robust structure and resistance to wear. Tooling leather, often vegetable-tanned and more pliable, is designed specifically for intricate carving and embossing, making it ideal for decorative projects like belts, wallets, and custom leather goods. Both types exhibit distinct qualities optimized for different uses: harness leather emphasizes strength and durability, while tooling leather prioritizes flexibility and detailed artistry.

Defining Harness Leather

Harness leather is a durable, high-quality leather primarily designed for making saddles, tack, and heavy-duty goods, characterized by its thick, stiff texture and excellent resistance to wear and tear. It is typically made from full-grain cowhide, carefully vegetable-tanned to enhance longevity and develop a rich patina over time. Your choice of harness leather guarantees strength and durability for items requiring robust construction and long-lasting performance.

What is Tooling Leather?

Tooling leather is a type of vegetable-tanned cowhide specifically designed for carving and embossing detailed designs, making it ideal for leathercraft projects such as belts, wallets, and saddles. It is softer and more pliable than harness leather, allowing artisans to create intricate patterns using special tools and dyes. Your choice of tooling leather ensures durability while providing a versatile surface for personalized craftsmanship.

Production and Tanning Methods

Harness leather is typically vegetable-tanned using traditional methods that create a dense, durable material ideal for heavy-duty applications like equestrian gear. Tooling leather, also vegetable-tanned, undergoes a specific tanning process that enhances its firmness and pliability to hold detailed impressions and designs. Your choice depends on whether you need a rugged material for strength or a pliable surface suitable for intricate leather crafting.

Key Differences in Texture and Flexibility

Harness leather features a firm, dense texture designed for durability and strength, making it ideal for heavy-duty applications. Tooling leather offers a softer, more pliable surface that allows intricate carving and detailed designs without cracking. The flexibility of tooling leather surpasses that of harness leather, providing artisans greater ease in shaping and embossing.

Durability and Strength Comparison

Harness leather offers superior durability and strength compared to tooling leather due to its thicker, heavier weight and tight grain structure, making it ideal for heavy-duty applications like harnesses and saddles. Tooling leather, while still strong, is softer and more flexible to allow detailed carving and stamping, but it may not withstand as much wear and tear under constant stress. For your projects requiring maximum longevity and toughness, harness leather provides a more robust choice.

Typical Uses and Applications

Harness leather is primarily designed for heavy-duty applications such as horse tack, saddles, and bridles due to its thick, durable, and stiff nature. Tooling leather, often vegetable-tanned with a finer grain, is ideal for crafting detailed designs on belts, wallets, and other leather goods requiring intricate stamping. Choosing the right leather depends on Your project's need for strength versus decorative versatility.

Workability: Cutting, Stamping, and Carving

Harness leather offers superior workability for cutting, stamping, and carving due to its firm, thick structure that maintains shape well under pressure. Tooling leather, typically vegetable-tanned and slightly softer, allows more detailed and intricate carving with easier stamping but may not hold sharp edges as rigidly as harness leather. Both leathers excel in durability, but harness leather is preferred for heavy-duty projects requiring robust cuts and deep impressions.

Maintenance and Care Requirements

Harness leather demands regular cleaning and conditioning to maintain its rigidity and prevent cracking, making it ideal for heavy-duty use. Tooling leather requires frequent moisturizing to preserve its flexibility and enhance the intricate designs carved into its surface. Your care routine should be tailored to the specific leather type to extend durability and appearance.

Choosing the Right Leather for Your Project

Harness leather offers exceptional durability and stiffness, making it ideal for heavy-duty projects like belts and saddles, while tooling leather provides a softer, more pliable surface perfect for intricate carving and design work. Your choice depends on whether you prioritize toughness or detailed craftsmanship, with harness leather excelling in wear resistance and tooling leather allowing for greater artistic expression. Selecting the right leather ensures your project's functionality and aesthetic appeal meet your specific requirements.

Harness leather vs tooling leather Infographic

libmatt.com

libmatt.com